SERIES CHARGING CONTACTS MANUAL

12

WARNING

Before performing inspections and/or maintenance procedures, ensure all power is disconnected and all safety procedures are followed.

SECTION 3 - MAINTENANCE

System Inspections

1.

Perform the first inspection after the charging system has

cycled 100 times.

2.

Ensure that all electrical and mechanical connectors are

properly secured, and that the mechanical alignment is within

specification. Reference the provided drawing for additional

alignment detail.

3.

Perform periodic inspections every 15,000 – 20,000 charging

cycles. During these inspections ensure that all electrical and

mechanical connectors are properly secured.

Brushes

1.

Inspect the electrical brushes on the collector for wear. If

the brush is worn to the wear line etched into the side of the

brush, the brush is considered worn and should be replaced.

See

Figure 3-1.

2.

Inspect connection at the brush post to ensure they are still

torqued to 5.7 N-m(50 IN-LB) on the power brushes and 1.1

N-m (10 IN-LB) on the signal brushes.

3.

Inspect the contact surfaces on the base plate for wear.

4.

Remove surface dirt, oxidation, pitting, and other contaminants

from the contact surfaces via a brass brush or 320 grit sand

paper.

CAUTION

Do not use solvents or chemicals to clean the contact surfaces

and/or brushes.

Brush Springs

1.

Inspect and test the brush springs to ensure proper contact

pressure.

2.

Signal brush force for a single brush should measure between

.40-.55 lbf at minimum compressed distance for operation

(.5mm from free air state) and 2.00-2.45 lbf at maximum

compressed distance for operation (20.5mm). Power brush

force for a single brush should measure between 10.00-13.15

lbf at minimum compression distance for operation (.5mm from

free air state) and 18.00-22.50 lbf at maximum compressed

distance for operation (20.5mm). See

Figure 3-2

Electrical Connections

1. Inspect all electrical connections for corrosion.

2. Ensure that all fasteners are properly tightened.

NOTE

•

Poor electrical connections can lead to increased

electrical resistance and poor charging performance.

0.787 (20)

Minimum

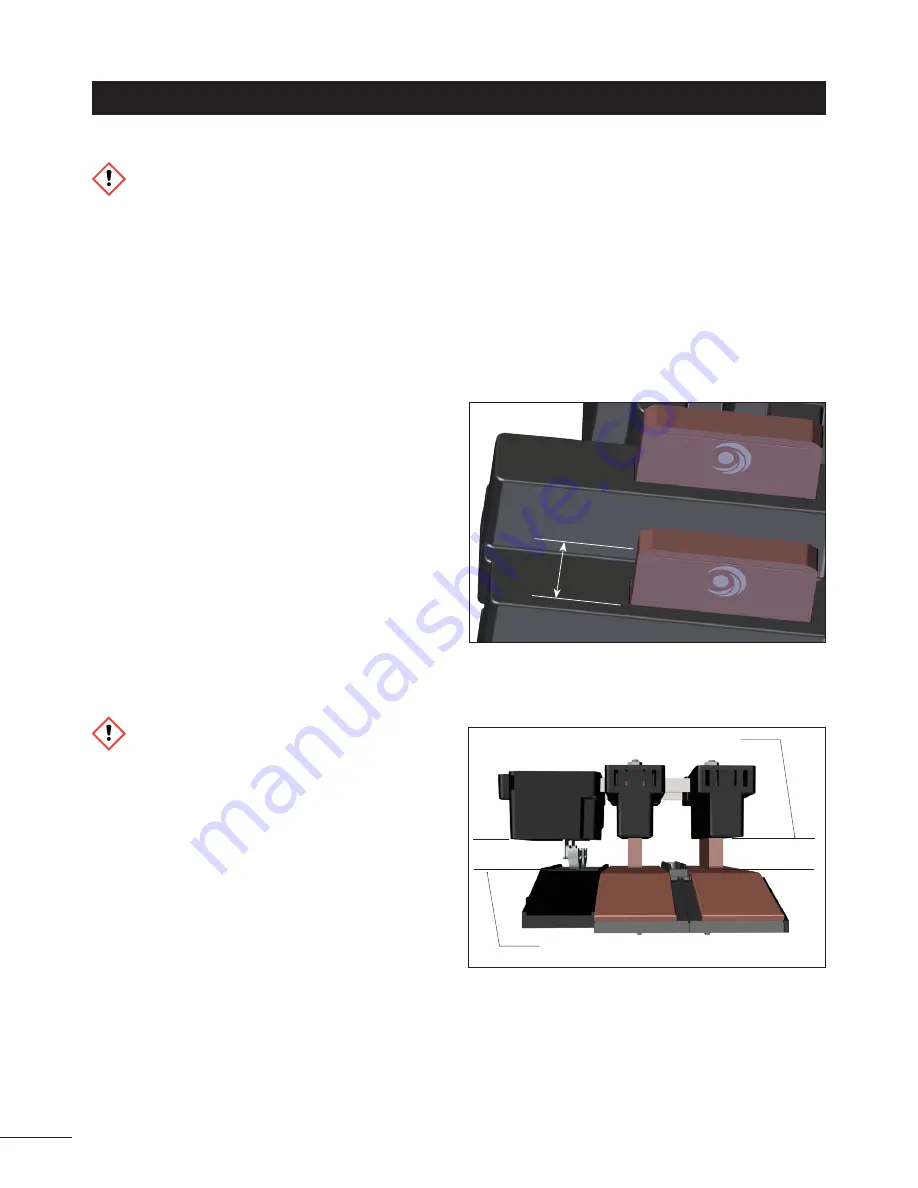

Figure 3-1:

Brush Height Measurement

Figure 3-2:

Target Mounting Distance at Mid-Stroke

13.3 +/- 10 mm

11.6 +/- 10 mm

Signal contacts

Power contacts