The ASB series booster pump is an all-in-one compact and reliable automatic

multistage centrifugal booster pump, which integrates motor, pump, accumulator,

pressure switch and flow switch in one set. The flow switch equipped with the

pump prevents the pump from continuously starting and stopping under small

discharge, and provide stable water supply. It is very suitable for domestic water

supply.

Operating Conditions

1. Ambient Temperature : +5 ºC ~ +40 ºC

2. Liquid Temperature

Regular Model : +5ºC ~ +40ºC

Hot Water Model : +5ºC ~ +90ºC

3. Maximum Operating Pressure : 6 kg/cm

2

4. Rated Discharge Head / Height

ASB25(H)

: 1.5 kg/cm

2

/ 15 m

ASB50(H)

: 2.0 kg/cm

2

/ 20 m

ASB100(H) : 2.5 kg/cm

2

/ 25 m

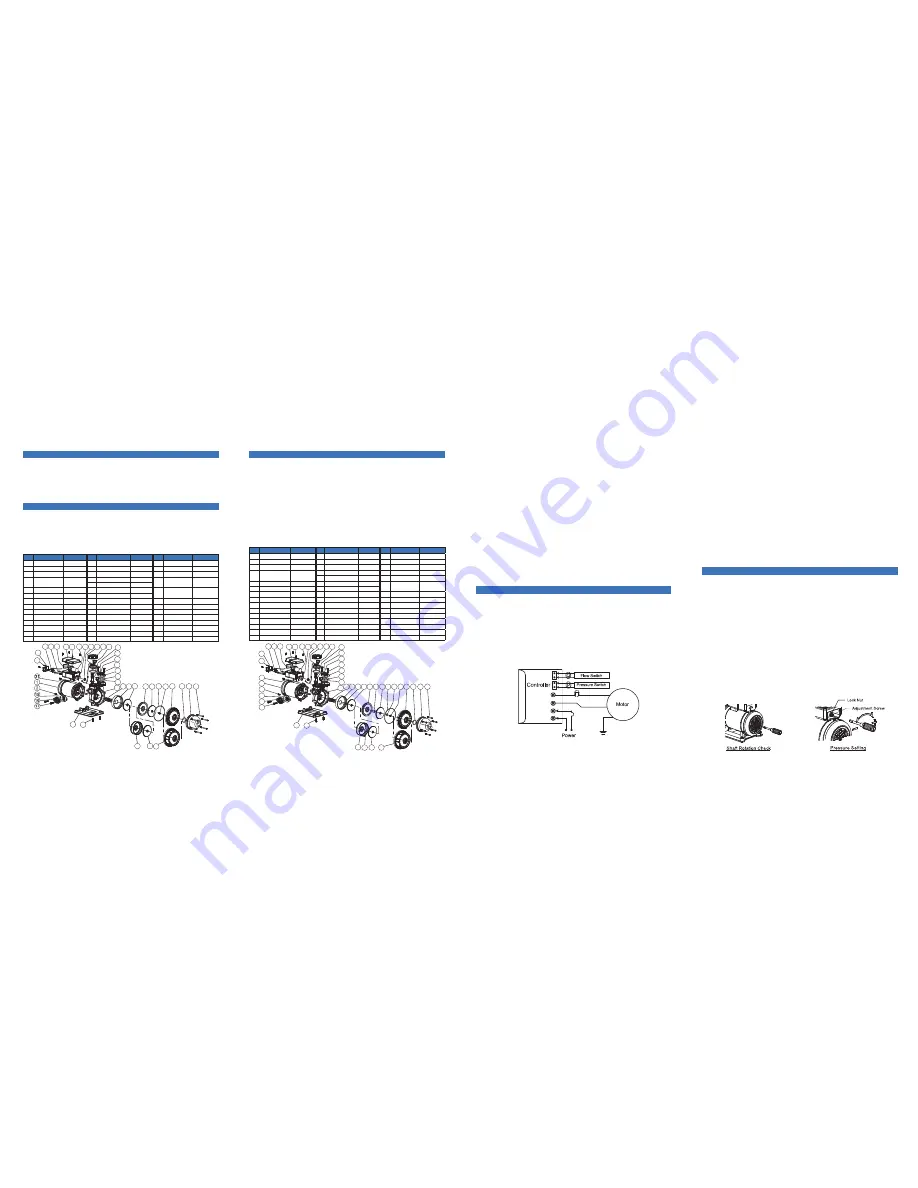

Item

Name

Description

Item

Name

Description

Item

Name

Description

1

Motor

1

Φ

2 Poles

15

Inlet Flange Gasket

Rubber

25

Bolt

S45C

2

Bolt

S45C

16

Inlet Flange

NYLON

26

Wiring Box Cover

NYLON

3

Pump Casing

Noryl

17

Flange Bolt

SUS304

27

Bolt

S45C

18 Outet Flange Gasket

Rubber

4

Mechanical Seal

NBR

+Carbon

19

Outlet Flange

NYLON

28

Controller

Triac-Based

5

Impeller Chamber

NORYL

20

Flange Bolt

SUS304

6

Impeller

NORYL

21-1

Priming Plug

NYLON

29

Pressure Switch

For Turn-On

Pressure Setting

7

Diffuser

NORYL

21-2 Air Evacuation Plug

NYLON

30

Switch Cover

NYLON

8

Impeller

NORYL

22-0

Flow Switch Set

Flow Detection

31

Thermal Protector

Auto Reset

9

O Ring

NBR

22-1

Spring

SUS304

32

Pump Base

ABS

10

Bolt

SUS304

22-2

Stopper

NORYL

33

Bolt

S45C

11*

1

Pump Cover

NYLON

22-3

Seal O Ring

NBR

34*

2

Impeller Chamber

NORYL

12

O Ring

NBR

22-4

Locking Ring

NYLON

35*

2

Impeller

NORYL

13

Pressure Tank

SUS304

23

Seal Gasket

Rubber

36*

2

Pump Cover

NYLON

14

Pump Cover Bolt

SUS304

24

Wiring Box

NYLON

37

Motor Capacitor

Plastic Film

