15

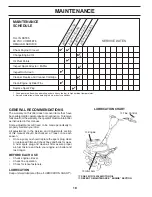

STORAGE

ENGINE OIL

Drain oil (with engine warm) and replace with clean oil. (See

“ENGINE” in the Maintenance section of this man ual).

CYLINDER(S)

• Remove spark plug.

• Pour 1 ounce (29 ml) of oil through spark plug hole

into cylinder.

• Pull starter handle slowly several times to distribute

oil.

• Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

•

Replace your gasoline can if your can starts to rust. Rust

and/or dirt in your gasoline will cause problems.

• If possible, store your unit indoors and cover it to give

protection from dust and dirt.

• Cover your unit with a suitable pro tec tive cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows con den sa tion to form and

will cause your unit to rust.

IMPORTANT:

NEVER COVER TILLER WHILE ENGINE AND

EXHAUST AREAS ARE STILL WARM.

Immediately prepare your tiller for storage at the end of the

season or if the unit will not be used for 30 days or more.

WARNING: Never store the tiller with

gasoline in the tank inside a build ing

where fumes may reach an open flame

or spark. Allow the engine to cool before

storing in any enclosure.

TILLER

•

Clean entire tiller (See “CLEANING” in the Maintenance

section of this manual).

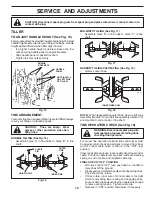

• Inspect and replace belts, if nec es sary (See belt re-

place ment in struc tions in the Service and Ad just ments

section of this manual).

•

Lubricate as shown in the Maintenance section of this

manual.

• Be sure that all nuts, bolts and screws are securely

fastened. Inspect moving parts for damage, break age

and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

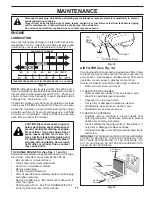

ENGINE

FUEL SYSTEM

IMPORTANT:

IT IS IMPORTANT TO PREVENT GUM DEPOSITS

FROM FORMING IN ESSENTIAL FUEL SYSTEM PARTS SUCH

AS THE CARBURETOR, FUEL FILTER, FUEL HOSE, OR TANK

DURING STORAGE. ALSO, EXPERIENCE INDICATES THAT

ALCOHOL BLENDED FUELS (CALLED GASOHOL OR USING

ETHANOL OR METHANOL) CAN ATTRACT MOISTURE WHICH

LEADS TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE.

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines and

car bu re tor are empty.

• Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may occur.

NOTE:

Fuel stablizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline in fuel tank or storage

container. Always follow the mix ratio found on stablizer

container. Run engine at least 10 minutes after adding

stablizer to allow the stabilizer to reach the carburetor.

Do not drain the gas tank and carburetor if using fuel

stabilizer.

Содержание 944.628655

Страница 28: ...03 24 11 CL PRINTED IN U S A 02488 ...