7

In the event of an overtemperature, the source of this

condition should be determined and rectifi ed immediately.

Thermal protection shall not be used as a motor overload

device. A separate motor overload device must be provided

in accordance with NEC codes.

DO NOT LET THE

PUMP CYCLE OR RUN IF AN OVERLOAD CONDITION

OCCURS!

Moisture Sensors: (Optional) -

A normally open (N/O)

detector is installed in the pump seal chamber which will

detect any moisture present. It is recommended that this

detector be connected in series to an alarm device or the

motor starter coil to alert the operator that a moisture detect

has occurred. In the event of a moisture detect, check the

individual moisture sensor probe leads for continuity, (∞

resistance = no moisture ) and the junction box/control

box for moisture content. This situations may induce a

false signal in the moisture detecting circuit. If none of

the above tests prove conclusive, the pump(s) should be

pulled and the source of the failure identifi ed and repaired.

IF A MOISTURE DETECT HAS OCCURRED SCHEDULE

MAINTENANCE AS SOON AS POSSIBLE.

Wire Size -

If additional cord is required consult a qualifi ed

electrician for proper wire size.

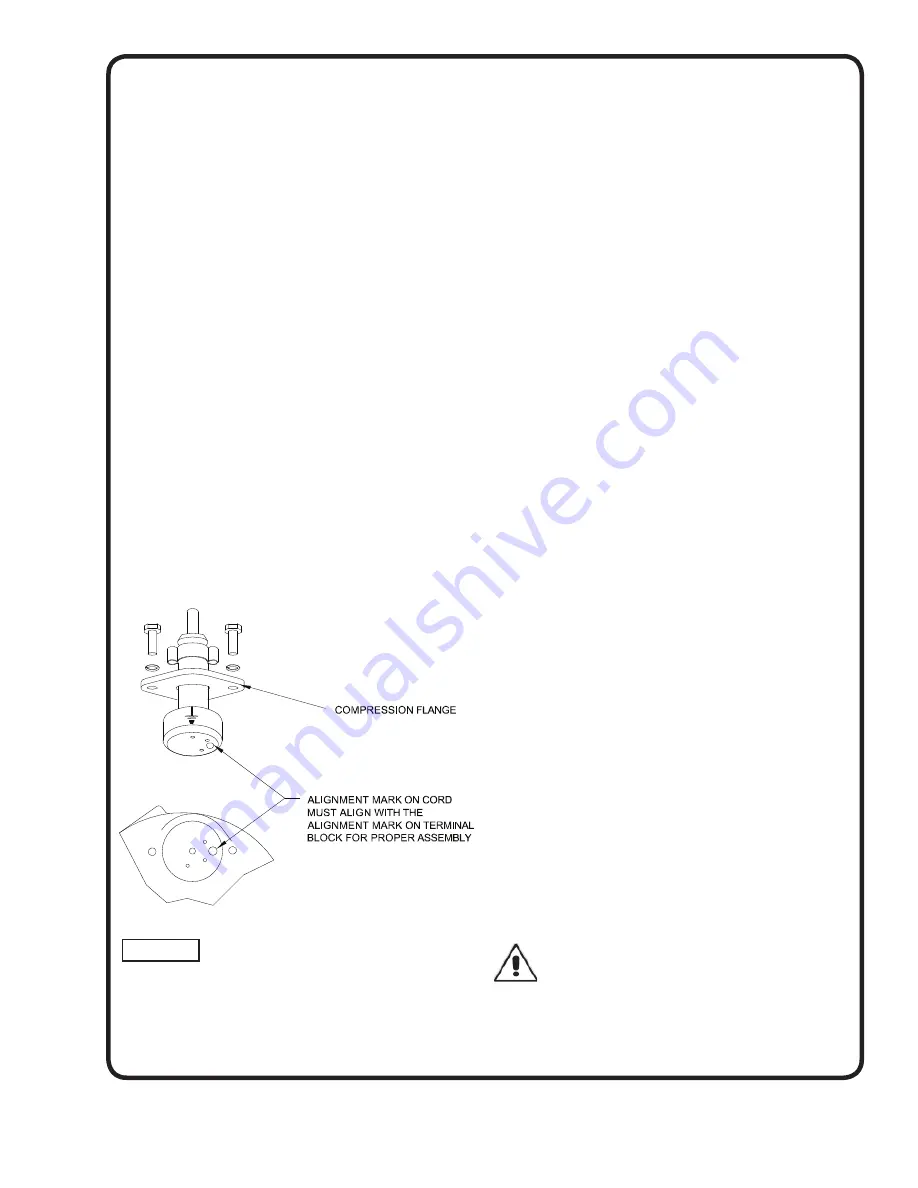

CORD CONNECTIONS:

(Except 5002L & 5022L)

Power/Control Cord-

Insert female end of cord plug into

housing bore aligning alignment mark with hole in terminal

block see Figure 2. Tighten bolts on compression fl ange

until fl ush with motor housing.

SERVICE:

Lubrication:

Anytime the pump is removed from operation, the cooling

oil in the motor housing (10) should be checked visually for

oil level and contamination.

Checking Oil:

Motor Housing -

To check oil, set unit upright. Remove

pipe plug (36) from motor housing (10). With a fl ashlight,

visually inspect the oil in the motor housing (10) to make

sure it is clean and clear, light amber in color and free from

suspended particles. Milky white oil indicates the presence

of water. Oil level should be just above the motor when

pump is in vertical position.

Testing Oil:

1.)

Place pump on it’s side, remove pipe plug (36), from

motor housing (10) and drain oil into a clean, dry

container.

2.)

Check oil for contamination using an oil tester with a

range to 30 Kilovolts breakdown.

3.)

If oil is found to be clean and uncontaminated

(measuring above 15 KV. breakdown), refi ll the motor

housing as per section “

Replacing Oil

”.

4.)

If oil is found to be dirty or contaminated (or measures

below 15 KV. breakdown), the pump must be

carefully inspected for leaks at the shaft seals (5)

(40), cord assemblies (49, 50, 15, 16) , square

rings (8), (14), (29) and pipe plugs, (36) before

refi lling with oil. To locate the leak, perform a pressure

test as per section “

Pressure Test

”. After leak is

repaired, dispose of old oil properly, and refi ll with new

oil as per section “

Replacing Oil

”.

Replacing Oil:

Motor Housing -

Drain all oil from motor housing

and dispose of properly per Local and Environmental

Standards. Set unit upright and refi ll with new cooling

oil as per Table 1 (see parts list for amount). Fill to just

above motor as an air space must remain in the top of

the motor housing to compensate for oil expansion. Apply

pipe thread compound to threads of pipe plug (36) then

assemble to motor housing (10).

Seal Chamber -

Drain all oil from seal chamber and

dispose of properlt per Local and Environmental

Standards. Set unit on its side, with plug (36) upward, and

refi ll with new oil as per Table 1 (see parts list for amount).

Apply pipe thread compound to threads of pipe plug (36)

and assemble to seal plate (6).

Warning ! - Do not over

fi

ll oil. Over

fi

lling of

motor housing with oil can create excessive and

dangerous hydraulic pressure which can destroy

the pump and create a hazard. Over

fi

lling oil

voids warranty.

FIGURE 2

Содержание SGV3032L

Страница 10: ...10 ALL EXCEPT SGV5002L SGV5022L ...

Страница 11: ...11 ...

Страница 20: ...Notes ...