*1 Parts for 60 Hz models.

*2 Parts for 50 Hz models.

Installation and Piping

1. For stable operation, please mount and bolt the booster pump securely. The

installation place must be dry with good ventilation and adequate space for

future maintenance and service. A proper shelter is required for outdoor

installation; exposure to rain will damage the insulation of electrical wiring.

Construction ( ASB-H Hot water Model with stainless steel impeller.)

Item

Name

Description

Item

Name

Description

Item

Name

Description

1

Motor

1

Φ

2 Poles

13

Pressure Tank

SUS304

24

Wiring Box

NYLON

2

Bolt

S45C

14

Pump Cover Bolt

SUS304

25

Bolt

S45C

3

Pump Casing

Noryl

15

Inlet Flange Gasket

Rubber

26

Wiring Box Cover

NYLON

16

Inlet Flange

NYLON

27

Bolt

S45C

4

Mechanical Seal

Viton

+Carbon*

3

17

Flange Bolt

SUS304

28

Controller

Triac Based

5

Impeller Chamber

NORYL

18 Outlet Flange Gasket

Rubber

6

Impeller

SUS304*

3

19

Outlet Flange

NYLON

29

Pressure Switch

For Turn-On

Pressure Setting

6-1*

3

Shaft Sleeve

PPS

20

Flange Bolt

SUS304

30

Switch Cover

NYLON

7

Diffuser

NORYL

21-1

Priming Plug

NYLON

31

Thermal Protector

Auto Reset

8

Impeller

SUS304*

3

21-2 Air Evacuation Plug

NYLON

32

Pump Base

ABS

8-1*

3

Shaft Sleeve

PPS

22-0

Flow Switch Set

Flow Detection

33

Bolt

S45C

9

O Ring

NBR

22-1

Spring

SUS304

34*

2

Impeller Chamber

NORYL

10

Bolt

SUS304

22-2

Stopper

NORYL

35*

2

Impeller

SUS304*

3

10-1*

3

Shaft Sleeve

SUS304

22-3

Seal O Ring

NBR

35-1*

3

Shaft Sleeve

PPS

11*

1

Pump Cover

NYLON

22-4

Locking Ring

NYLON

36*

2

Pump Cover

NYLON

12

Tank O Ring

Silicon Rubber*

3

23

Seal Gasket

Rubber

37

Motor Capacitor

Plastic Film

Operation and Important Notes

Pressure Switch Adjustment

(a) Single Voltage Model Wiring

Description

Construction ( ASB Regular model with thermoplastic impeller.)

