507768-04P

Page 13 of 56

Issue 1933

NOTE:

Heavy-gauge sheet metal straps may be used to

suspend the unit from roof rafters or ceiling joists. When

straps are used to suspend the unit in this way, support

must be provided for both the ends. The straps must not

interfere with the plenum or exhaust piping installation.

Cooling coils and supply and return air plenums must be

supported separately.

NOTE:

When the furnace is installed on a platform or with

the horizontal suspension kit in a crawl space, it must be

elevated enough to avoid water damage, accommodate

drain trap and to allow the evaporator coil to drain.

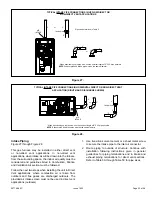

Platform Installation of Horizontal Unit

1. Select location for unit keeping in mind service and

other necessary clearances. See Figure 18.

2. Construct a raised wooden frame and cover frame

with a plywood sheet. If unit is installed above finished

space, fabricate an auxiliary drain pan to be installed

under unit. Set unit in drain pan as shown in Figure

20. Leave 8 inches for service clearance below unit for

condensate trap.

3. Provide a service platform in front of unit. When

installing the unit in a crawl space, a proper support

platform may be created using cement blocks.

4. Route auxiliary drain line so that water draining from

this outlet will be easily noticed by the homeowner.

5. If necessary, run the condensate line into a condensate

pump to meet drain line slope requirements. The

pump must be rated for use with condensing furnaces.

Protect the condensate discharge line from the pump

to the outside to avoid freezing.

6. Continue with exhaust, condensate and intake piping

installation according to instructions.

Figure 20.

Return Air - Horizontal Applications

Return air may be brought in only through the end of a

furnace installed in the horizontal position. The furnace

is equipped with a removable bottom panel to facilitate

Filters

This unit is not equipped with a filter or rack. A field provided

filter is required for the unit to operate properly. Table 1 lists

recommended filter sizes.

A filter must be in place whenever the unit is operating.

Table 1.

Furnace Cabinet

Width

Filter Size

Side Return

Bottom Return

B (17-1/2”)

16 x 25 x 1 (1)

16 x 25 x 1 (1)

C (21”)

20 x 25 x 1 (1)

Duct System

Use industry approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution.

NOTE:

This furnace is not certified for operation in heating

mode (indoor blower operating at selected heating speed)

with an external static pressure which exceeds 0.5 inches

w.c. Operation at these conditions may result in improper

limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable

access panel should be installed in the supply air duct. The

access panel should be large enough to permit inspection

(by reflected light) of the heat exchanger for leaks after the

furnace is installed. The furnace access panel must always

be in place when the furnace is operating and it must not

allow leaks into the supply air duct system.

Return Air Plenum

NOTE:

Return air must not be drawn from a room where

this furnace, or any other gas fueled appliance (i.e., water

heater), or carbon monoxide producing device (i.e., wood

fireplace) is installed.

When return air is drawn from a room, a negative pressure

is created in the room. If a gas appliance is operating in

a room with negative pressure, the flue products can be

pulled back down the vent pipe and into the room. This

reverse flow of the flue gas may result in incomplete

combustion and the formation of carbon monoxide gas.

This raw gas or toxic fumes might then be distributed

throughout the house by the furnace duct system.

Return air can be brought in through the bottom or either

side of the furnace. If a furnace with bottom return air is

installed on a platform, make an airtight seal between the

bottom of the furnace and the platform to ensure that the

Содержание GUH96C

Страница 3: ...507768 04P Page 3 of 56 Issue 1933 Figure 1 Parts Arrangement...

Страница 37: ...507768 04P Page 37 of 56 Issue 1933 Figure 59 Trap Drain Assembly Using 1 2 PVC or 3 4 PVC...

Страница 43: ...507768 04P Page 43 of 56 Issue 1933 045B3 070B3 090C4 110C5 Figure 67 Typical Wiring Diagram...