13

Throttle lever

Engine switch

8. Stopping

Move the throttle lever on the equipment to the fully

CLOSED (engine idle speed) position, and the

engine running at idle speed.

Turn the engine switch to the “O” (stopping) position.

Note:

Suddenly stopping engine from highspeed

operation can cause engine damage.

Reduce engine speed to idle speed for one minute

before shutting engine off after high-speed, full-load

operation.

Emergency Stop:

Turn the engine switch to the “O” (stopping) position.

Note:

-Never stop the engine by closing the choke lever.

-Never stop the engine during operation while

running above idle speed.

-Shut off the engine and allow it to cool before

transporting or storing the unit.

-Do not put the unit on dry grass or near any

flammable object unless the engine is cold or cooled

down.

9. Maintenance

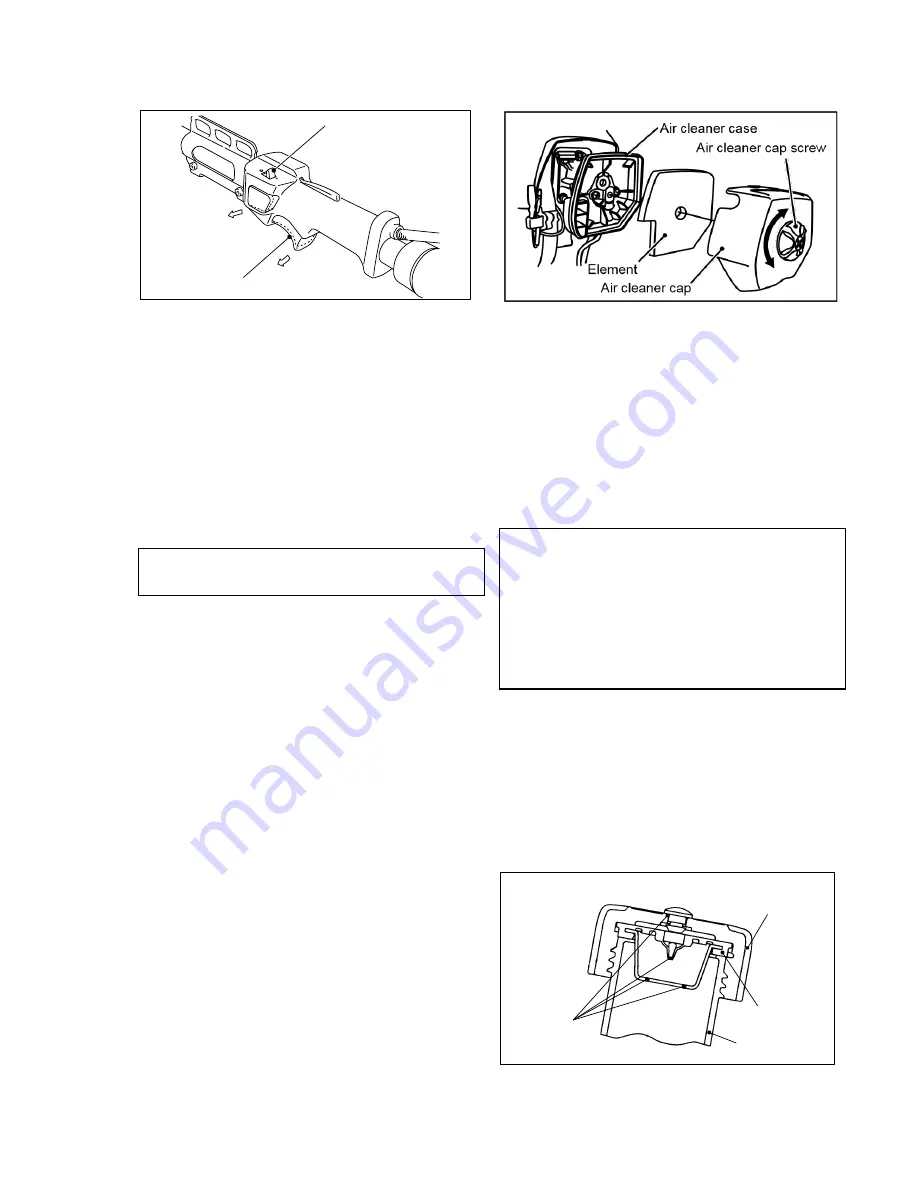

Air Cleaner Service

Clean the air cleaner element every 20 hours.

-Remove the air cleaner cap from the air cleaner

case by removing the air cleaner cap screw.

-Remove the element from the air cleaner case.

-Wash the element in detergent and water and dry it

thoroughly.

-Reinstall the element in the air cleaner case and

reinstall the air cleaner and tighten the screw.

Note:

Improper element cleaning can result in engine

damage.

Do not use compressed air to clean or dry element.

Always clean element with an approved high flash

point solvent only. Never use petrol.

Do not operate engine with air filter parts removed.

Fuel Tank Cap Service

A breather passage is incorporated in the tank cap.

If the breather passage is clogged, the fuel will not

flow into the carburettor, causing problems with

starting or running the engine.

At the same time, make sure that the base of the

breather assembly is fitted firmly into the groove

inside the tank cap as shown.

Breather

passage

Tank cap

Fuel tank

Breather

assembly