4

OPERATION

KNOW YOUR JACK

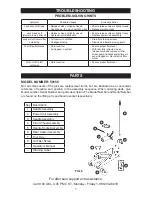

Compare Fig. 4 illustration with your jack

BEFORE operation to become familiar with

the location of various jack components.

SPECIFICATIONS

Rated Capacity: 4 Ton / 8000 Lbs

Jack Dimensions: 27-1/4” x 13-1/4” x 6-

7/16”

Lifting Range: 5-3/4” ~ 19-13/16” (Approx.)

(145 - 504 mm)

Oil Capacity: 235 c.c.

Net Weight: 89.1 Lbs (Approx.)

BEFORE USE

• Read the operator’s manual completely

and familiarize yourself thoroughly with the

product, its components and recognize the

hazards associated with its use.

• Occasionally during shipping and handling,

the hydraulic oil in jack may become

unstable or air may trapped in the system,

both of which can interfere with the jacks

lifting performance.

•

To stabilize the hydraulic oil, it is

recommended to cycle the jack a few times

without applying load:

• Close release valve by turning the jack

handle clockwise until tight.

• Pump the handle until the jack saddle

reaches its maximum height.

• Open release valve by turning jack

handle counter-clockwise, but no more

than 1/2 full turn at a time. Allow the

saddle to reach its lowest position.

• Repeat the above procedure a few

times.

•

To release air from the hydraulic system:

• Open the release valve by turning the

jack handle counterclockwise, but never

by more than 1/2 full turn at a time.

• Remove the oil filler screw from the

cylinder (Fig. 4).

• Rapidly pump jack handle through

several full strokes.

• Reinstall the oil filler screw into the

cylinder again and jack is now ready to

use.

BEFORE EACH USE

Make a visual inspection before each use

of the floor jack by checking for abnormal

conditions, such as cracked welds, leaks and

damaged, loose, or missing parts.

DAMAGE TO JACK

If you think jack has been subjected to an

abnormal load or shock, have it inspected for

damage at a Sears or other qualified service

center before using it again.

FIG. 4

Jack Handle

Handle

Socket

Release Valve

(inside Handle

Socket, engage

with Jack Handle)

Rear Castor

Front Wheel

Saddle

Lifting Arm

Magnetic Tool Tray

(remove to access Oil Filler Plug)

Oil Filler Plug

(located beneath Tool Tray)