4

1. The ends of the refrigerant lines must be cut square, de-

burred, cleaned, and be round and free from nicks or dents.

Any other condition increases the chance of a refrigerant

leak.

2. This unit is factory shipped with a holding charge. “Sweep”

the refrigerant line with nitrogen or inert gas during brazing

to prevent the formation of copper-oxide inside the refriger-

ant lines.

3. After brazing, quench the joints with water or a wet cloth to

prevent overheating of the service valve.

4. Ensure the filter drier paint finish is intact after brazing. If

the paint of the steel filter drier has been burned or chipped,

repaint or treat with a rust preventative. This is especially

important on suction line filter driers which are continually

wet when the unit is operating.

NOTE: Be careful not to kink or dent refrigerant lines. Kinked or

dented lines will cause poor performance or compressor damage.

Do NOT make final refrigerant line connection until plugs are

removed from refrigerant tubing.

NOTE: Before brazing, verify indoor piston size by checking the

piston kit chart packaged with indoor unit.

Leak Testing (Nitrogen or Nitrogen-Traced)

To avoid the risk of fire or explosion, never use oxygen, high

pressure air or flammable gases for leak testing of a refrigeration

system.

Pressure test the system using dry nitrogen and soapy water to

locate leaks. If you wish to use a leak detector, charge the system

to 10 psi using the appropriate refrigerant then use nitrogen to

finish charging the system to working pressure then apply the

detector to suspect areas. If leaks are found, repair them. After

repair, repeat the pressure test. If no leaks exist, proceed to sys-

tem evacuation.

System Evacuation

Condensing unit liquid and suction valves are closed to contain

the charge within the unit. The unit is shipped with the valve

stems closed and caps installed. Do not open valves until the

system is evacuated.

1. Connect the vacuum pump with 250 micron capability to the

service valves.

2. Evacuate the system to 250 microns or less using suction

and liquid service valves. Using both valves is necessary as

some compressors create a mechanical seal separating the

sides of the system.

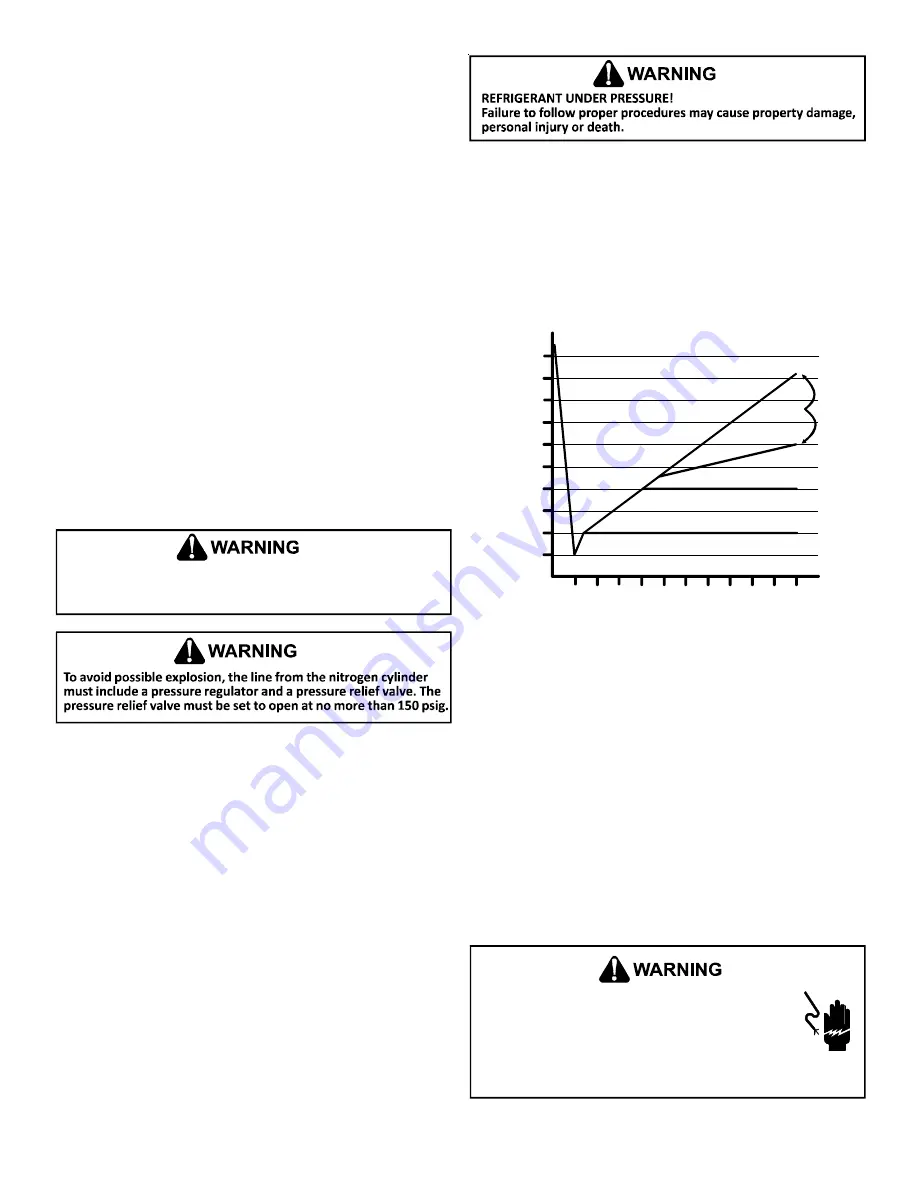

3. Close pump valve and hold vacuum for 10 minutes. Typi-

cally pressure will rise during this period.

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0 1 2 3 4 5 6 7 8 9

10

LEAK(S)

PRESENT

MINUTES

V

AC

U

U

M

IN

M

IC

RON

S

CONDENSIBLES OR SMALL

LEAK PRESENT

NO LEAKS

NO CONDENSIBLES

•

If the pressure rises to 1000 microns or less and remains

steady the system is considered leak-free; proceed to startup.

• If pressure rises above 1000 microns but holds steady be-

low 2000 microns, moisture and/or noncondensibles may

be present or the system may have a small leak. Return to

step 2: If the same result is encountered check for leaks as

previously indicated and repair as necessary then repeat

evacuation.

•

If pressure rises above 2000 microns, a leak is present. Check

for leaks as previously indicated and repair as necessary

then repeat evacuation.

Refer to the Remote Condensing Unit Service Manual for more

detailed instructions on system evacuation, preliminary charge

adjustment, and final charge adjustment.

Electrical Connections

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present. Failure to do

so may cause property damage, personal injury or

death due to electric shock. Wiring must conform with

NEC or CEC and all local codes. Undersized wires could cause

poor equipment performance, equipment damage or fire.