4

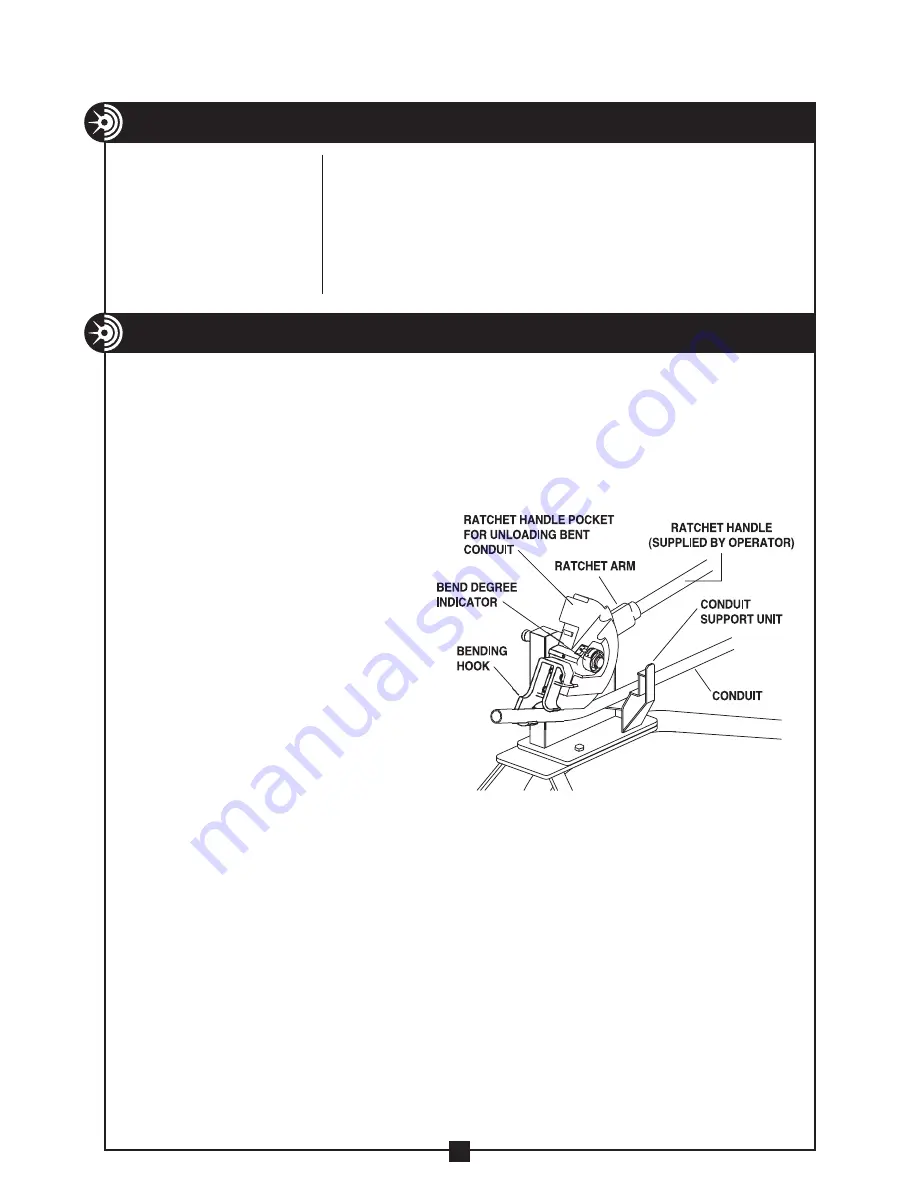

Figure 1

SPECIFICATIONS

Model No.

750

Capacity

½

" to 1" RIGID and IMC conduit and

schedule 40 pipe

Overall Dimensions

48" L x 24

½

" W x 30" H

Weight

91 lbs.

OPERATING INSTRUCTIONS

1. Cut a 5' length of 1" RIGID conduit and insert it into the ratchet arm as

shown in Figure 1. This will serve as the ratchet handle.

2. Place the ratchet handle in the up position. This will release the ratchet pawl.

Rotate the bending shoe counter-clockwise. Then lower the ratchet handle.

3. Slide the conduit to be bent

over the corresponding size

on the conduit support unit,

through the shoe groove and

bending hook.

4. Place the bending mark on the

conduit in line with the front

edge of the bending hook.

See Figure C on page 6.

5. Raise the ratchet handle until

the pawl clicks. Push the ratchet

handle down. Repeat until you

have completed the desired bend.

6. To remove bent conduit, raise the ratchet handle to the up position.

Remove the ratchet handle from the ratchet arm and slide it into the pocket

provided on the bending shoe. While holding the bent conduit, slowly

rotate the bending shoe in the counter-clockwise direction and remove

the bent conduit.

7. Place the ratchet handle back into the ratchet arm and lower the ratchet

handle to the down position.

NOTE:

Springback compensation is not calculated on the

bending degree indicator.

NOTE:

When not in use the ratchet handle MUST remain in

the down position.