7

Manual Set-Up

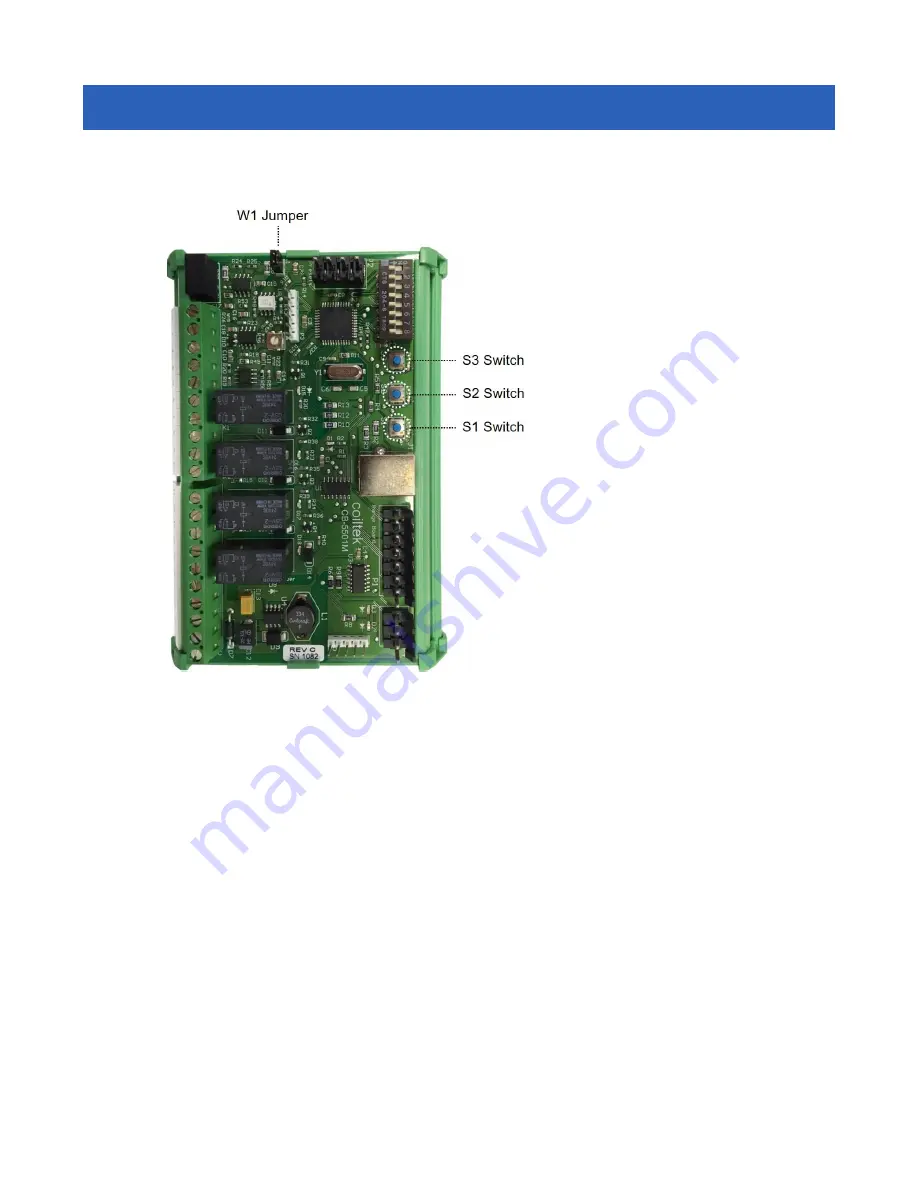

The CS-5000 is very easy to set up if the W1 jumper is in place. Here's how:

1.

Press button S1. Lights above

buttons S2 and S3 will begin

to

blink.

2.

Put a target beneath the sensor

(unless the product is very

narrow, say <3/4” wide, use

the material you're running).

Place it in the position farthest

from the sensor. It will be the

outer limit of your control

range. Press S3. The light

above S3 will stay on and stop

blinking.

3.

Place the same target at the

desired near point of the

control range. Press S2. If the

set-up is accepted, the lights

above S2 and S3 will go out

and the system will return to

run mode. Calibration is

complete.

Alternately:

1.

Press button S1. Lights above buttons S2 and S3 will begin to blink.

2.

Put a target beneath the sensor. Place it in the desired near position. It will be the upper

limit of your control range. Press S2. The light above S2 will stay on and stop blinking.

3.

Place the same target at the desired far point of the control range. Press S3. If the set-up is

accepted, the lights above S2 and S3 will go out and the system will return to run mode.

Calibration is complete.

As shipped, after performing the procedure above, signal output will be 0VDC (4mA) at the far point

and 10VDC (20mA) at the near point of the control range. This output may be used to control

upstream or process feeding devices. In order to control downstream processes, the signal must be

inverted. To do this, turn on DIP switch #7. If you remove jumper W1, your settings cannot be over-

written.

Содержание CS-5100 Series

Страница 11: ...11 Terminals and Inputs...