20

21

18/09/2016

LP-OMLINK-B

The pump will draw liquid from the tank and bypass

this until such time as you open the manual taps and

flick the main lever on the manual control unit to the

open position. Refer to the section below AR UCM

controller operation.

Once the boom taps and master on/off lever on

the manual control unit are in the open position,

the nozzles should spray. Using the rotary pressure

relief valve knob, you can now adjust the pressure

to the recommended spraying pressure by rotating

the PRV knob. Anti-clockwise rotation will reduce

the pressure; clockwise rotation will increase the

pressure. Using the pressure gauge on the control

unit, you can determine the spraying pressure. For

most boom-spraying jobs, a pressure between 1

and 5 bar (30 to 70 psi) is the norm. The AirMix™

low-drift nozzles can be safely operated within a

1-6 bar pressure range, but note that the Spray

Quality will be influenced by your spraying pressure.

For more information on Spray Quality, you can

access the Croplands Buyers Guide on line

and check the chart for AirMix™ nozzles – this

information is in the nozzle section.

Most chemical labels advise the application

rate and spray quality for the product being

used. Youmay wish to discuss this with your local

agronomist if you are unsure.

If you have electric controls or an Auto-Rate spray

controller fitted to you AgriPak linkage sprayer,

please refer to the Croplands manual relevant to the

model you have purchased to learn how to use this

prior to start up. Croplands Technical support can

also be contacted should you need assistance (see

back page for contact details)

Flushing tank – standard on 300, 600 and

800 litre models

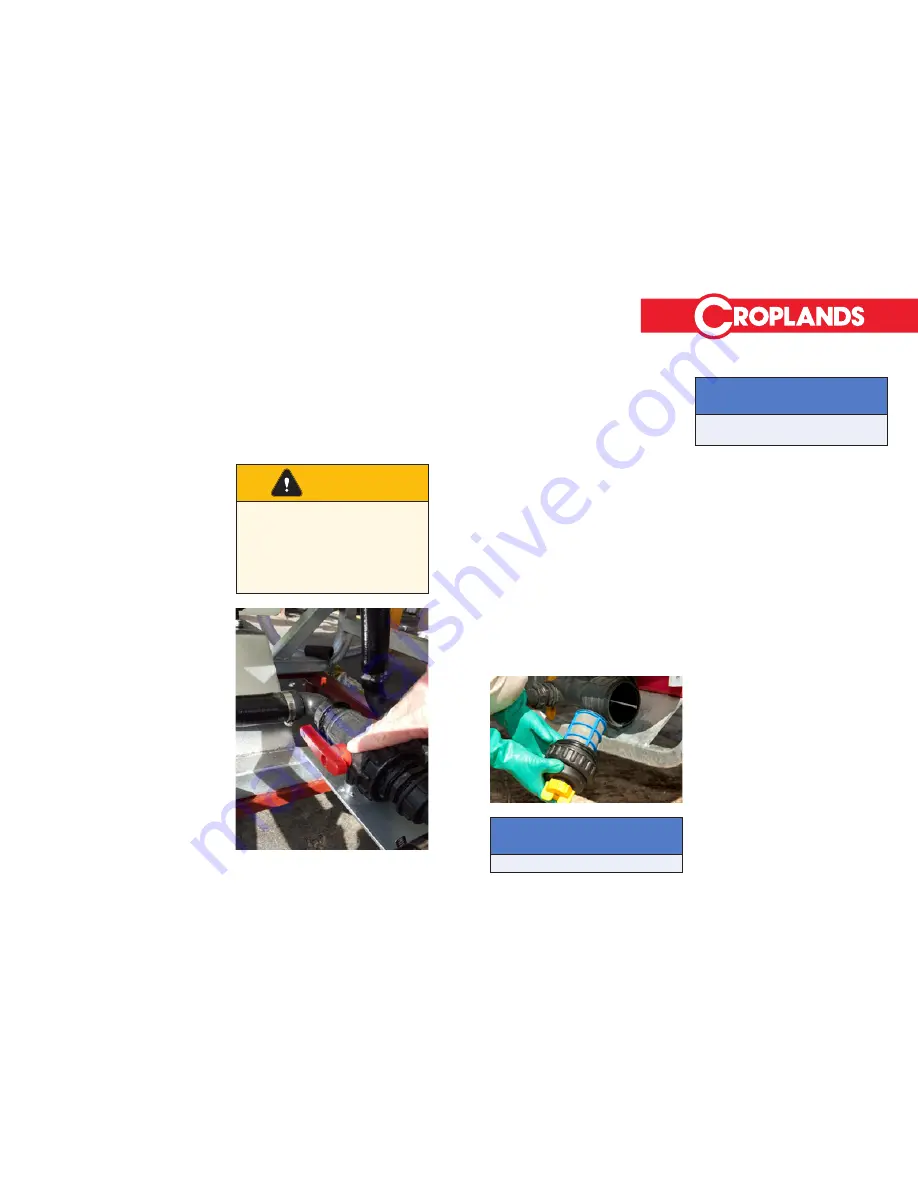

A 3-way ball valve is provided on the suction line to

allow the operator to select suction from either the

main spray tank, or the fresh-water flushing tank.

CAUTION

Never use the fresh water flushing or

handwash tank for chemical use. These

tanks are designed specifically for

holding fresh water for either flushing the

sprayer, or in the case of the hand-wash

tank, for the operator to use for cleaning

hands or the suction filter in the field.

To flush the sprayer in the field after spraying, shut

off the boom using the liquid controls, stop the PTO

and leave the boom in the unfolded operating

position. Using the ball valve, select the fresh water

flush tank. Climb back into the tractor cab, start the

PTO and open the manual or electric control to

allow fresh water to flow through the spraying circuit

and the nozzles. If you have remaining spray left in

the main tank, flush only for one to two minutes to

flush the pump and boom lines.

If you have finished your spraying job and the

main tank is empty, you can flush the system for 5

minutes, or until the flushing tank is empty, to ensure

the system is thoroughly flushed with fresh water. It

is recommended to do this in the field so that any

chemical residue is deposited in the area you have

been spraying to avoid continual deposits back at

the spray shed site.

A thorough tank clean once back at the shed is

recommended if you have finished your spray

job. Always drain the main tank when finished. To

avoid algae build up in the fresh water tanks, it is

recommended these also be drained and refilled

just prior to the next spraying job.

This will ensure your AgriPak sprayer is ready to go

prior to its next use. To clean the filters:

»

Ensure the shut-off tap is in the “off” position, or

the shut off plug is removed from the filter housing

»

Remove the filter element from the housing by

undoing the main filter housing nut

»

Clean the filter element with fresh water (note,

if the suction filter does become blocked during

spraying, this can be cleaned in the field by using

the handwash tank

»

If a pressure filter is fitted (normally if the sprayer

has electric controls fitted), also remove the filter

cartridge and clean with fresh water

»

Inspect the nozzle filters, at least one from each

boom section, and if required, clean these in fresh

water. The nozzles filters are up inside the nozzle

body and can be accessed by removing the

nozzle cap. If care has been taken to have clean

water used for spraying, and the suction filter is

kept clean, the nozzle filters should not block.

After and extended time of non-use, it is

recommended you check the filters before your next

spray job. Often spiders or wasps can get into the

filter housing.

NOTE

Always use gloves when handling filters.

NOTE

Always clean the filters when your

spraying job is completed.