CSESJ350A / CSESJ350ANG

5

11/10/2020

HYDRAULIC JACK MAINTENANCE GUIDE

IMPORTANT:

Service jacks are designed for lifting purposes only; always support raised load with jack stands.

REGULAR MAINTENANCE

• MONTHLY or as necessary (depending on usage)

1. Using a grease gun, add grease to grease fitting in the lift arm pivot shaft. (Use a multi-purpose NLGI type grease only.)

2. Lubricate all linkages and pivot points. (Use white lithium spray grease only.)

3. Remove handle; lubricate handle receptacle and handle end. (Use white lithium spray grease only.)

4. Lubricate both rear casters, bearing and both front wheels. (Use white lithium spray grease only.)

5. Tighten all accessible hardware.

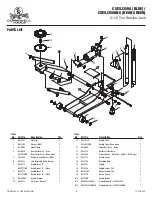

CSESJ350A (BLUE) /

CSESJ350ANG (NEON GREEN)

3-1/2 Ton Service Jack

*

*

*

2

4

4

1

2

2

2

3

Numbers shown in this

illustration match the

step numbers above

(Regular Maintenance)

View when lift arm is raised

View from rear

NOTE:

Premature wearing of parts or components caused by loose or missing hardware that have not been replaced or tightened in a correct and timely

manner are not eligible for warranty consideration.

*