6

Warranty

We make every effort to assure that its products meet high

quality and durability standards, and warrants to the original

purchaser that this product is free from defects in materials

and workmanship for the period of one year from the date of

purchase. This warranty will not apply to damage due

directly or indirectly, to misuse, abuse, negligence or

accidents, repairs or alterations outside our facilities,

criminal activity, improper installation, normal wear and tear,

or to lack of maintenance.

We shall in no event be liable for

death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising from

the use of our product. Some states do not allow the

exclusion or limitation of incidental or consequential

damages, so the above limitation of exclusion may not apply

to you.

Custom Shop Customer Service contact: (619) 909-2110,

[email protected]

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY

AND FITNESS.

To take advantage of this warranty, the product or part must

be returned to us with transportation charges prepaid. Proof

of purchase date and an explanation of the complaint must

accompany the merchandise. The polisher's serial number

must also be intact. If our inspection verifies the defect, we

will either repair or replace the product at our election or we

may elect to refund the purchase price if we cannot readily

and quickly provide you with a replacement. We will return

repaired products at our expense. If we determine there is

no defect, or that the defect resulted from causes not within

the scope of our warranty, then you must bear the cost of

returning the product. This warranty gives you specific legal

rights and you may also have other rights which varies from

state to state.

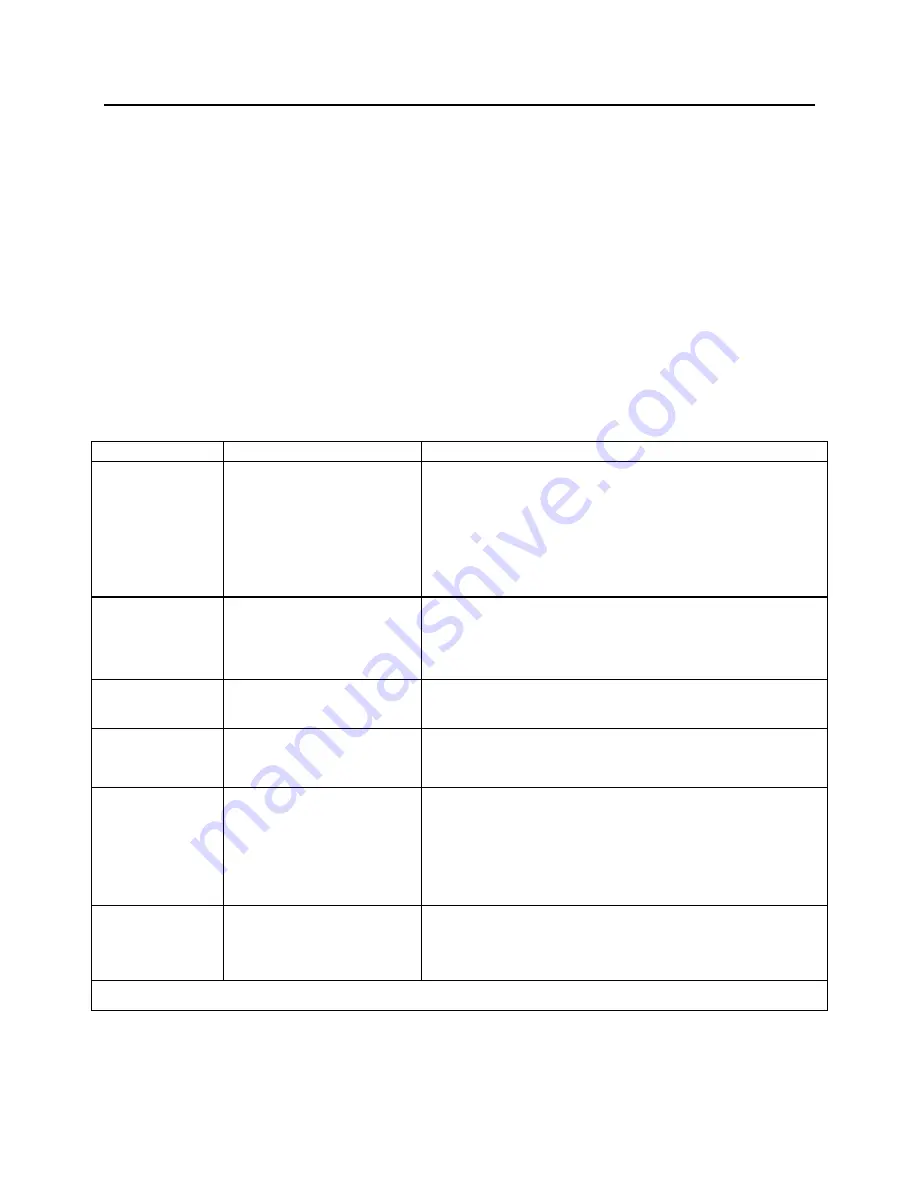

Troubleshooting

Problem

Possible Causes

Likely Solutions

Tool will not start.

1. Cord not connected.

2. No power at outlet.

3. Tool’s thermal reset breaker

tripped (if equipped).

4. Internal damage or wear.

(Carbon brushes or switch,

for example.)

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered, turn off tool and

check circuit breaker. If breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

3. Turn off tool and allow to cool. Press reset button on tool.

4. Have technician service tool.

Tool operates

slowly.

1. Excess pressure applied to

workpiece.

2. Power being reduced by

long or small diameter

extension cord.

1. Decrease pressure, allow tool to do the work.

2. Eliminate use of extension cord. If an extension cord is needed,

use one with the proper diameter for its length and load. See

Extension Cords

in

GROUNDING

section.

Performance

decreases over

time.

Carbon brushes worn or

damaged.

Have qualified technician replace brushes.

Excessive noise or

ratting

Internal damage or wear.

(Carbon brushes or bearings,

for example.)

Have technician service tool.

Overheating.

1. Forcing tool to work too fast.

2. Blocked motor housing

vents.

3. Motor being strained by long

or small diameter extension

cord.

1. Allow tool to work at its own rate.

2. Wear ANSI-approved safety goggles and NIOSH-approved dust

mask/respirator while blowing dust out of motor using compressed

air.

3. Eliminate use of extension cord. If an extension cord is needed,

use one with the proper diameter for its length and load. See

Extension Cords

in

GROUNDING

section.

Tool does not

sand or polish

effectively.

1. Accessory loose.

2. Accessory damaged, worn

or wrong type for the

material.

1. Confirm accessory arbor is correct and Outer Flange/Arbor Nut is

tight.

2. Check condition and type of disc accessory. Use only proper type

of disc accessory in good condition.

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.