10

11

user manual

Cross

line laser

en

CONDTROL Octoliner Servo

user manual

Cross

line laser

en

CONDTROL Octoliner Servo

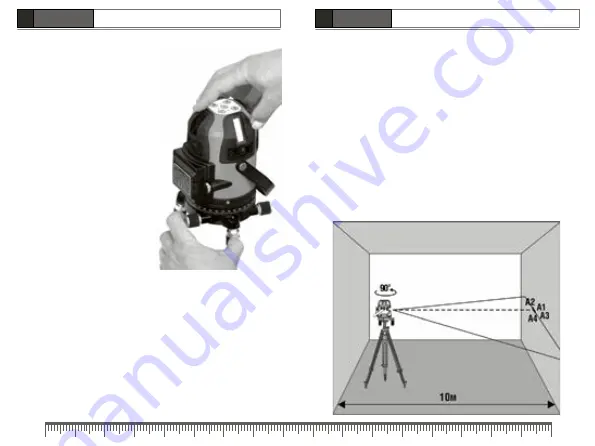

To facilitate rotation of the product

about its axis slightly pull and hold

the left screw of fine adjustment

(Figure 1).

Press

oN/oFF

to turn off the

product.

Attention!

To increase the

operating time and avoid the risk of

unintentional blindness switch the

laser on only when you are ready to

make measurements.

If operated near objects or air

streams with different from the

environment temperature the

laser line may tremble due to

heterogeneity of the atmosphere.

The longer is the distance, the more

trembling can be observed.

The width of the laser line increases with the increasing of the

operating distance. The layout should be made along the axis of the

laser line. For maximum accuracy, use the middle portion of the laser

line.

It should be noted that the shape of the laser line on the object’s

surface (e.g., walls, ceilings, etc.) depends on the curvature and tilt of

the surface relative to the laser plane.

ACCURACY CHECK

Check of horizontal lines

Check of horizontal line is carried out by using 2 parallel walls located

opposite each other at a distance of 10 m.

1. Put the product as close as possible to one of the walls. Turn on

horizontal planes. Mark location of horizontal line on the distant wall

as A1.

2. Turn the product by 90°, mark location of horizontal line on the

distant wall as A2.

3. Turn the product by 90° again, mark location of horizontal line on

the distant wall as A3.

4. Turn the product by 90° once again, mark location of horizontal line

on the distant wall as A4.

5. Measure vertical deviation of horizontal line between points а1 - а4.

If deviation exceeds 1 mm – please contact service center.

Figure 1