TO SAW

7. Lower blade using toggle switch (9) located in speed control handle (12), (follow instructions

on handle). Releasing switch will stop blade from lowering. Stop lowering when blade contacts

pavement. With the blade touching pavement, set cutting depth indicator (6) to zero, then

continue lowering until the desired cutting depth is shown on the cutting depth indicator.

8. To use depth stop control (5) turn handle clockwise until resistance is met. For greater depth

turn handle counter- clockwise, for lesser depth turn handle clockwise.

9. Move speed control handle (12) forward SLOWLY until proper cutting speed is achieved.

WHEN CUT IS FINISHED

1. Return speed control handle (12) back to neutral position.

2. Raise blade from cut by using the toggle switch (9) in speed control handle. When switch is

released the raise will stop and hold in place.

3. Once the blade is completely out of the cut turn off water to blade (11).

4.

Close throttle (8) to idle position. Let engine cool down before

stopping.

DO NOT STOP AT FULL THROTTLE!

NOTE: All sawing is done with engine at full throttle. Engine governor is factory set to achieve

proper blade speeds and engine performance. DO NOT CHANGE GOVERNOR SETTING unless

you are changing blade capacity (Diameter).

STRAIGHT LINE SAWING ADJUSTMENT

Your C65B is equipped with rear axle adjustment to adjust for blade lead off. The

adjustment nut is located at the back of the saw on the lower left frame. To adjust saw,

stop saw, stop forward drive, remove blade from cut and STOP ENGINE. Loosen rear

axle mount bolts on left rear of saw. If the saw is leading to the right, turn the adjustment

nut COUNTER-CLOCKWISE. If the saw is leading to the left turn the adjustment nut

CLOCKWISE. Retighten axle mount bolts securely after making adjustment.

DO NOT FORCE ADJUSTMENT

Содержание C65B

Страница 1: ...OWNER S MANUAL CONCRETE SAW MODEL C65B FORM 5313 12 03 01 ...

Страница 9: ...C65B MAIN FRAME GROUP ...

Страница 12: ......

Страница 14: ......

Страница 17: ...DEPTH STOP DEPTH INDICATOR FRONT AXLE GROUP DEPTH STOP DEPTH INDICATOR FRONT AXLE GROUP ...

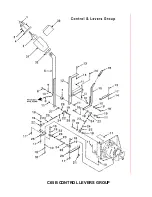

Страница 19: ...C65B CONTROL LEVERS GROUP ...

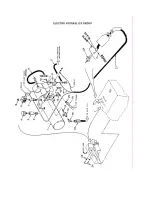

Страница 21: ......

Страница 23: ...C65B PARTS LIST BLADE SHAFT DRIVES GROUP ITEM DESCRIPTION PART NO ITEM DESCRIPTION PART NO ...

Страница 25: ......

Страница 27: ......

Страница 29: ......

Страница 31: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 39: ...NOTES ...