408- 4457

Rev

J

12

of 16

5.4.

900-

m

m Easy Strip or Semi- Tight Buffered Fiber

Connector

Assembly

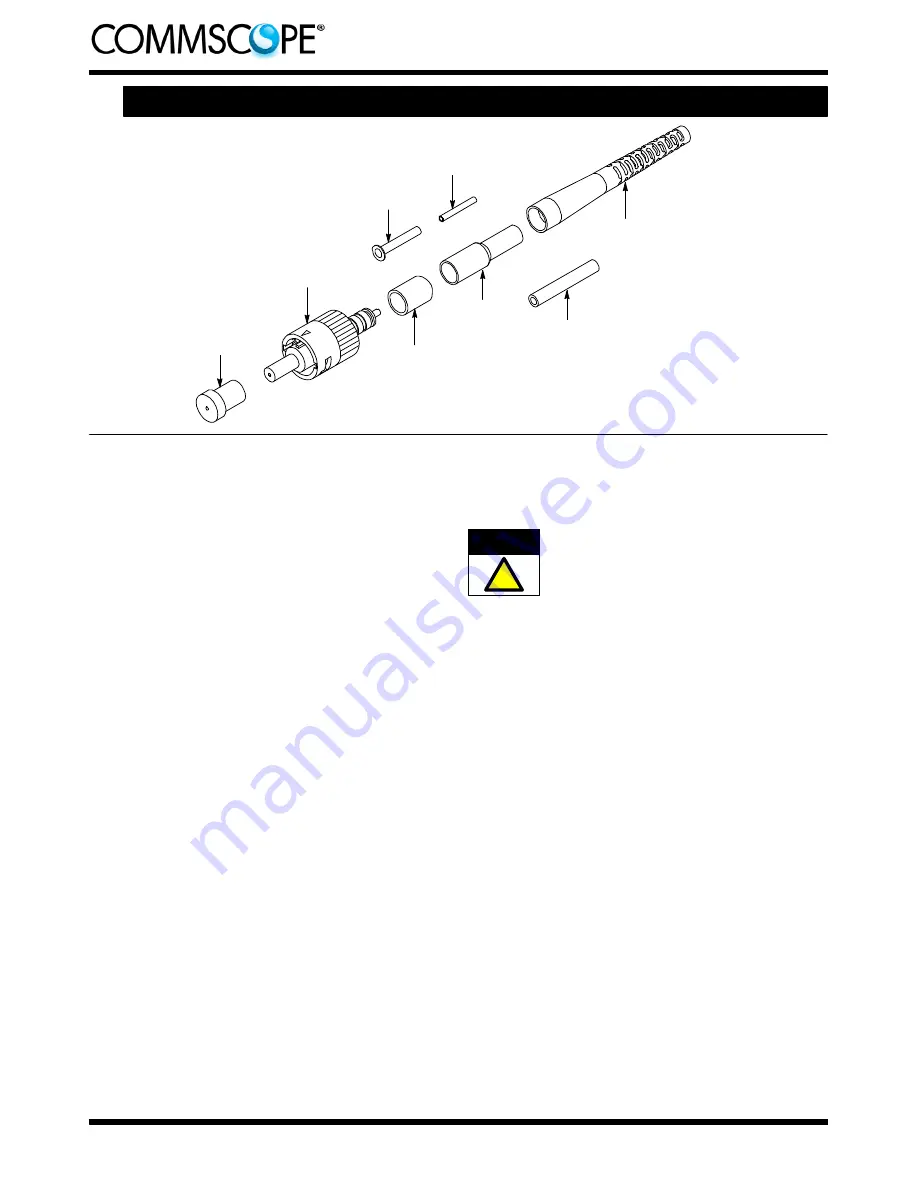

Plunger

Protective

Cap

Strain

Relief

Crimp

Eyelet

Inner

Eyelet

Small

Tubing

Kit Components Required

(Discard Other Components)

Clear

Tubing

Connector kit is shipped with these installed onto connector

assembly. Keep them in place until ready for assembly.

Ferrule

Protective

Cover

A. Preparing 900-

m

m Easy Strip or Semi- Tight

Buffered Fiber

(Figure 12)

1. Place the inner eyelet, small end first, inside the

clear tubing so that the flange ofi nner eyelet is

against the end of the tube. See Figure 12,

Detail A.

2. Slide the strain relief (long), clear tubing (with

inner eyelet inside), and crimp eyelet onto the

cable. See Figure 12, Detail B.

3. Remove the ferrule protective cover and the

plunger protective cap from the connector

assembly. Keep the cover; discard the cap.

4. Insert the small (white) tubing into the connector

plunger until the tubing bottoms. See Figure 12,

Detail C.

5. Push the connector into the holder of the cable

holder with the ferrule protective cover facing

outward. Make sure that the connector butts

against the lip of the arm of the cable holder. See

Figure 12, Detail D.

6. Slide the fiber into the channel marked

“BUFFER” on the cable holder. Make sure that the

tip of the fiber butts against the end of the channel.

See Figure 12, Detail D.

7. Mark the fiber at each cross--slot of the channel.

See Figure 12, Detail D. Also, place a mark on the

buffer at the end of the channel. Remove the fiber

from the channel.

8. Using the strip tool, strip the 250--

m

m fiber

coating and buffer back to the first mark. It is

recommended holding the tool at an angle to the

fiber and stripping the coating in three sections.

See Figure 12, Detail E. Clean the fiber with

an alcohol fiber wipe to remove the fiber coating

residue.

Before using the strip tool, make sure that the “V”

opening is clean. Ifi t is not clean, the fiber could

break. Only use isopropyl alcohol to clean the

tool.

9. Using the strip tool, apply slightly less pressure

than when stripping 125--

m

m fiber, and strip the

buffer only (leave the 250--

m

m fiber coating in

place) to the second mark. Practice this first.

10. Mark the 250--

m

m fiber coating at the shoulder

of the 900--

m

m buffer. Strip the buffer to the third

mark.

B. Cleaving

(Figure 13)

1. Open the fiber clamp of the fiber optic cleaver.

Press the button, and slide the carriage back

(toward the fiber clamp). Then move the fiber slide

back until it stops.

2. Place the stripped fiber into the slot so that the

end of the buffer is at the 8--mm marking. See

Figure 13, Detail A.

3. While applying pressure on the buffer, carefully

slide the fiber slide forward (toward the carriage)

until it stops. See Figure 13, Detail B.

4. Gently close the fiber clamp, and slide the

carriage forward. DO NOT touch the button while

sliding the carriage. See Figure 13, Detail C.

5. Open the fiber clamp, and move the fiber slide

back until it stops.

6. Remove the cleaved fiber, and properly dispose

of the scrap fiber.

CAUTION

!