7

SECTION 3: KNOW YOUR LOG SPLITTER

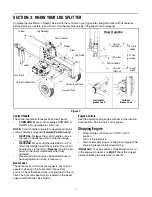

Compare the illustration in Figure 7 below with the controls on your log splitter, and get familiar with its features

before starting to operate. Know how to stop the machine quickly in the event of an emergency.

Figure 7

Control Handle

The control handle has three positions. See Figure 7.

•

FORWARD:

Move control handle FORWARD or

DOWN to move wedge to split wood.

NOTE:

Control handle will return to neutral position as

soon as handle is released.(

Forward Position only

)

•

NEUTRAL:

Release the control handle or move

the lever to neutral position to stop the wedge

movement.

•

REVERSE:

Move control handle BACK or UP to

return the wedge toward the cylinder. The control

handle stays in the return (

Reverse

) position and

returns to neutral automatically when fully

retracted.

•

Reverse position may also be operated back to

neutral position manually, if necessary.

Beam Locks

These two locks, as their name suggests, are used to

secure the beam in the horizontal or the vertical

position. The vertical beam lock is located next to the oil

filter. The horizontal beam lock is located on the beam

support latch bracket. See Figure 7.

Engine Controls

See the accompanying engine manual for the location

and function of the controls on the engine.

Stopping Engine

•

Move throttle control lever to STOP or OFF

position.

•

Turn off the fuel valve.

•

Disconnect spark plug wire and ground against the

engine to prevent unintended starting.

IMPORTANT:

Your log splitter is shipped with motor oil

in the engine. However, you

MUST

check the oil level

before operating. Be careful not to overfill.

Horizontal

Control Handle

Reservoir Tank

Vertical Beam Lock

Jack Stand

Beam

Wedge

Cylinder

Log Cradle

Beam Lock

Vertical

Beam Lock

Tongue

Horizontal Beam Lock

How it works

Log Dislodger

Control Handle

To stop

Forward

Neutral

Reverse

(Automatic)

(Manual)

wood

To split

To return

wedge

wedge