5) Turn the feedwater tapping valve handle clockwise to close

the valve. With a wrench, tighten the nut/seal around the

valve handle stem.

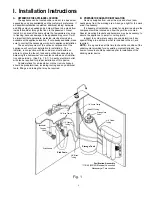

6) Remove the cover from the appliance and disconnect the

orange 1/4" tubing from the feedwater fitting. (See Fig. 6)

7) Connect one end of the orange tubing to the feedwater

tapping valve using the brass compression nut, insert, and

plastic sleeve. (See Fig. 3)

NOTE:

For basement installations, the existing orange feed-

water tubing may have to be longer to reach the feedwater tap-

ping valve.

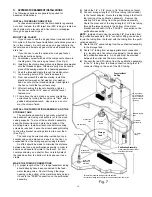

G. PREFILL AND SANITIZE THE STORAGE TANK

Prefilling the storage tank is always recommended so that

there is pressure to check for leaks as well as sufficient water

to flush the carbon postfilter. The SQC RO Drinking Water

Appliance is furnished with a container of special sanitizing

granules. It is important to use a sanitizer when prefilling the

tank.

1) Thread the taped 3/8" x 1/4" tank fitting into the tank valve.

Do not over tighten. Open the tank valve so that the tank

handle is parallel to the valve body. Locate the enclosed

container of sanitizing granules, open it and pour the

contents into the end of the tank valve.

2)

Disconnect the 3/8" yellow tubing from the back of the

purification assembly and connect one end of it into the tube

fitting located on the tank valve.

3) Connect the other end of the 3/8" yellow tubing to the 3/8"

x 1/4" union connector included in the tank sanitization kit.

4) Connect the free end of the 1/4" orange feed water tubing

to the other end of the 3/8" x 1/4" union connector.

5)

Open the feedwater tapping valve (making sure the tank

valve is still open) and allow the tank to fill (about 3 minutes).

6) Close the feedwater tapping valve and the tank valve.

Disconnect the 3/8" yellow tubing from the tank valve

elbow fitting and set the tank aside while proceeding with

the rest of the installation (the sanitizing solution should be

kept in the tank for at least 15 minutes).

NOTE:

If you encounter difficulty in removing the tubing from

the tank, make sure the tank valve is closed and then cut the

yellow tubing approximately 1" away from the tank valve fitting to

relieve the pressure. Remove the 1" piece from the tank fitting.

NOTE:

If an alternate storage tank is used, it should be sani-

tized with household bleach (5-1/4%). Use 3 ml. (1/2 tea-

spoon) of bleach for a 2.5 gallon tank.

7) Reconnect the 3/8" yellow tubing to the back of the

purification assembly. Reconnect the 1/4" orange tubing to

the feedwater fitting on the purification assembly.

IMPORTANT:

After the installation is complete, it is recom-

mended that the 3/8" x 1/4" union connector be saved for

future use in tank sanitization.

H. INSTALL THE DRAIN CONNECTION

IMPORTANT:

Before starting this procedure, inspect the con-

dition of the drain piping, especially in older homes where the

traps and tailpieces can be deceptively thin and frail. If they

are in poor condition, it is wise to inform the customer that the

condition should be remedied.

IMPORTANT: Some local plumbing codes may prohibit

the use of saddle-type valves and/or drain connections.

The use of saddle-type valves are prohibited in Alaska,

Delaware, Idaho, Kentucky, Massachusetts, Michigan,

Minnesota, New Hampshire, North Dakota, Ohio, and

South Dakota. Check your local plumbing codes for any

restrictions that apply. Massachusetts CMR 248 strictly

prohibits the use of saddle-type valves. The feedwater

connection must conform to applicable plumbing codes.

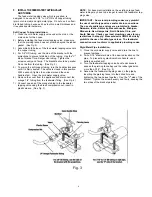

Undercounter Installation:

The drain saddle assembly is designed to fit around a

standard 1-1/2" OD drain pipe. For smaller (lavatory type) or

larger (ABS pipe) drains, consult your dealer for special drain

saddles.

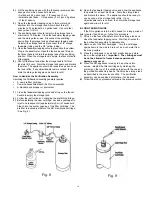

The drain saddle should always be installed above (before)

the trap and on the vertical or horizontal tailpiece. Never install

the drain saddle close to the outlet of a garbage disposal

because plugging of the RO drain line may occur. (See Fig. 4)

1)

Position the threaded half of the drain saddle at the selected

location and mark the pipe through the threaded opening.

2)

Drill a 1/4" hole at the marked location through one side of

the drain tailpiece.

3)

Position both halves of the drain saddle on the drain pipe

so that the threaded opening is lined up with the hole in

the drain pipe.

4)

Use the screws and nuts to clamp the drain saddle onto

the drain pipe. Make sure that there is equal space

between saddle halves on each side. Do not overtighten.

(See Fig. 5)

5)

Orient the elbow in the direction of the RO faucet location.

Fig. 4

7

Содержание SQC Pro

Страница 15: ...Appendix 1 Electrical Diagram 15 ...