nVision

Operation Manual

•

Page 29

The following steps must be performed sequentially to properly complete the module change:

1

Before removing or replacing any modules, ensure that all recorded data has

been archived properly through the use of

Export Data

in

CrystalControl.

2

Place nVision on clean stable work surface.

Clean exterior of the product, if necessary, to ensure

no moisture or foreign matter will enter the enclosure when disassembled.

Use of proper ESD

grounding techniques is highly encouraged to prevent damage to the exposed module.

3

nVision Reference Recorder;

Turn off nVision with the

(power) button, then remove the 4AA

battery pack from the rear of the unit.

nVision Lab Reference;

Turn off nVision with the

(power) button, then disconnect the power

cord from the AC power source.

4

Remove any USB power connnection from the nVision chassis during module installation.

WARNING:

Failure to disconnect nVision from 4AA, USB or AC power before module re-

moval installation may cause damage.

5

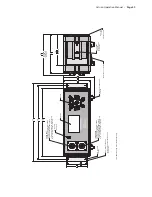

Using a Torx T10 wrench, loosen the four screws retaining the module face plate and carefully

pull the module out.

Avoid twisting the module when removing from the nVision.

Note:

Some modules may be difficult to remove due the physical form and the IP67 sealing

strategy employed.

It may be necessary to connect a fitting or RTD cable to the appropriate

module in order to gain better gripping power for removal.

Never force the separation of a

module from an nVision chassis.

6

Note the correct orientation of module connector on rear of module (located up or closest

toward the display) in relation to the nVision chassis during removal. Place the removed nVision

module in the ESD bag for safe protection.

7

Install new module in similar orientation as one removed in step 2 (rear module connector

facing up to keypad of nVision).

If improperly oriented the tri-lobe design of the module will not

allow proper installation.

Do not force installation of the module as permanent damage may

occur. Ensure light lubrication of the module’s unique quad-lobe o-ring (P/N: 4110) with Dow 111

silicon lubricant or equivalent to ensure an IP67 rated seal.

Note:

If installing blank plate, instead of module, ensure part is oriented flat and evenly within

the module bay for proper sealing.

8

Tighten face plate or blank plate screws to

50 in-oz (0.35 newton meter (N-m)) torque (T10 Torx)

.

9

Replace 4AA power module and tighten adequately to ensure IP67 seal.

When power is first

applied by the battery pack, the unit will automatically turn on.

Ensure that nVision recognizes

the new module by confirming in

CrystalControl or the Summary screens.

10

Before using the nVision to record,

Erase All Data

using

setup

button

Recording/Erase All Runs

menu items.

11

nVision is now ready to use.

If you have any problems during this process, check the

Troubleshooting section for relevant information or contact Crystal Engineering at

or (805) 595-5477.

Содержание nVision Lab Reference Recorder

Страница 1: ...C R Y S T A L engineering corporation Operation Manual Reference Recorder Lab Reference ...

Страница 6: ......

Страница 67: ......