5

CLUTCH REASSEMBLY

During reassembly of the clutch, all parts should receive a thin

coating of a mixture of 10W machine oil and NLGI 2-EP grease.

When installing the sear pin, No. 867909, the rounded end goes

into the clutch cam first. The sear plunger, No. 867886, goes into

the clutch cam cupped end first. All parts installed into the clutch

spindle and clutch cam, No. 867892, should be checked for

smooth operation before complete assembly of the clutch.

"H" RIGHT ANGLE HEAD ASSEMBLY

The driven gear and spindle ball bearing 847846, are pressed onto

the spindle shaft. Insert spindle shaft and gear into housing and

replace retainer ring No. 869033. Install the pinion gear and related

components into the rear of the angle head.

"K" RIGHT ANGLE HEAD ASSEMBLY

Slip pinion needle bearing, No. 869864, (unstamped end first) on

the pinion No. 202200, and press (press on the bearing's stamped

end) the bearing in to a depth of 7/8" from the face of the bearing

bore. Install pinion ball bearing, No. 847846 and bearing retainer,

No. 863564, in the head and tighten retainer securely using the 5/

8" hex nut and 5/8" deep socket. Using a suitable driver through the

hole in the top of the head, drive the pinion back to make sure it is

seated properly in the head.

"M" RIGHT ANGLE HEAD ASSEMBLY

Assemble the spindle and related components in the head and

securely tighten (left hand threads) the bearing cap, No. 864396.

Use bearing spacer, No. 869050, to press the pinion needle

bearing, No. 863360, (press on the bearing's stamped end) in the

head. Install ball bearing, No. 847846, and bearing retainer, No.

863564, in the head and tighten retainer securely using the 5/8"

hex nut and 5/8" deep socket.

TRIP ROD SIZING

A. Old Trip Rod

The tool should be reassembled complete less the trip rod, clutch,

and clutch housing. With the air on, install the trip rod and clutch

into the tool and measure the distance between the rear face of the

ball retainer, No. 867881, and the front face of the gear case. Turn

the air off and depress the clutch assembly and measure clutch

travel. Clutch travel must be at least 3/32". If not, the trip rod should

be replaced.

B. New Trip Rod

Assemble the tool completely, less the clutch housing, and con-

nect the tool to the air supply. Screw (left hand threads) the clutch

housing onto the gear case until air exhausts from the backhead.

Measure the gap between the clutch housing and gear case. Grind

this amount plus 5/64" minimum off the trip rod. IMPORTANT

NOTE: If the trip rod is too long the tool can ratchet or not shut off.

If the tool has a drop in power or RPM the trip rod can be to short.

Remember the trip rod length is not the only factor that causes

these problems. If you feel sure you have cut the trip rod length

properly look for other problems.

MOTOR DISASSEMBLY

Use a soft-faced hammer to drive the rotor out of the front rotor

bearing. This will allow the cylinder and four (4) rotor blades to be

removed from the rotor. Set the rear bearing plate on the vise jaws

with the rotor hanging down. Use a 7/32" punch to drive the rotor

out of the rear rotor bearing.

BACKHEAD DISASSEMBLY

Unscrew and remove the inlet bushing No. 202883, for inspection

and cleaning of the air inlet screen No. 833300. Replace the screen

if clogged or torn. Remove flow valve No. 203036, by removing

retainer ring No. 864271, then unscrewing flow valve with screw-

driver.

