130BE998.10

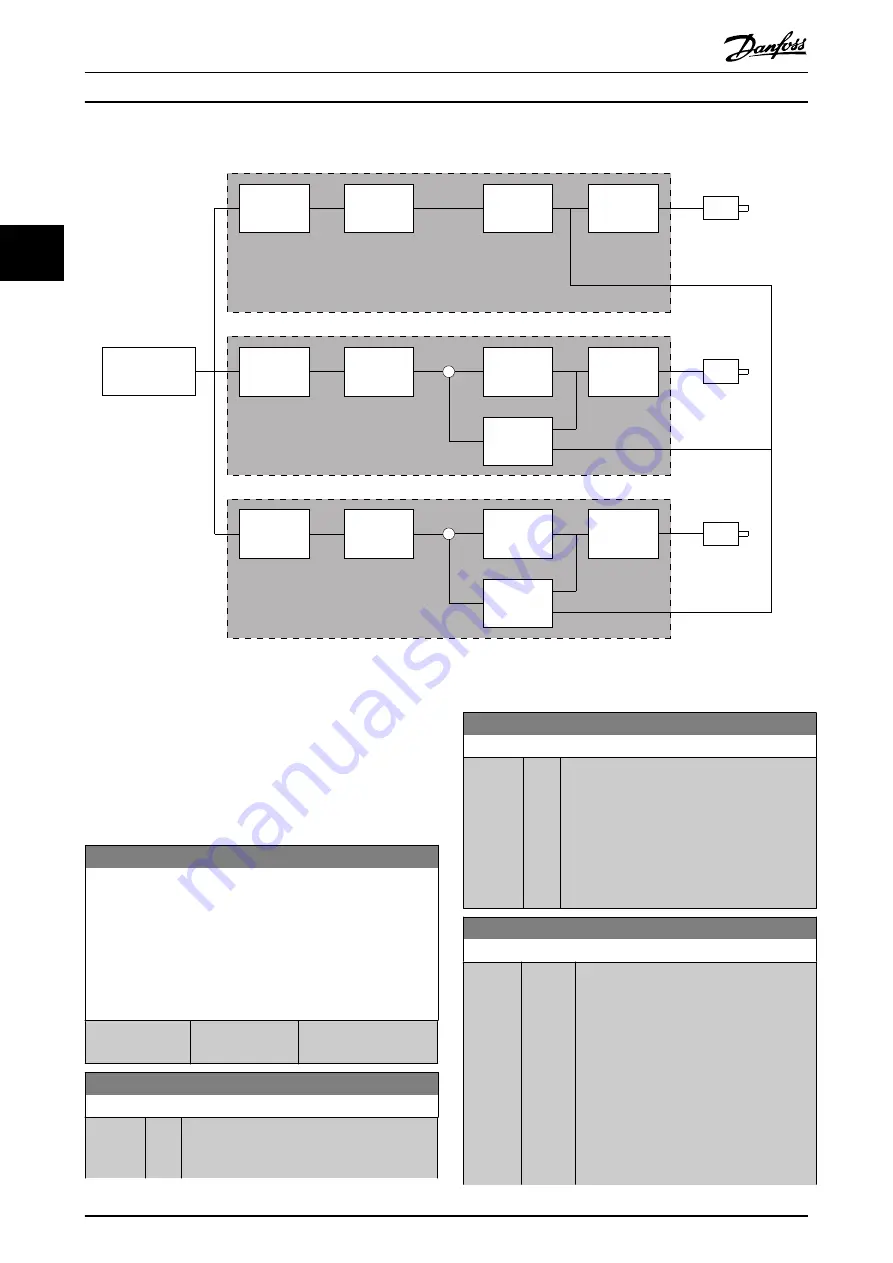

Set-point

Calculation

External Set-point

Ramp

Droop

Speed

PID

Torque

PID

M2

M3

VLT 2

VLT 3

Set-point

Calculation

Ramp

Droop

Speed

PID

-

Set-point

Calculation

Ramp

Speed

PID

Torque

PID

M1

VLT 1

-

Torque

PID

Illustration 3.48 Speed Trim

shows a single source set-up where the

master sends the torque signal to all followers. The

number of available analog outputs on the master limits

this set-up. To overcome the limitation of the number of

analog outputs, use a cascade principle. The cascade

principle makes the control slower and less accurate

compared with the set-up using analog outputs.

7-01 Speed PID Droop

The droop function allows the frequency converter to decrease

the motor speed proportional to the load. The droop value is

directly proportional to the load value. Use the droop function

when several motors are mechanically connected and the load

on motors can differ.

Ensure that

parameter 1-62 Slip Compensation

has a default

setting.

Range:

Function:

0 RPM

*

[0 - 200 RPM]

Enter the droop value at

100% load.

7-02 Speed PID Proportional Gain

Range:

Function:

Size

related

*

[0 -

1 ]

Enter the speed controller proportional gain.

The proportional gain amplifies the error (that

is the deviation between the feedback signal

7-02 Speed PID Proportional Gain

Range:

Function:

and the setpoint). This parameter is used with

parameter 1-00 Configuration Mode

[0] Speed

open loop

and

[1] Speed closed loop

control.

Quick control is obtained at high amplification.

Increasing amplification makes the process less

stable.

For values with 4 decimals, use

parameter 30-83 Speed PID Proportional Gain

.

7-03 Speed PID Integral Time

Range:

Function:

Size

related

*

[1.0 -

20000

ms]

Enter the speed controller integral time,

which determines the time the internal PID

control takes to correct errors. The greater

the error, the more quickly the gain

increases. The integral time causes a delay

of the signal and therefore a dampening

effect and can be used to eliminate steady-

state speed error. Obtain quick control

through a short integral time, though if the

integral time is too short, the process

becomes unstable. An excessively long

integral time disables the integral action,

Parameter Descriptions

VLT

®

AutomationDrive FC 301/302

146

Danfoss A/S © 10/2018 All rights reserved.

MG33MP02

3

3

Содержание VLT AutomationDrive FC 302

Страница 2: ......