To minimise the overshoot,

7-03 Speed PID Integral Time

could be set to approx. 2.5 s (varies with the application).

Set

7-04 Speed PID Differentiation Time

to 0 until everything

else is tuned. If necessary, finish the tuning by experi-

menting with small increments of this setting.

3.6.6.3 Process PID Control

Use the Process PID Control to control application

parameters that can be measured by a sensor (i.e.

pressure, temperature, flow) and be affected by the

connected motor through a pump, fan or otherwise.

shows the control configurations where the

Process Control is possible. When a Flux Vector motor

control principle is used, take care also to tune the Speed

Control PID parameters. Refer to

to see

where the Speed Control is active.

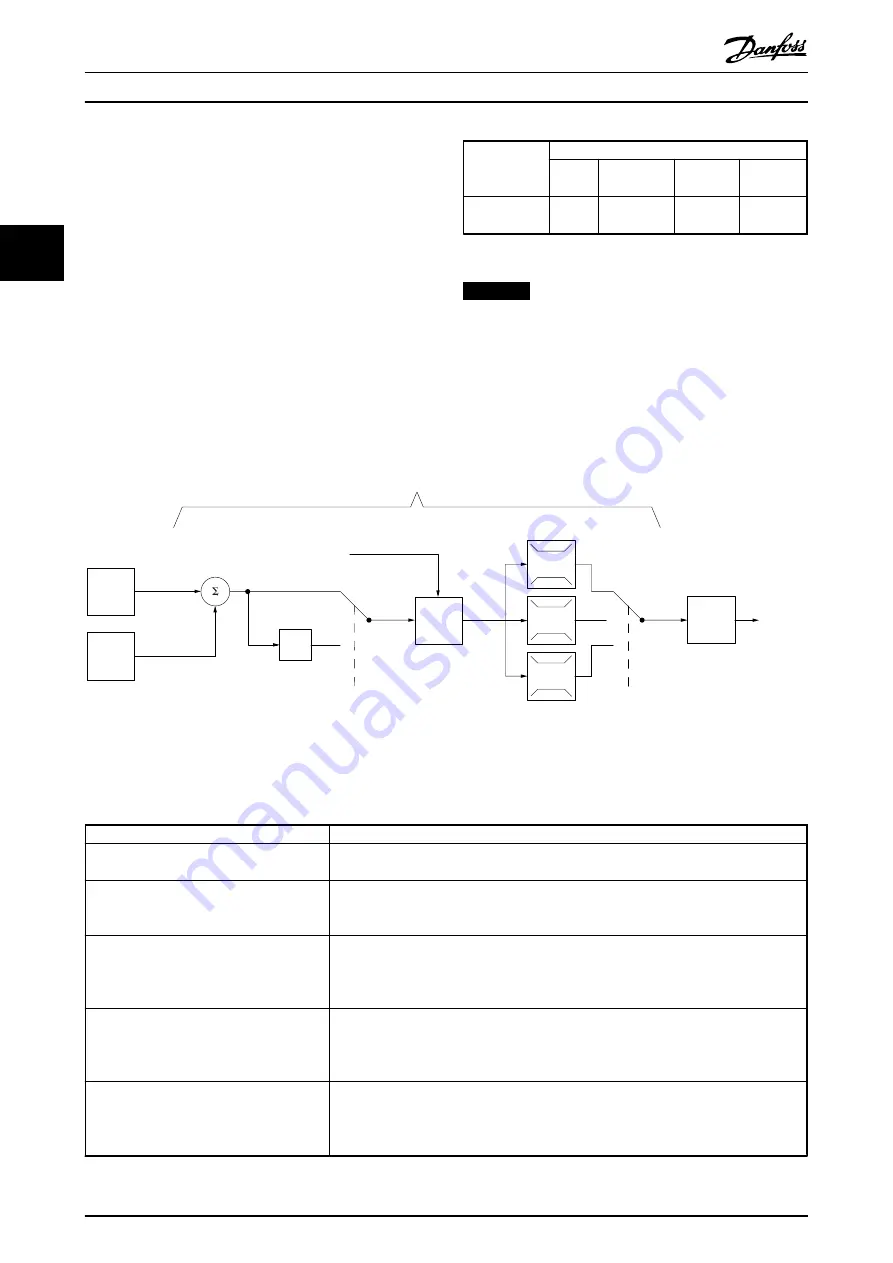

1-00 Configu-

ration Mode

1-01 Motor Control Principle

U/f

VVC

+

Flux

Sensorless

Flux w/

enc. feedb

[3] Process

Not

Active

Process

Process &

Speed

Process &

Speed

Table 3.4 Control Configurations with Process Control

NOTICE

The Process Control PID works under the default

parameter setting, but tuning the parameters is highly

recommended to optimise the application control

performance. The 2 Flux motor control principles are

specially dependant on proper Speed Control PID tuning

(before tuning the Process Control PID) to yield their full

potential.

P 7-30

normal/inverse

PID

P 7-38

*(-1)

Feed forward

Ref.

Handling

Feedback

Handling

% [unit]

% [unit]

%

[unit]

%

[speed]

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

Process PID

130BA178.10

_

+

0%

-100%

100%

0%

-100%

100%

Illustration 3.9 Process PID Control Diagram

sums up the characteristics that can be set up for the process control.

Parameter

Description of function

7-20 Process CL Feedback 1 Resource

Select from which Source (i.e. analog or pulse input) the Process PID should get its

feedback

7-22 Process CL Feedback 2 Resource

Optional: Determine if (and from where) the Process PID should get an additional

feedback signal. If an additional feedback source is selected, the 2 feedback signals are

added together before being used in the Process PID Control.

7-30 Process PID Normal/ Inverse Control

Under

[0] Normal operation

, the Process Control responds with an increase of the motor

speed, if the feedback is getting lower than the reference. In the same situation, but

under

[1] Inverse operation

, the Process Control responds with a decreasing motor speed

instead.

7-31 Process PID Anti Windup

The anti-windup function ensures that when either a frequency limit or a torque limit is

reached, the integrator is set to a gain that corresponds to the actual frequency. This

avoids integrating on an error that cannot in any case be compensated for with a speed

change. This function can be disabled by selecting

[0] Off

.

7-32 Process PID Start Speed

In some applications, reaching the required speed/set point can take a very long time. In

such applications it might be an advantage to set a fixed motor speed from the frequency

converter before the process control is activated. This is done by setting a Process PID

Start Value (speed) in

7-32 Process PID Start Speed

.

Basic Operating Principles

VLT

®

AutomationDrive FC 301/FC 302 Design Guide, 0.25-75 kW

26

MG33BF02 - Rev. 2013-12-20

3

3

Содержание VLT AutomationDrive FC 301

Страница 2: ......

Страница 199: ...Index VLT AutomationDrive FC 301 FC 302 Design Guide 0 25 75 kW MG33BF02 Rev 2013 12 20 197...