General Troubleshooting Guide

1

ClearWater Tech, LLC.

Toll Free: 1.800.262.0203 • Ph: 805.549.9724 • Fax: 805.549.0306

850-E Capitolio Way, San Luis Obispo, CA 93401 • email: [email protected] • www.cwtozone.com 110613

This guide goes over the standard troubleshooting that is performed during periodic check-ups on a system or if it is suspected of not performing

properly. The installation of a gauge assembly on the system makes this much easier.

To have the expected amount of ozone oxidizing the water, four basic factors have to be taken into account. If one of these is not working properly it

will result in a reduced amount of ozone oxidizing the water, and thus low ORP and ozone ppm readings.

•

The ozone generator

has to produce ozone

•

The air preparation system

has to be functional

o

An air dryer should dry the air

o

An oxygen concentrator should both dry the air and produce 90% oxygen

•

No air leaks

should be present in the airlines, this will insure the gas we’re introducing into the water is in fact ozone.

•

The water

itself has to have the correct properties to allow the ozone to oxidize properly

The Ozone Generator

In all of our systems there is a display light of some kind that you typically see during ozone production. If it is illuminated, we can expect ozone is

being generated; the cause for any reduction in ozone output will likely be found in the other three sections of this guide.

All of our corona discharge ozone generators are "all-or-nothing" type systems.

There are enough diagnostics built in to most systems that will disable the “ozone” light if there is an issue.

If the output light is not illuminated, the generator is not producing ozone and the ozone generator should be investigated. Consult the ozone

generators manual and any support documents.

Verify ozone generation

by detecting the scent of ozone anywhere in the installation (e.g. the tubing connection on the contact tank’s off-gas vent).

Due to the ozone generator being “all-or-nothing” if some ozone is detected, we know that the reaction chamber and related circuitry is operational.

If we cannot detect ozone in an easy fashion, we can test the ozone generator directly by

blowing air through it:

•

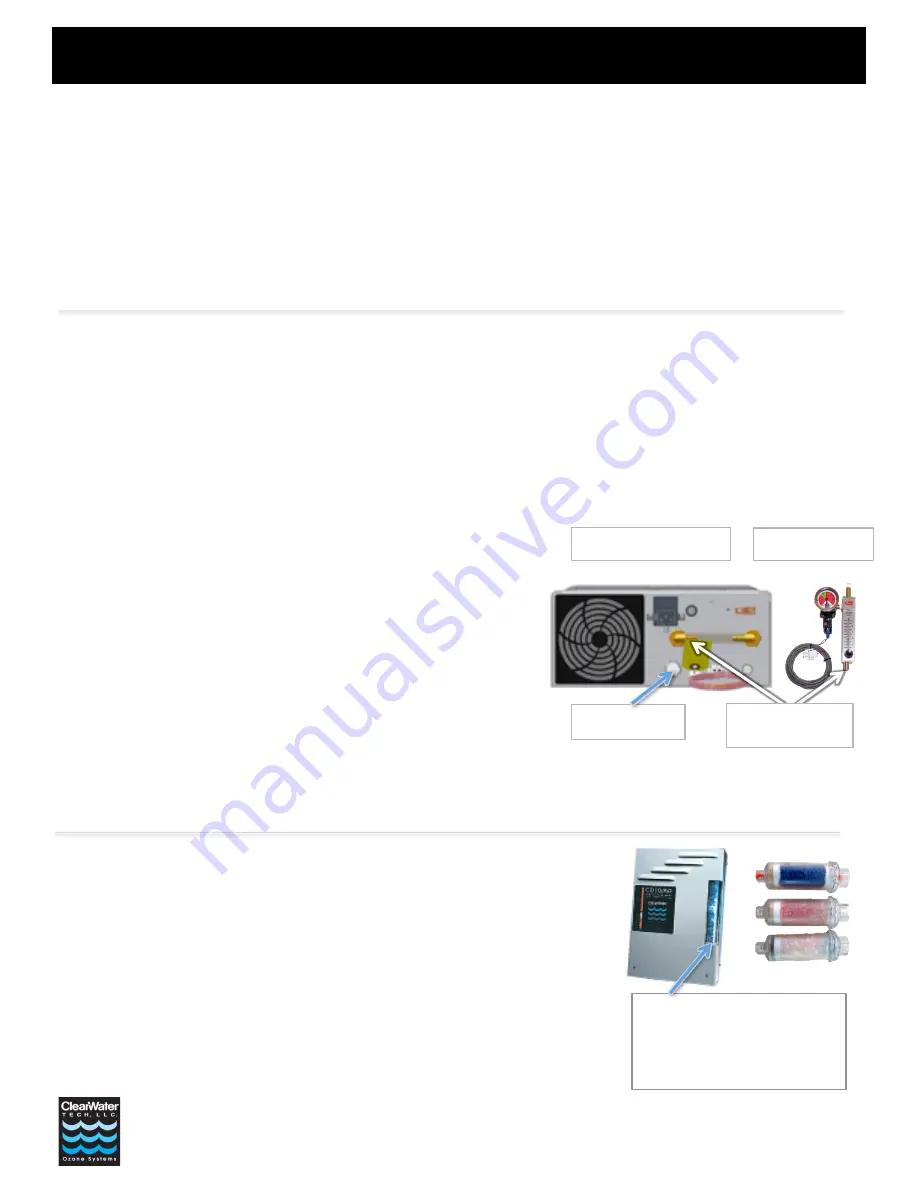

Disconnect tubing from the underside of the air inlet of the ozone generator; the intention

is to blow air into this fitting.

o

A common location is the underside of the airflow (SCFH) gauge mounted on the

underside of the ozone generator.

o

If no gauge is installed, it will be a brass connection on the underside of the

ozone generator, in an ozone model number that ends in “/AD” it will be the left-

side brass connection we are interested in.

•

Disconnect the ozone outlet of the ozone generator.

o

This is a stainless steel fitting, commonly with a grey check valve installed in this

port. Remove the check valve, as blowing air through it can be difficult.

•

Apply power, enable ozone output and allow it to run for 30 seconds

•

Cup your hand around the ozone outlet fitting and flow air into the brass inlet

•

Detect the scent of ozone in your hand

o

The smell of ozone is sharp, sweet and can be smelled after a thunderstorm, it is often described as similar to chlorine bleach.

o

If ozone is detected, then the generator is working.

o

If there is no scent of ozone, note down all display lights, gauge readings. Write down the model and serial number of the unit, consult the

manual or contact your distributor or ClearWater Tech to continue troubleshooting.

Air Preparation

Blue silica gel crystals are installed in each model ozone generator. Some models have a chamber

visible through the cover that has mixed blue and white crystals. This is at times referred to as

indicating desiccant media.

Ozone generators need to be supplied with dried air or oxygen to produce the expected amount of

ozone. Ozone generators with model numbers that end in “/AD” have internal air dryers for this

purpose. Other models are commonly paired with oxygen concentrators.

The color of the crystals serves as a status check on the air supplying the ozone generator. There should

be no moisture present in the output of an air dryer or oxygen concentrator.

Any moisture passing through the crystals will be absorbed by the silica and produce a color change of

blue, to pink and finally to white.

Ozone out here

Flow air into one

of these two points

Gauge assembly

Underside of a CD12/AD

Inline particulate filters and

indicating chamber within a unit

The original blue and two colors

that indicate a nonfunctioning air

preparation system