39

SYSTEM OPERATION

Gas Input (Natural Gas Only) Check

It is the responsibility of the contractor to adjust the gas

input to the unit.

To measure the gas input use a gas meter and proceed as

follows:

1. Turn off gas supply to all other appliances except the

unit.

2. With the unit operating, time the smallest dial on the

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds per

cubic foot of gas being delivered to the unit.

3. INPUT=GAS HTG VALUE x 3600 / SEC. PER CUBIC FOOT

Example:

Natural gas with a heating value of 1000 BTU per

cubic foot and 34 seconds per cubic foot as determined by

Step 2, then:

Input = 1000 x 3600 / 34 = 106,000 BTU per Hour.

NOTE: BTU content of the gas should be obtained from

the gas supplier. This measured input must not be greater

than shown on the unit rating plate.

Adjust input rate by varying the adjustment of the gas

pressure regulator on the gas valve. All adjustments

must be made with furnace operating at high fire and at

normal operating temperature. A manometer should be

connected to the gas valve to verify pressure is within

the specified range (see following figures for manometer

connections). Clockwise rotation of the pressure regulator

screw increases pressure and gas flow rate. Turn screw

counterclockwise to decrease pressure and gas flow rate.

After adjustment the furnace temperature rise must be

within the range specified on the unit data plate.

NOTE: Thermal efficiency of the furnace is a product

efficiency rating determined under continuous operating

conditions independent of any installed system.

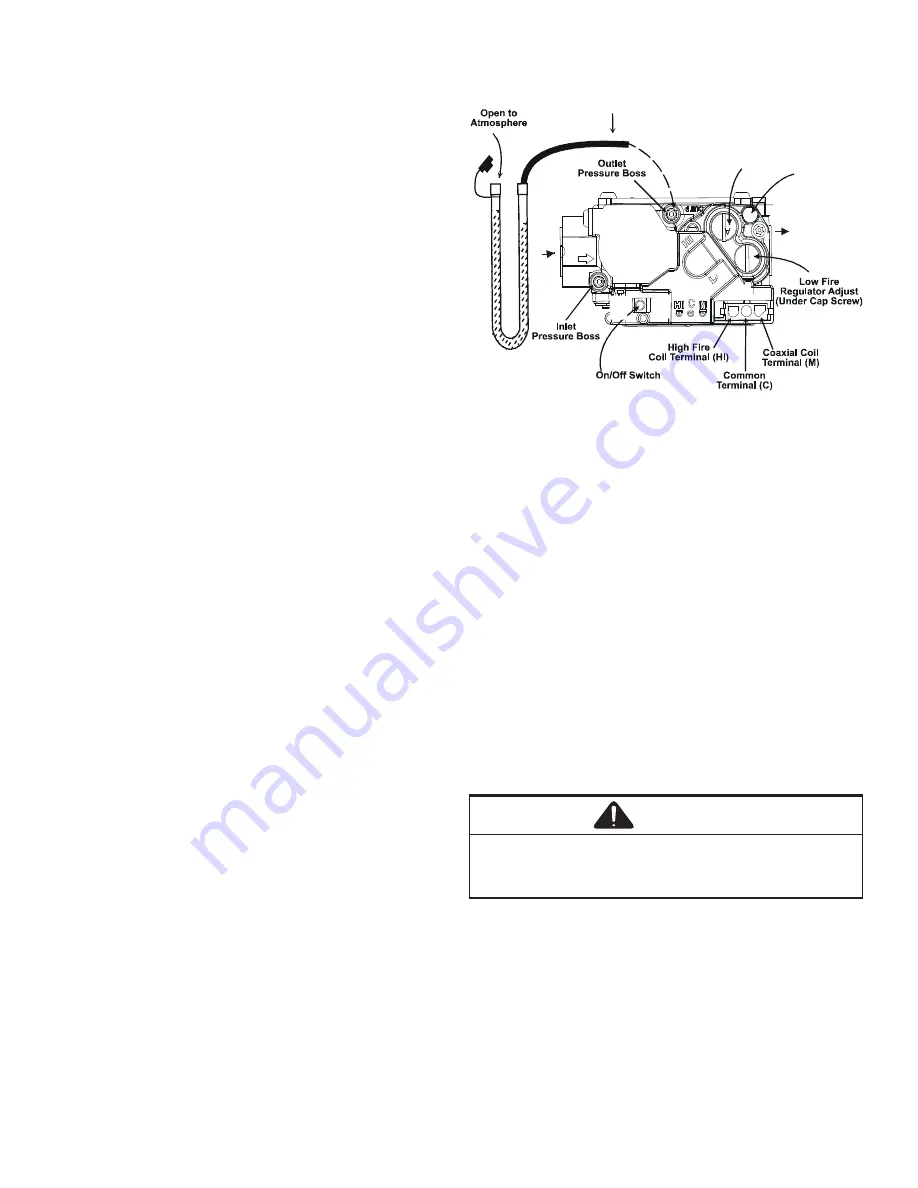

Manometer

Manometer

Hose

High Fire Regulator

Adjust

(Under Cap Screw) Regulator

Vent

Gas Flow

O

N

O

FF

white-rodgers (2-Stage) gas control valve connected

to manometer pressure adjustments

To connect manometer to gas valve:

1. Back outlet pressure tap screw (inside inlet pressure

boss) out one turn (counterclockwise, not more than

one turn).

2. Attach a hose and manometer to the outlet pressure

boss of the valve.

To remove manometer from gas valve:

1. Remove manometer hose from outlet pressure boss.

2. Turn outlet pressure tap screw in to seal pressure port

(clockwise, 7 in-lb. minimum).

3. Turn on electrical power and gas supply to the system.

4. Turn on system power and energize valve.

5. Using a leak detection solution or soap suds, check

for leaks at pressure boss screw. Bubbles forming

indicate a leak. SHUT OFF GAS AND FIX ALL LEAKS

IMMEDIATELY.

CAUTION

To prevent unreliable operation or equipment damage,

the gas manifold pressure must be as specified on the

unit rating plate. Only minor adjustments should be

made by adjusting the gas valve pressure regulator.

6. Relight all other appliances turned off in step 1 of gas

input check. Be sure all pilot burners are operating.

Main Burner Flame Check

Flames should be stable, soft and blue (dust may cause

orange tips but they must not be yellow) and extending

directly outward from the burner without curling, floating

or lifting off.

Содержание DRG0361DH00001S

Страница 20: ...20 SYSTEM OPERATION ...