IOM - DOUBLE ECCENTRIC BUTTERFLY VALVES

UNIWAT® VF791

©COMEV

AL

V

AL

VE SYSTEMS

Technical Dept. Ref. IOM - DOUBLE ECCENTRIC BUTTERFL

Y V

AL

VES, UNIW

AT® VF791 - Ed.20/07

Comeval V

alve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly updated data on www

.comeval.es

- When being replaced, the disc sealing (18) and the o-rings should always be slightly greased.

- Replacement of the disc sealing:

Due to the double-eccentric bearing the disc sealing can be replaced without disassembly of the disc. Valves up to

DN1000 must either be completely dismantled from the pipeline or at least disconnected from the pipeline on one side to

replace the disc sealing.

• Open the disc (14) until the disc sealing (18) emerges from the body (28).

• Unfasten the retainer screws (30).

• Remove retainer (17) and disc sealing.

• Clean the disc in the sealing zone.

• Check the seat ring in the body (19) for damage or deposits.

• Insert the new disc sealing into the groove of the disc and slightly grease it.

• Insert the hexagonal screws and fasten them crosswise, moderately and uniformly, checking that the disc sealing

is not protuding excessively.

- Replacement of the O-rings in the bearings:

Please consult us.

After any maintenance work please refer to chapters 5 and 6 for installation / commissioning.

Recommended Spare parts:

Use only original spare parts.

It is advisable to keep disc sealings and o-rings as spare parts. Other spare parts available are stem and disc. Type and

number of each spare part to be stored according to many factors: service level, valves quantity, etc. In many cases a

good choice is to keep complete valves as spare part.

8. TROUBLESHOOTING

In the event of malfunction or faulty operating performance, check that the installation and adjustment work has been

carried out and completed in accordance with this Manual.

9. TROUBLESHOOTING TABLE

Technical support always available through our website www.comeval.es or your local distributor.

Page 6

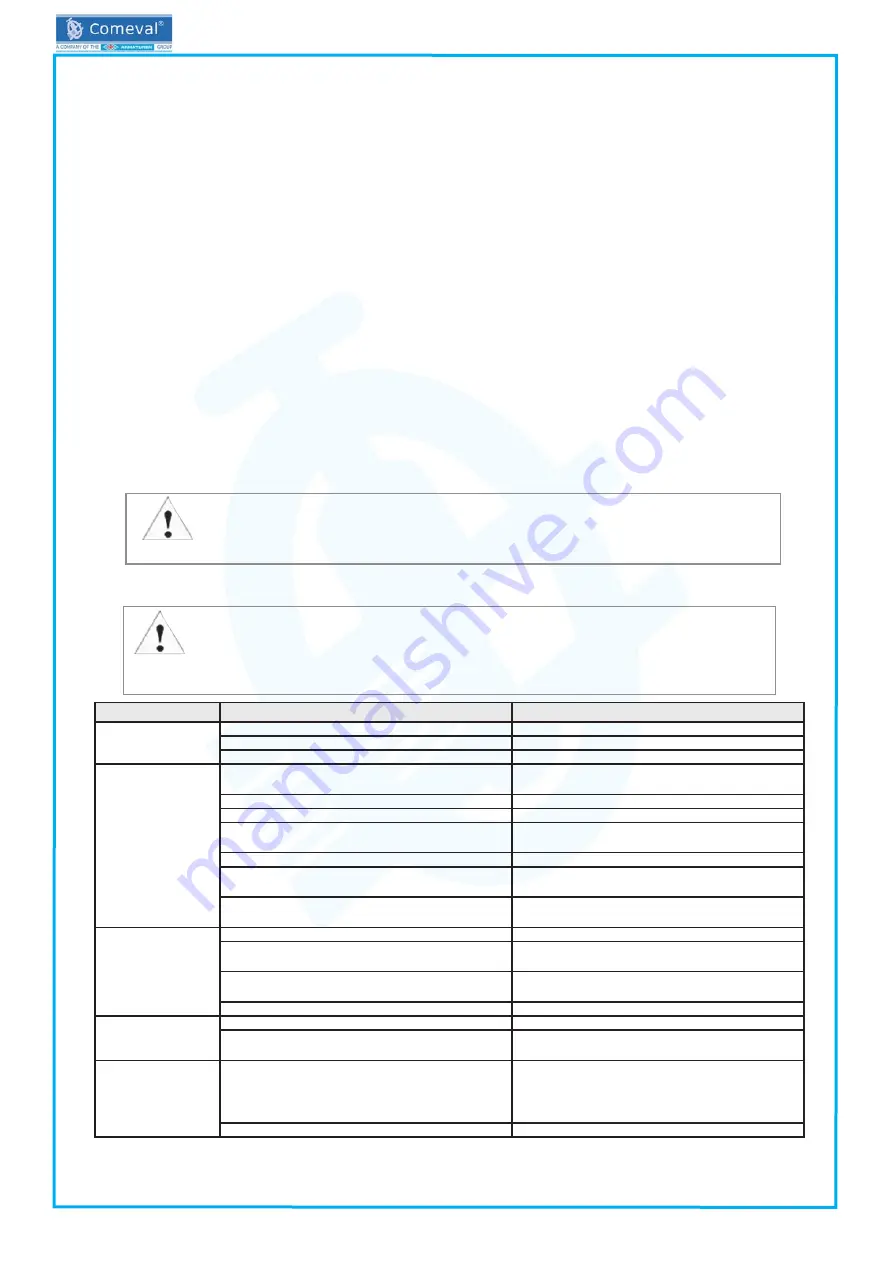

ATTENTION!

- Read the complete Manual before carrying out installation and repair work.

- Read chapter 6 before recommissioning.

FAULT

POSSIBLE CAUSE

CORRECTING MEASURES

No flow

Not enough flow

Flange covers or protection not removed

Clear valve entrances

Valve closed or almost closed

Check valve position

Piping clogged

Check piping system

Valve is impossible

or difficult to open

or close

Service conditions (e.g. medium, temperature)

may be outside the specified limits

Replace the valve

Consult the supplier or manufacturer

Power failure

Check the power supply

Actuator fault

Overhaul the actuator or replace it

Wrong direction of rotation

Turn in the correct direction

(anticlockwise for opening)

Solid matter is blocking the valve disc

Rinse or clean the valve

The parallel key on the stem has sheered off

Determine the cause and

replace the parallel key

Liquid has solidified between the bearings

If possible, flush the bearings and the stem via

the flushing connections

Valve is leaking

at closing

The disc is not completely closed

Put the disc into the closed position

Dirt trapped at closing

Move the disc and flush the valve in the open

position

Mechanical stop of the worm gear at closing

not well adjusted.

Adjust it according to chapter 6

The disc sealing or seat is damaged

Replace the disc sealing or repair the seat

Stem leakage

Stem seals or stem damaged or worn down

Revise and replace if needed

Excessive pressure or temperature,

fluid not compatible

Revise working conditions

Body or flanges

break

Assembly bolts with counterflanges has been

wrongly tightened or counterflanges are

misaligned or with too much gap.

Weight not properly supported

Revise installation and tightening

according to this Manual

Working parameters beyond allowable limits

Replace by suitable valve

ATTENTION!

- It is essential that the safety regulations are observed when identifying faults.