4 Piping installation

Installation manual

8

EPRA14~W1

Daikin Altherma 3 H HT

4P586100-1 – 2019.07

1

1

2

3

3

1

1

2

3

4

3×

3.4

To remove the transportation stay

NOTICE

If the unit is operated with the transportation stay attached,

abnormal vibration or noise may be generated.

The transportation stays (2×) protect the unit during transport.

During installation they must be removed.

a

a

Transportation stays (2×)

1

Open the switch box cover. See

2

Remove the screws (4×) from the transportation stays.

3

Remove the transportation stays (2×), and dispose of them.

4

Reattach the screws to the unit.

4

Piping installation

4.1

Connecting the water piping

4.1.1

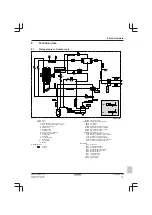

To connect the water piping

1

Connect the shut-off valve (with integrated filter) to the outdoor

unit water inlet, using thread sealant.

c

a

b

b

d

1

2

a

Water OUT (screw connection, male, 1")

b

Water IN (screw connection, male, 1")

c

Shut-off valve with integrated filter (delivered as accessory)

d

Thread sealant

2

Connect the field piping to the shut-off valve.

3

Connect the field piping to the outdoor unit water outlet.

NOTICE

About the shut-off valve with integrated filter (delivered as

accessory):

▪ The installation of the valve at the water inlet is

mandatory.

▪ Mind the flow direction of the valve.

NOTICE

Install air purge valves at all local high points.

4.1.2

To fill the water circuit

See the installation manual of the indoor unit, or the installer

reference guide.

4.1.3

To protect the water circuit against

freezing

About freeze protection

Frost can damage the system. To prevent the hydraulic components

from freezing, the software is equipped with special frost protection

functions such as water pipe freeze prevention and drain prevention

(see the installer reference guide) that include the activation of pump

in case of low temperatures.

However, in case of a power failure, these functions cannot

guarantee protection.

Do one of the following to protect the water circuit against freezing:

▪ Add glycol to the water. Glycol lowers the freezing point of the

water.

▪ Install freeze protection valves. Freeze protection valves drain the

water from the system before it can freeze.

NOTICE

If you add glycol to the water, do NOT install freeze

protection valves.

Possible consequence:

Glycol leaking

out of the freeze protection valves.

Freeze protection by glycol

Adding glycol to the water lowers the freezing point of the water.

The required concentration depends on the lowest expected outdoor

temperature, and on whether you want to protect the system from

bursting or from freezing. To prevent the system from freezing, more

glycol is required. Add glycol according to the table below.

INFORMATION

▪ Protection against bursting: the glycol will prevent the

piping from bursting, but NOT the liquid inside the

piping from freezing.

▪ Protection against freezing: the glycol will prevent the

liquid inside the piping from freezing.

Lowest expected

outdoor

temperature

Prevent from

bursting

Prevent from

freezing

–5°C

10%

15%

–10°C

15%

25%

–15°C

20%

35%

–20°C

25%

—

–25°C

30%

—