14

5

Making

Adjustments

WARNING

Read, understand, and

follow all instructions

and warnings on the

machine and in this

manual before operat-

ing.

Never attempt to

make any adjustments

while the engine is

running, except where

specified in operator’s

manual.

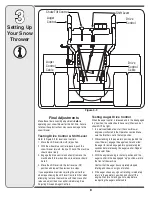

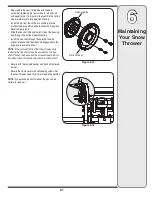

Shift Rod

If the full range of speeds (forward and reverse) cannot

be achieved, refer to the figure to the left and adjust the

shift rod as follows:

1. Looking underneath the handle panel, note which

of the three holes in the shift lever the ferrule is

inserted into. Also note the direction of insertion.

Then remove the internal cotter pin and flat washer

from the ferrule and withdraw the ferrule from the

shift lever. See Figure 5-1.

2. Place shift lever in sixth (6) position or fastest

forward speed.

3. Push shift rod and shift arm assembly down sharply

as far as it will go to put the drive into the fastest

forward position.

4. As necessary, rotate the ferrule up or down the shift

rod until the ferrule lines up with the hole from which it

was earlier removed. See Figure 5-1.

5. From the direction noted earlier, insert the ferrule into

the proper hole.

6. Reinstall the washer and the internal cotter pin.

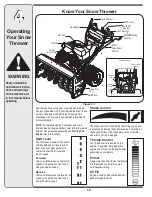

Chute Control

The distance snow is thrown can be adjusted by adjusting

the angle of the chute assembly. Refer to “Operating Your

Snow Thrower” for instructions.

The remote chute control cables have been pre-adjusted

at the factory. Move the remote chute lever on the control

panel back and forward to adjust angle of the chute

assembly.

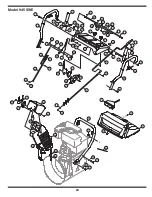

Drive Control

Refer to the Final Adjustment section of the Assembly

instructions to adjust the drive control. To further check

the adjustment, proceed as follows:

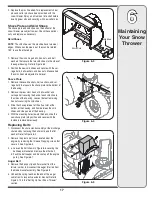

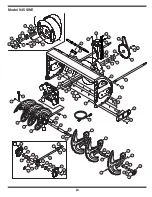

1. With the snow thrower tipped forward (be certain to

drain gasoline or place plastic film under the gas cap if

the snow thrower has already been operated), remove

the frame cover underneath the snow thrower by

removing the self-tapping screws. See Figure 5-2.

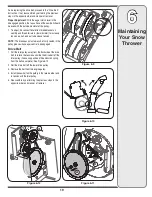

2. Locate the opening between the axle support bracket

and the front frame support (See Figure 5-3). Looking

through this opening, with the drive control released,

there must be 1/8” clearance between the friction

wheel and the drive plate in all positions of the shift

lever.

3. With the drive control engaged, the friction wheel must

contact the drive plate. See Figure 5-3.

Figure 5-1

Figure 5-