11

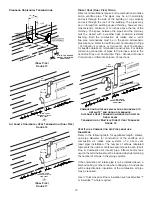

3. Locate 24” x ¼” tube in the bag assembly.

4. Install one end on front cover pressure switch.

5. Route tube to lower port on collector box cover and

cut off excess tubing.

Drain Trap and Lines

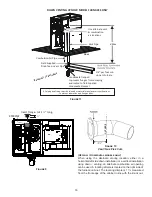

In horizontal applications the condensate drain trap is

secured to the furnace side panel, suspending it below the

furnace. A minimum clearance of 5.5” below the furnace must

be provided for the drain trap. Additionally, the appropriate

downward piping slope must be maintained from the drain

trap to the drain location. Refer to

Condensate Drain Trap

and Line

s for further details. If the drain trap and drain line

will be exposed to temperatures near or below freezing,

adequate measures must be taken to prevent condensate

from freezing.

Leveling

Leveling ensures proper condensate drainage from the heat

exchanger. For proper flue pipe drainage, the furnace must

be level lengthwise from end to end. The furnace should have

a slight tilt from back to front with the access doors downhill

from the back panel approximately ½ to 3/4 inches. The slight

tilt allows the heat exchanger condensate, generated in the

recuperator coil, to flow forward to the recuperator coil front

cover.

Alternate Electrical and Gas Line Connections

This furnace has provisions allowing for electrical and gas

line connections through either side panel. In horizontal

applications the connections can be made either through

the “top” or “bottom” of the furnace.

Drain Pan

A drain pan must be provided if the furnace is installed above

a conditioned area. The drain pan must cover the entire area

under the furnace (and air conditioning coil if applicable).

Freeze Protection

Refer to

Horizontal Applications and Conditions - Drain Trap

and Lines.

PROPANE GAS/HIGH ALTITUDE

INSTALLATIONS

WARNING

Possible Property damage, personal injury or death may

occur if the correct conversion kits are not installed. The

appropriate kits must be applied to ensure safe and proper

furnace operation. All conversions must be performed by a

qualified installer or service agency.

This furnace is shipped from the factory configured for

natural gas at standard altitude. Propane gas installations

require an orifice and spring change to compensate for the

energy content difference between natural and propane gas.

High

Stage

Low

Stage

Natural

None

#45

3.5" w.c.

1.9" w.c.

None

Propane

LPM-07*

1

1.25mm 10.0" w.c. 6.0" w.c.

None

Gas

Altitude

Kit

Orifice

Manifold Pressure

Pressure

Switch

Change

0-7000

1

LPM-07* supports both Honeywell and White-Rodgers 1-stage valves

NOTE:

In Canada, gas furnaces are only certified to 4500 feet.

For furnace being converted to LP gas, it is strongly

recommended that a LPLP03 kit also be installed. The use

of this kit will prevent the furnace from firing when the LP gas

supply pressure is too low to support proper combustion.

High altitude installations may require both a pressure switch

and an orifice/spring change. These changes are necessary

to compensate for the natural reduction in the density of

both the gas fuel and the combustion air at higher altitude.

For installations above 7000 feet, please refer to the furnace

Specification Sheets for required kit(s).

Contact the distributor for a tabular listing of appropriate

manufacturer’s kits for propane gas and/or high altitude

installations. The indicated kits must be used to insure

safe and proper furnace operation. All conversions must be

performed by a qualified installer, or service agency.

VENT/FLUE PIPE & COMBUSTION AIR PIPE

WARNING

Failure to follow these instructions can result in bodily

injury or death. Carefully read and follow all instructions

given in this section.

WARNING

Upon completion of the furnace installation, carefully

inspect the entire flue system both inside and outside of the

furnace to assure it is properly sealed. Leaks in the flue

system can result in serious personal injury or death due to

exposure to flue products, including carbon monoxide.

This manual will refer to the pipe that discharges products to

the outdoors as the “vent” pipe or “flue” pipe. The pipe that

supplies air for combustion to the furnace will be referred to

as the “intake” pipe or “combustion air” pipe. A condensing

gas furnace achieves its high level of efficiency by extracting

almost all of the heat from the products of combustion and

cooling them to the point where condensation takes place.

Because of the relatively low flue gas temperature and water

condensation requirements, PVC or ABS are typically used

as venting and intake pipe materials In Canada ABS is not

an approved vent pipe material, but it is permissible to use

as combustion air pipe material.

Содержание DC92SS

Страница 45: ...45 THIS PAGE IS LEFT INTENTIONALLY BLANK ...

Страница 46: ...46 THIS PAGE IS LEFT INTENTIONALLY BLANK ...

Страница 47: ...47 THIS PAGE IS LEFT INTENTIONALLY BLANK ...