Dametric AB

BRM-DM1/2

Installation manual

BRM-DM12 IM EN.docx

October 14, 2019

Page 3 of 6

5 Installation

5.1 General

This manual shows all connections to the module. Some of the functions are however not activated in the

BRM-DM1 variant.

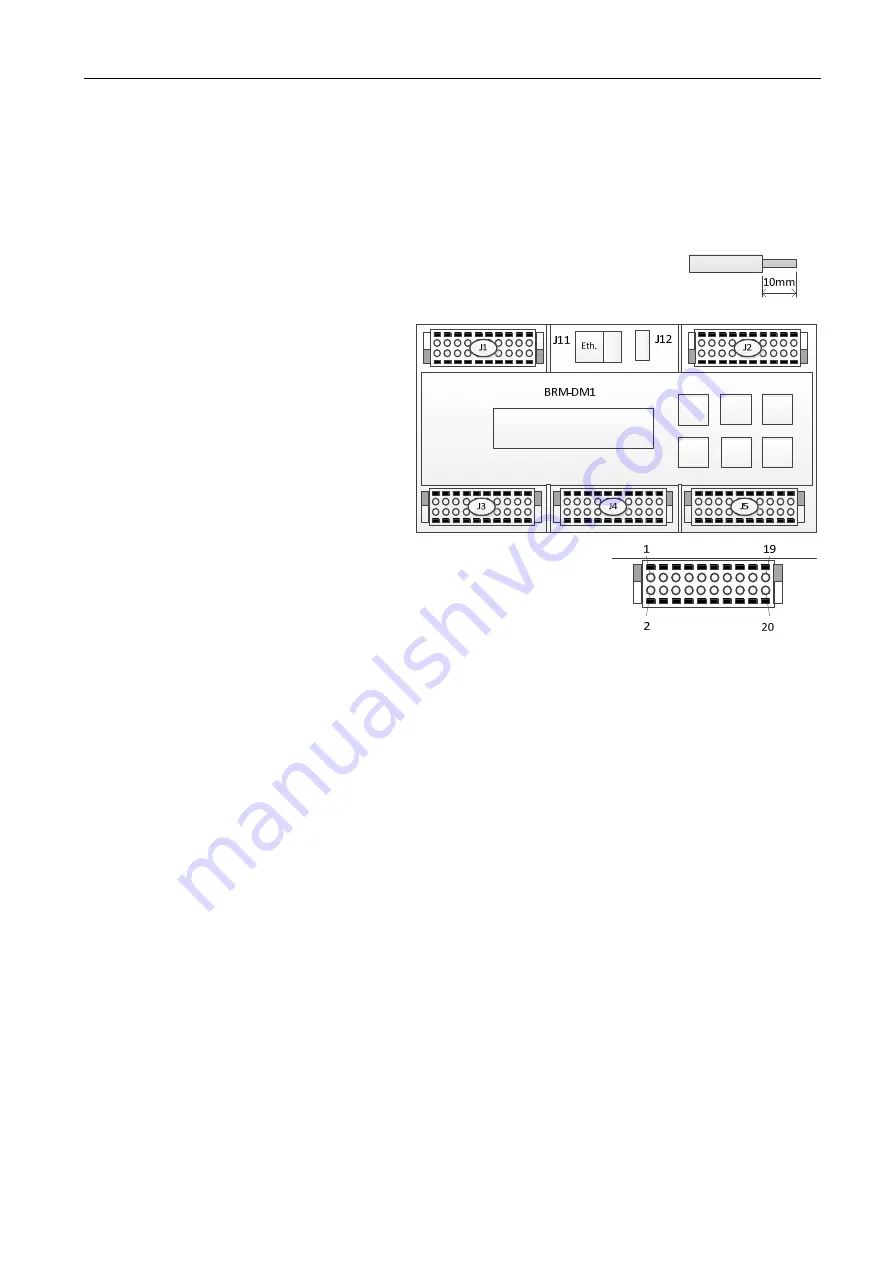

All connections are done to 20-pole connectors with spring loaded sockets.

Maximum allowed conduit area is 1.5mm

2

or AWG 16. Do not use clamping sleeves.

The strip length should be 10mm (0.40 inch). A too short a length might make the cable

loose, at too long, the result will be a piece of non-isolated cable.

The cable shields should be joined with a 1.0 mm2 isolated cable and then mounted to the

connector.

5.2 Connector placing

5.3 Connector J1, +24VDC, CAN-1

1,2

+24VDC

Power supply to the module

3,4

0VDC

Power ground

5,6

CAN1-H

CAN1-interface H-signal (use twisted pair cable for

CAN1-H and CAN1-L)

7,8

CAN1-L

CAN1-interface L-signal

9,10

CAN1-R

CAN1-interface termination pole (jumper between 9 and 10 for 120

termination)

11,12

0VDC

Signal ground

13

DI 1

Digital input 1

14

DI 2

Digital input 2

15

DI 3

Digital input 3

16

DI 4

Digital input 4

17

DI 5

Digital input 5

18

DI 6

Digital input 6

19

DI 7

Digital input 7

20

DI 8

Digital input 8

5.3.1 Inputs for the SSM function option

Use DI7 and DI8 as inputs for the Safeset supervision option.

J1/19

DI7

Connect to pulse sensor for the motor side.

J1/20

DI8

Connect to pulse sensor for the refiner side.

USB