MicroBlaster MB1006

Section 1: The MicroBlaster MB1006

Comco Inc.

1-3

Issue Date: September 2003

How the MicroBlaster Works

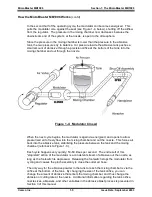

As shown in Figure 1-2, below, when the MicroBlaster Power Switch on the front panel is

initially turned “ON”, supply air enters through the energized air valve at the back of the

unit. The supply air passes through a regulator that allows the operator to control the

system pressure, as indicated by the gage on the front of the machine.

The regulated air then passes through an open, or de-energized, modulator assembly

and into the mixing chamber and abrasive tank (only one tank shown). Air cannot

escape through the nozzle because the hose pinch (or shut-off) assembly is closed. The

air pressure inside the system builds up until it reaches the regulated pressure.

Figure 1-2: MicroBlaster, Pressurized

The MicroBlaster, as shown in the illustration above, is now pressurized and ready to

use. To operate the MicroBlaster from this point would simply require picking up the

nozzle for the selected tank, pointing it at the item to be blasted, and depressing the

footswitch to begin blasting. What happens when the machine is actually in operation is

explained on the following pages.