36

3.

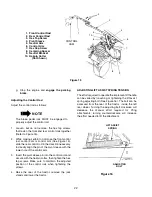

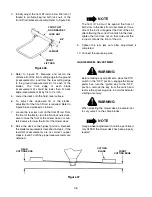

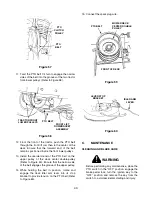

Initially adjust the front lift rod to allow 5/8 inch of

thread to protrude beyond both lock nuts of the

front lift rod/bracket assembly (Refer to Figure 36).

Figure 36

4.

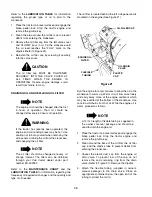

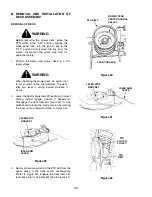

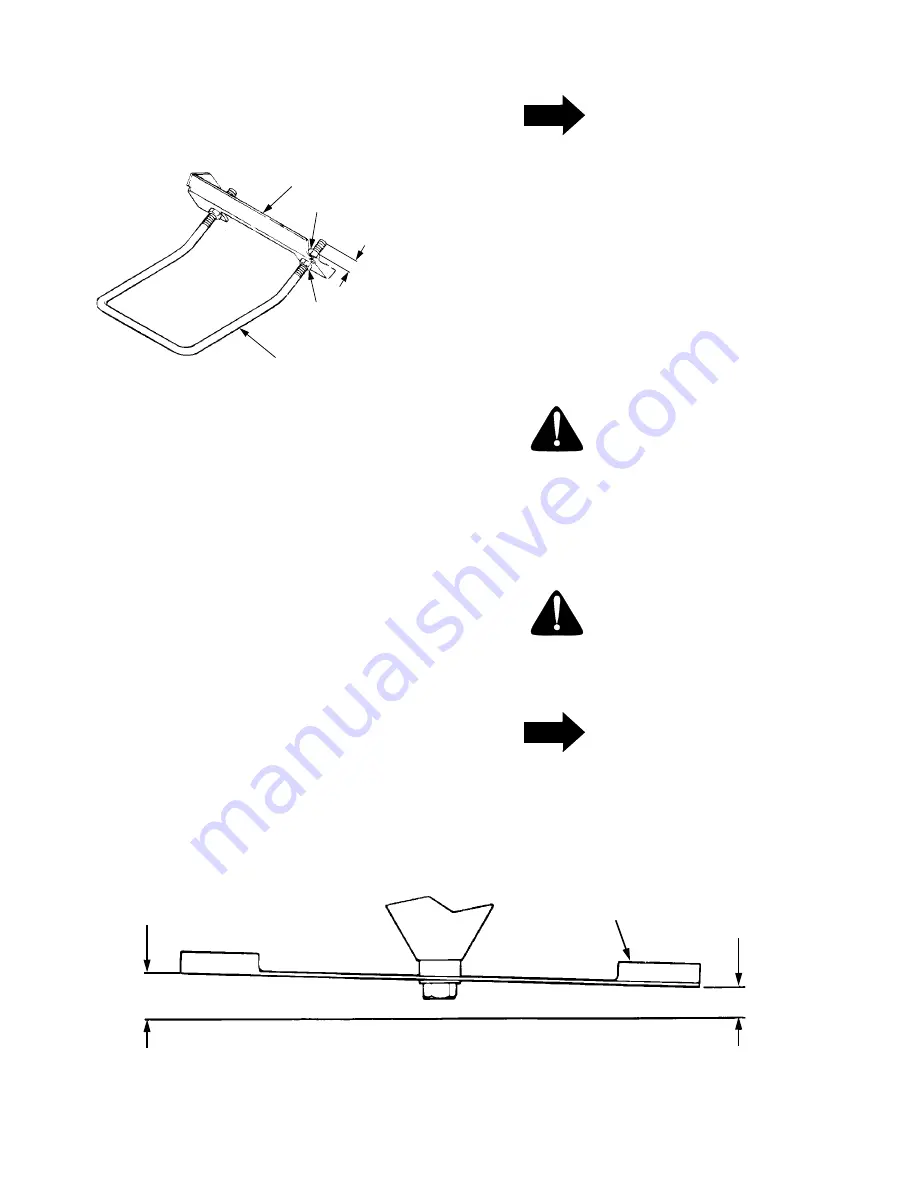

Refer to Figure 37. Measure and record the

distance from the front cutting edge to the ground

(measurement A), and from the rear cutting edge

to the ground (measurement B), for each of the

blades. The front edge of each blade

(measurement A) should be lower than its back

edge (measurement B) by 1/8 to 1/4 inch.

5.

Lower the deck onto the hard, level surface.

6.

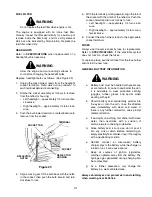

To adjust the downward tilt of the blades,

adjustment of the front lift rod is required. Refer to

Figure 36 and proceed as follows:

7.

Loosen the rear jam nuts on the front lift rod. From

the front of the tractor, turn the front lock nuts clock-

wise to raise the front of the mower deck, or coun-

terclockwise to lower the front of the mower deck.

8.

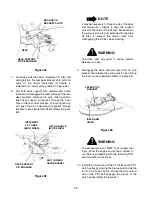

Raise the deck to the highest position. Recheck

the blade measurements described in step 4. If the

resultant measurements are not correct, repeat

steps 5, 6 and 7 until the proper measurements are

obtained.

NOTE

The front lift rod must be against the front of

both slots in the deck front roller bracket. If one

side of the rod is not against the front of the slot

after attaining the correct front pitch to the deck,

tighten the front lock nut on that side until the

rod just contacts the front of the slot.

9.

Tighten the rear jam nuts after adjustment is

completed.

10. Connect the spark plug wire.

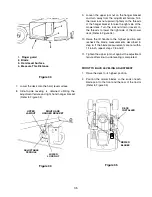

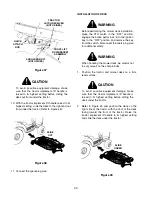

GAUGE WHEEL ADJUSTMENT

WARNING

Before making any adjustments, place the PTO

switch in the “OFF” position, engage the brake

pedal lock, turn the ignition key to the “OFF”

position, remove the key from the switch and

remove the spark plug wire to avoid accidental

starting and injury.

WARNING

When adjusting the mower deck, be careful not

to cut yourself on the sharp blades.

NOTE

Gauge wheel adjustment should be performed

only AFTER the mower deck has been properly

leveled.

FRONT

LIFT ROD

JAM NUT

LOCK NUT

FRONT LIFT

ROD BRACKET

5/8"

Figure 37

REAR

CUTTING EDGE

FORNT

CUTTING EDGE

CUTTING

BLADE