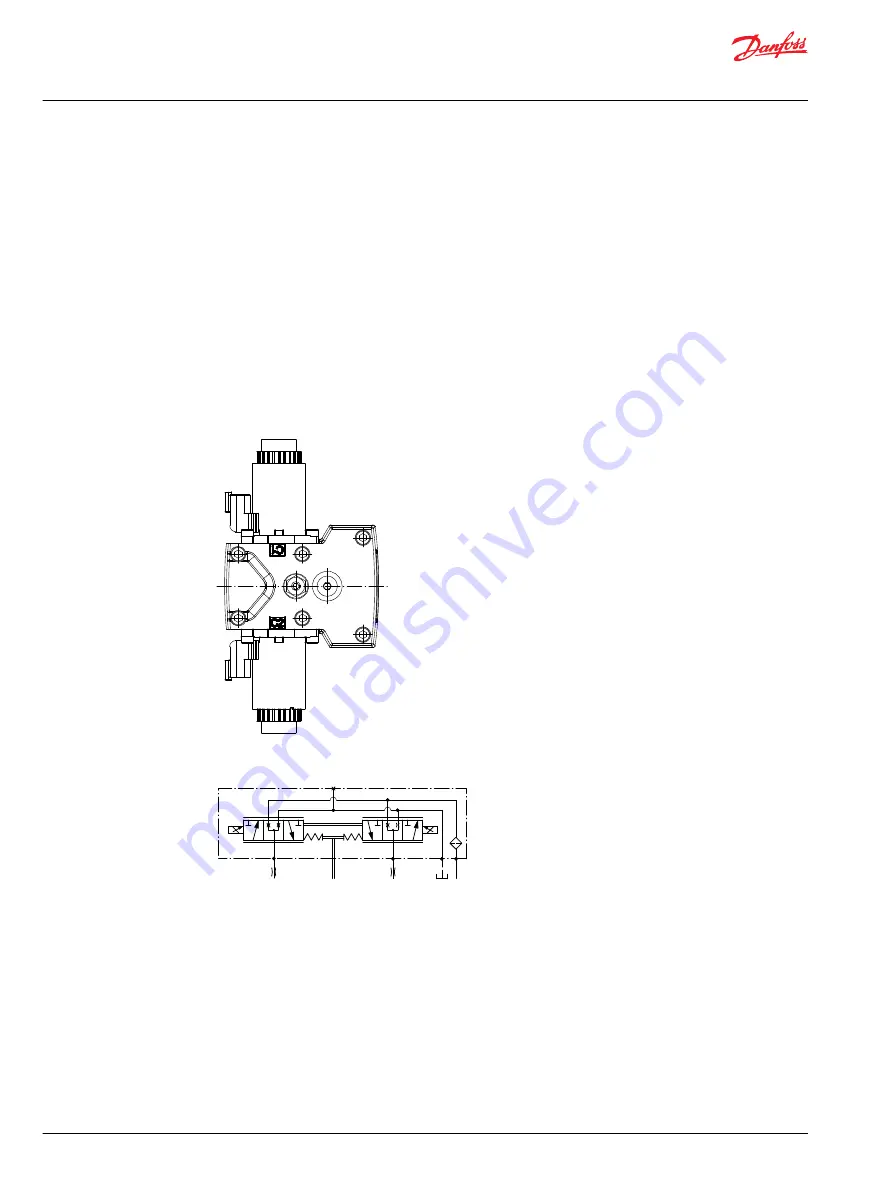

Electrical displacement control (EDC)

EDC principle

An EDC is a displacement (flow) control. Pump swashplate position is proportional to the input command

and therefore vehicle or load speed (excluding influence of efficiency), is dependent only on the prime

mover speed or motor displacement.

The Electrical Displacement Control (EDC) consists of a pair of proportional solenoids on each side of a

three-position, four-way porting spool. The proportional solenoid applies a force input to the spool,

which ports hydraulic pressure to either side of a double acting servo piston. Differential pressure across

the servo piston rotates the swashplate, changing the pump‘s displacement from full displacement in

one direction to full displacement in the opposite direction. Under some circumstances, such as

contamination, the control spool could stick and cause the pump to stay at some displacement.

A 170 μm screen is located in the supply line immediately before the control porting spool.

EDC control

P003 191

EDC schematic

Feedback from

Swash plate

P

T

F00B

M14

C1

C2

F00A

P003 478E

EDC operation

EDC’s are current driven controls requiring a Pulse Width Modulated (PWM) signal. Pulse width

modulation allows more precise control of current to the solenoids. The PWM signal causes the solenoid

pin to push against the porting spool, which pressurizes one end of the servo piston, while draining the

other. Pressure differential across the servo piston moves the swashplate.

A swashplate feedback link, opposing control links, and a linear spring provide swashplate position force

feedback to the solenoid. The control system reaches equilibrium when the position of the swashplate

spring feedback force exactly balances the input command solenoid force from the operator. As

hydraulic pressures in the operating loop change with load, the control assembly and servo/swashplate

system work constantly to maintain the commanded position of the swashplate.

Service Manual

MP1

Operation

14 |

©

Danfoss | April 2019

AX00000244en-000201