2

Thank you very much for purchasing a CROMMELINS™ COMPACTOR.

This manual covers the operation and maintenance of the your compactor. These models

are built to industry best standards, for use in mining, construction, hire industries and

general use.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at any time.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

Please fill in the following blanks after checking the production number and serial

number on your product. (The location of these numbers may vary).

CONTENTS

Introduction & contents ......................................................................................

2

Warranty ...............................................................................................................

3

Safety ....................................................................................................................

4

Pre-operation checkup .........................................................................................

5

Starting your compactor …..……………………………………….........................................

5

Hints of operation .................................................................................................

6

Stopping your compactor …….................................................................................

6

Maintenance, belt setting & storage ..................................................................

7

Specifications charts ..........................................................................................

8

Trouble shooting .................................................................................................

9

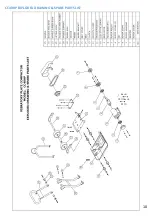

CC40HP Exploded drawing & parts list ..................................................................

10

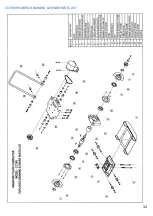

CC60 Exploded drawing & parts list .......................................................................

11

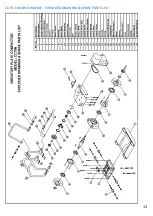

CC70 Exploded drawing & parts list .......................................................................

12

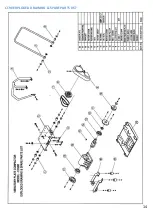

CC70 Folding handle exploded drawing & parts list ..............................................

13

CC90 Exploded drawing & parts list ......................................................................

14

SERIAL NO.

MODEL NO.

Содержание CC40HP

Страница 10: ...10 CC40HP EXPLODED DRAWING SPARE PARTS LIST...

Страница 11: ...11 CC60 EXPLODED DRAWING SPARE PARTS LIST...

Страница 12: ...12 CC70 EXPLODED DRAWING SPARE PARTS LIST...

Страница 13: ...13 CC70 FOLDING HANDLE EXPLODED DRAWING SPARE PARTS LIST...

Страница 14: ...14 CC90 EXPLODED DRAWING SPARE PARTS LIST...

Страница 15: ...15...