REASSEMBLY — GENERAL

All parts should be washed in a solvent and inspected for damage

or wear. Particular attention should be given to all bearings, gears,

gear pins, and rotor blades as failure of these parts could cause

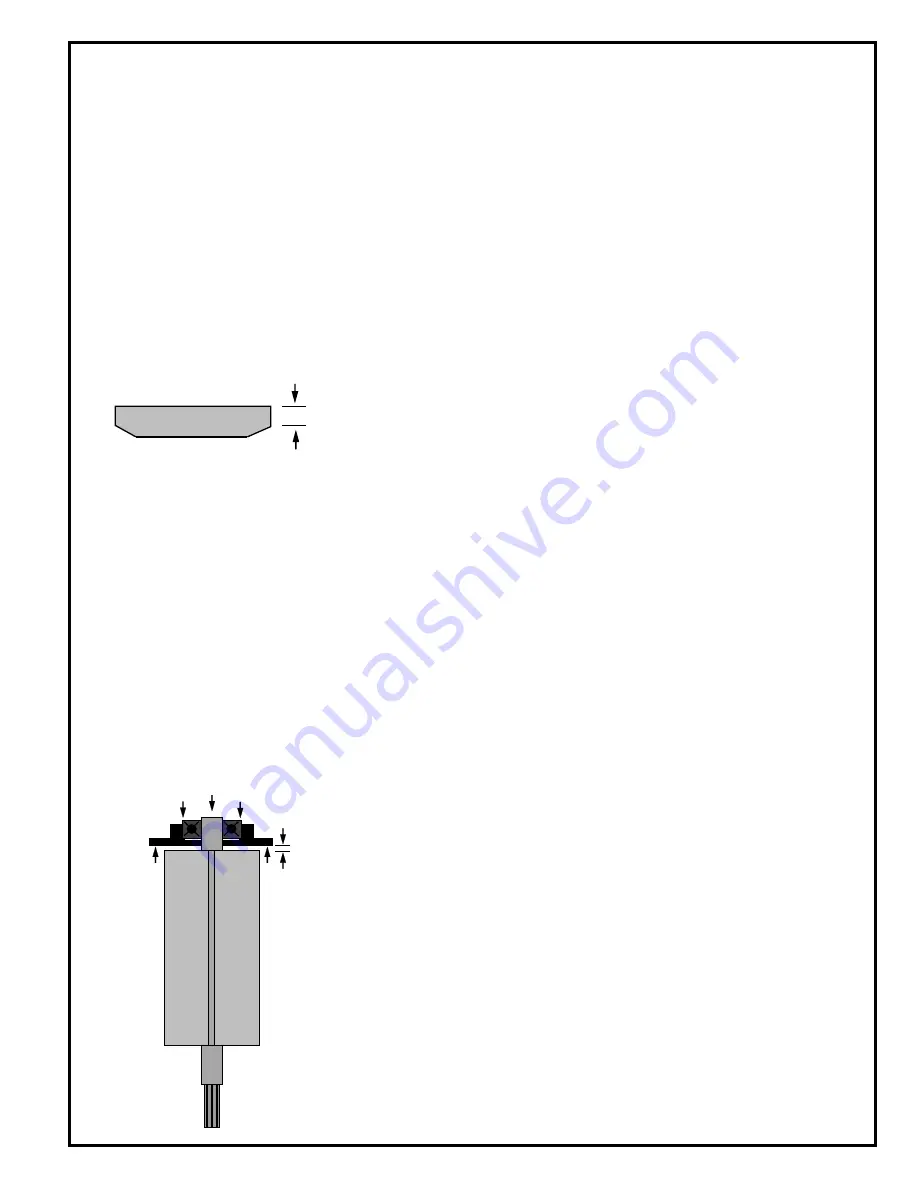

damage to more expensive parts. Rotor blades should be replaced

if they measure less than 3/16" on either end.

Inspect and replace any "O"-rings or seals that show signs of wear

or deterioration. All gears, gear pins, and open bearings should

receive a generous amount of NLGI 2-EP grease during reassem-

bly.

Reassembly of all of the various subassemblies is in the reverse

order of disassembly; however, the following paragraphs list some

of the more important reassembly procedures.

MOTOR REASSEMBLY

Assemble the rear rotor bearing and rear bearing plate (press on

the bearing's inner race) onto the rear rotor shaft until there is

approximately .0015" clearance between the plate and rotor.

Assemble the four (4) rotor blades, cylinder, front bearing plate,

and front rotor bearing (press on the bearing's inner race) to the

rotor assembly. After final assembly, the cylinder should be held

firmly, but not tightly between the two (2) bearing plates and the

rotor should turn freely and not rub either bearing plate.

Must be replaced if less than

3/16" (4.7mm) on either end.

.0015" (.038mm)

Clearance

Содержание Cleco 88 Series

Страница 22: ...22 NOTES...

Страница 23: ...23 NOTES...