ID

Part #

Description

Dimensions

Qty

11

010011

SS Nut

#8-32

8

53

050053

Black

1/2”

2

Plastic Cap

(1.3 cm)

77

050077

Black

3/8’

12

Plastic Cap

(0.9 cm)

120

010120

SS Machine

#8-32 x 2”

4

Screw

#8 x 5.1 cm)

123

010123

SS Machine

#8-32 x 1-1/2”

4

Screw

(#8 x 3.8 cm)

407

030407

Worm

5/8”

12

Clamp

(1.6 cm)

409

030409

Worm

11/16”

14

Clamp

(1.7 cm)

410

030410

Worm

1”

18

Clamp

(2.5 cm)

411

030411

Worm

1-1/8”

6

Clamp

(2.9 cm)

412

030412

Worm

1-1/2”

6

Clamp

(3.8 cm)

565

124565

Fiberglass

5/8” x8”

2

Insulator

(1.6 x 20.3 cm)

566

124566

Fiberglass

7/8” x 8”

1

Insulator

(2.2. x 20.3 cm)

567

124567

Fiberglass

1” x 8”

1

Insulator

(2.5 x 20.3)

941

011941

SS Lock

#8

8

Washer

EA

X79EA

Aluminum

1-1/4” x 72”

1

Tube

(3.2 x 183 cm)

EB

X79EB

Aluminum

1-5/8” x 52”

4

Tube

(2.8 x 132 cm)

EC

E79EC

Aluminum

1” x 36”

4

Tube

2.5 x 91 cm)

ED

X79ED

Aluminum

3/4” x 36”

8

Tube

(1.9 x 91 cm)

EE

X79EE

Aluminum

1/2” x 36”

6

Tube

(1.3 x 91 cm)

EF

E79EF

Aluminum

3/8” x 48”

4

Tube

(1.0 x 122 cm)

EG

E79EG

Aluminum

1” x 48”

1

Tube

(2.5 x 122 cm)

EH

E79EH

Aluminum

7/8” x 48”

2

Tube

(2.2 x 122 cm)

EJ

E79EJ

Aluminum

3/8” x 32”

4

Tube

(1.0 x 81 cm)

EK

X79EK

Aluminum

1” x 24”

2

Tube

(2.5 x 61 cm)

EL

X79EL

Aluminum

1-1/4” x 36”

2

Tube

(3.2 x 91 cm)

EM

X79EM

Aluminum

1/2” x 24”

6

Tube

(1.3 x 61 cm)

EN

X79EN

Aluminum

3/8” x 36”

4

Tube

(1.0 x 99 cm)

EP

X79EP

Aluminum

1-1/4” x 48”

1

Tube

(3.2 x 122 cm)

ER

X79ER

Aluminum

1-1/8” x 48”

2

Tube

(2.9 x 122 cm)

ES

X79ES

Aluminum

1/2” x 36”

2

Tube

(1.3 x 91 cm)

ET

X79ET

Aluminum

7/8” x 36”

2

Tube

(2.2 x 91 cm)

EU

X79EU

Aluminum

3/4” x 36”

4

Tube

(1.9 x 91 cm)

EV

X79EV

Aluminum

1” x 36”

2

Tube

(2.5 x 91 cm)

EY A34SEF

Aluminim

1” x 5-1/4”

2

Tube

(2.5 x 13.3 cm)

6

5

4”

(10.16 cm)

1/4”

(.63 cm)

565

941

11

123

941

11

123

Figure 5C

566

941

11

120

941

11

120

Figure 5B

See Fig. 5D

See Fig. 5D

See Fig. 5C

FIGURE 5

ER

ER

EP

EV

ES

TB

T9

EY

EJ

EM

EU

EF

EE

EU

ED

ET

EK

EC

EN

EM

EN

ED

EE

EB

EL

ED

EM

EJ

EH

EG

ED

EE

EF

EC

EB

EA

ED

EE

EF

EC

EB

ED

EM

EJ

EH

EC

EN

ED

EE

EB

EL

ED

ET

EK

EN

EM

EF

EE

EU

EJ

EM

EU

EV

ES

TB

T9

EY

See Fig. 5B

86”

(218.4 CM)

7”

(17.8 CM)

24”

(60 CM)

111”

(291.9 CM)

137”

(348 CM)

208”

(528.3 CM)

147-1/2”

(374.6 CM)

220”

(558.8 CM)

220”

(558.8 CM)

147-1/2”

(374.6 CM)

208”

(528.3 CM)

137”

(348 CM)

111”

(291.9 CM)

86”

(218.4 CM)

7”

(17.8 CM)

407

409

410

411

412

410

410

407

409

410

411

412

407

409

410

407

409

410

407

409

407

409

411

412

410

410

410

409

410

410

407

409

410

411

412

410

411

412

407

409

410

407

409

410

407

409

407

411

412

410

409

410

410

407

409

409

567

566

565

565

CL

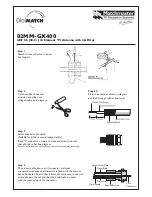

Figures 5, 5A, 5B, and 5C show the steps for element assembly. Identify the tubing sections required for each element

using the Element Subassembly Parts List.

Each telescoping tubing section is inserted 4 inches into the larger section except where noted in Figure 5. Adjust the

length of the end tubing section to give each element the proper total half length. All dimensions should be within 1/4 inch

of the values given. Mark the center of tubing sections EA, EG, and EP with a marker as shown in Figure 6A. These

marks will be used in Step 4 when elements are mounted on the boom. The dimension for tube ES is measured from

the end of trap TB. The dimension between traps TB and T9 is measured between the ends of each trap. The 77 inch

dimension from element #7 center is measured to the end of trap T9. Insure all traps are installed with arrows pointing

toward the boom. Also position trap drain holes so they will be facing the ground when the antenna is in its final position.

Unless indicated otherwise, telescope

elements 4” (10.16 cm) and tighten

the worm clamp.

IMPORTANT

77

77

77

77

77

77

53

CL

ER

EP

ER

Butt ends of ER’s together

at the center of EP

24”(61cm)

53

77

77

77

77

77

77

3-Element Assembly

567

941

11

120

941

11

120

Figure 5A

Install all worm clamps as shown. Tighten all worm clamps until the telescoped tubing cannot rotate

inside the larger tube. Take care not to overtighten and strip the worm clamp. Extra worm clamps are provided.

Note that all element sections can be fastened using a self-taping screw at each tubing transition. Use

stainless screws for best performance. Properly installed worm clamps will provide years of trouble free

service.

The X7 is constructed entirely with .058-inch wall tubing. This creates a tight transition with the closest

possible fit and better ice-loading characteristics than antennas constructed with thinner wall tubing.

Elements 3, 4, 5 and 6 have fiberglass center sections. Reference figures 5A, 5B and 5C for proper assembly.

After mounting element end caps (53, 77) punch a small hole (1/4”) in the bottom edge (ground facing side)

of the cap for water drainage.

Element #1

Element #2

Element #3

Element #4

Element #5

Element #6

Element #7

77”

(195.6 CM)

35”

(88.0 CM)

77”

(195.6 CM)

35”

(88.0 CM)

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

Final Length

Adjustment

8” (20.3 CM)

Insert

8” (20.3 CM)

Insert