Page 5

823036EN

02/11/2014

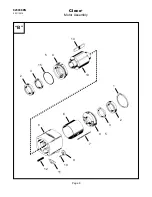

Invert the motor housing and install the rotor with the

end stamped “REAR” into the rear rotor bearing.

Insert the six (6) rotor blades into the rotor. Lubricate

the o-rings on the front bearing plate and press this

assembly into the motor housing.

Note: Make sure the

o-ring (863096) is installed on the front bearing plate.

Impact Mechanism Assembly:

Put a light coating of 30W oil on all parts before

assembling.

Insert the timing pin into the recess located on the small

O.D. of the cam. Install the cam and pin into the rear of

the hammer.

Install the cam roller shaft into the cam shaft and slide

the cam roller over the cam roller shaft. Place the butt

plate, insulator and shock absorber onto the rear of the

cam shaft.

Hold the cam shaft vertically on the work bench with

the shock absorber down and tap the end of the cam

shaft with a soft mallet to seat the cam shaft in the shock

absorber. Insert the cam shaft assembly through the

cam and hammer assembly.

Install the hammer spring, anvil pin and spring clip onto

the front of the cam shaft and hammer assembly. Rotate

the spring clip to accept the anvil pin and then install the

anvil on top of the assembly. Make sure the slot in the

anvil lines up with the anvil pin. Drive the anvil down until

the spring clip engages the recess in the anvil.

Spline Drive Models: Insert the socket retainer spring

and socket retainer plunger into the anvil and then drive

the socket retainer pin radially into the plunger.

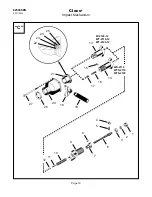

Anvil Housing Assembly:

If the anvil housing bushing requires replacement it

should be pressed in as shown below.

General Assembly:

Put a light coating of 30W oil on the hammer and rotor

splines. Insert the impact mechanism into the front of the

rotor. Lubricate the anvil housing seal and bushing with

30W oil and install on the unit. Make sure the contour of

the anvil housing matches the motor housing.

The anvil and hammer lugs should be in line with the

recess in the make-up lip located in the anvil housing.

Install the dead handle bracket on the left side of the tool

and insert the four housing bolts. Lightly tap the bolts

with a hammer until the anvil housing seats against the

motor housing.

Clamp the tool vertically in a smooth jawed vise and

install the gasket. Insert the o-ring (847981) into the

reversing valve bore and install the reversing valve.

Apply a thin coating of grease to the motor clamp seal

(869001) and place it into the handle recess.

Assemble the handle to the tool using the four (4) nuts.

Tighten the nuts to 20 ft. lbs. torque.

Lay the tool on its right side and remove the 30W oil fill

plug. Fill the reservoir with a good grade of 30W oil up to

the level of the fill indicator pin located in the reservoir,

approximately 1 to 1.25 fluid ounces.

Place a couple of teaspoons of 10W machine oil in the

air inlet bushing before attaching the air hose. This will

insure immediate lubrication of all motor components.

Disposal:

Observe local disposal guidelines for all

components of this tool and its packaging.

Copyright Protection:

Apex Tool Group, LLC or Apex Tool Group GmbH &

Co. OHG reserves the right to modify, supplement or

improve this document or the product without prior

notice. This document may not be reproduced in any

way, shape or form, in full or parts thereof, or copied to

another natural or machine readable language or to a

data carrier, whether electronic, mechanical, optical or

otherwise without the express permission of Apex Tool

Group, LLC or Apex Tool Group GmbH & Co. OHG

Press on this O.D. only

Press on this O.D. only

Cleco

®

Product Information