14

13

12

11

10

9

8

7

6

5

4

3

18

19

20

23

24

37

27

26

28

25

29

30

27

30

27

31

15

16

17

32

33

32

33

34

35 36

34

35

36

14

13

12

11

10

9

8

7

21-2

35-1

22-2

22-1

21-1

22-4

22-0

23

24

37

27

26

28

25

29

21-1

6-1

8-1

22-4

22-0

22-3

18

19

20

21-2

22-2

22-1

10-1

22-3

1

2

6

5

4

3

2. The pump should be installed as close as to the reservoir or well. For hot

water (40~90ºC) pumping, negative inlet pressure application is required to

avoid cavitations. Piping joints should be fitted carefully to prevent leak. Leak

in the suction piping will cause the pump suction capacity lost, while leak in

the discharge piping will cause a high frequency ON/OFF motor operation

while the faucets valves are closed.

*3 Parts or materials for hot water models

only.

*2 Parts for 50 Hz models.

*1 Parts for 60 Hz models.

3. Protection rubber films within the center of suction/discharge flange gaskets

(Part No. 15 & 18) muse be removed during installation.

4. Be careful not to allow the foreign objects (PVC adhesive gum, dirt, sand etc)

into the pump, otherwise the pump will be damaged and shortened the life.

It is recommended to use a strainer to prevent that.

5. Check the voltage and wiring of the motor power according to the connecting

diagram shown below or inside the cover. Be sure to arrange earth or circuit

breaker against electric leakage in accordance with local government electrical

code.

6. The pump thermal protector (Part No. 31) is designed to protect the pump

from dry run. It is also used to prevent hot water pumping which will damage

the pump structure. The electrical power will be cut off after several minutes

while dry run occurs, and will be turned on periodically. Shut off the electrical

power manually is recommended during the water shortage period to save

the energy.

7. An auto-reset thermal protector is equipped with the motor winding. Power

will be cut off when the motor winding temperature is abnormal, and will

restart when the abnormal temperature back to normal.

1. Before set the power on, the pump chamber and suction pipe must be filled

with water in accordance with the following:

2. Insert a crossed screwdriver into motor shaft end, and turn the shaft several

turns clockwise to check whether the pump can be rotated freely. If not,

disassemble and clean the pump chamber.

3. Double check the voltage and wiring of the motor power and then turn the

power switch ON. Open faucet or water appliances on the discharge piping

side. The water should be delivered after several seconds.

4. If the water does not be delivered after several minutes, turn off the pump

immediately. Repeat step 1 to pour water into the pump and suction piping,

and switch power ON and OFF continuously.

5. Once the water is pumped out, close and open the water appliances on the

discharge side repeatedly to check automatic ON/OFF operation.

6. Measure the motor current and check with the data shown on the nameplate.

If the current is over, check the voltage again.

7. When re-start the pump after long term shut down, please repeat step1~6 to

ensure the normal operation.

The pressure switch set is designed inside the control box. In general, the

pressure has been set by factory properly to meet most situations. However,

for some special cases, when the pump cannot operate normally, it can be

adjusted easily. Please check the trouble shooting procedures, and read the

following instructions carefully before to do it. For pressure adjustment, first

remove the switch cover, and loose the lock nut counterclockwise by using a

12mm wrench.

1. Motor fails to stop

It is because of the pressure setting too high. By using a flat-end screwdriver,

turn the screw counterclockwise slowly, until the motor stop; then, turn an extra

small rotation, about 5 degrees. Finally, check if the motor can start normally.

2. Motor fail to start

It is because of the pressure setting too low. By using a flat-end screwdriver,

turn the screw clockwise slowly, until the motor start, then an extra small rotation,

about 5 degree, is added. Finally, check if the motor can stop normally.

3. After the pressure setting, screw the lock nut, and put the cover back.

◎

For the negative inlet pressure application ( inlet water level is below the pump

input ), remove the priming plugs (Part No. 21-1 or 21-2), and pour water into

the pump via priming hole completely. Then, secure the priming plugs back.

◎

For the positive inlet pressure application ( inlet water level is higher than

pump input ), loose the priming plug (Part No. 21-2), and then secure it after

the water drain out from the priming hole.