OH 6302BL

TROLLEY JACK 2T

MAINTENANCE

TROUBLESHOOTING

• When the vehicle jack is not in use, the lifting arm must be in the lowest position and the handle in

a vertical position so as not to interfere.

• The jack must be stored in a horizontal position and in a dry place. Make sure that the jack remains

in its original condition. Do not make any modifi cations to the appliance.

• Only use special quality hydraulic oil for the pump. Properly dispose of any old or spilled oil.

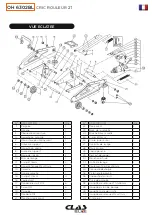

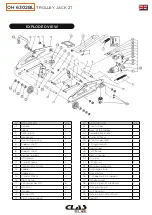

• Do not use a high-pressure cleaner to clean the jack. All external moving parts, e.g. bearings (5),

lift arm fi xing bolts (6), lift arm cylinder fi xing bolts (7) and pump arm fi xing bolts (8) must be

lubricated regularly every 3 months.

IMPORTANT: Never lubricate or grease the rods of the pump (9) and the lift cylinder (10).

• All maintenance and repair work must be carried out by suitably qualifi ed personnel in accordance

with the manufacturer's instructions.

• Caution: Do not use the jack if any parts are missing, loose or broken (risk of accident!).

NOTE: The instructions below should not be carried out when the jack is in use.

NOTE: The vehicle jack is equipped with a safety valve (15). It has been confi gured to allow the jack

to lift loads up to 2 tons. The safety valve must not be altered or adjusted in any way!

Problem 1: The lifting arm does not lift when pumping under load

- Check that the drain valve is completely closed. Close it by turning the handle clockwise.

- Check the oil level by placing the vehicle jack in the horizontal position.

- There is not enough oil. Top up the hydraulic oil and bleed the hydraulic system.

Problem 2: The lift arm sinks under the load

- Follow the instructions provided for "Problem 1". If this does not eliminate the fault, the vehicle

jack must be repaired by an authorised repairer.

Problem 3: The lift arm cannot be lowered

- The lift arm tension spring has come loose or broken. Unhook the spring or replace the broken

spring with a new equivalent spring.

- The vehicle jack probably needs to be lubricated. All moving parts should be cleaned and

lubricated or greased. IMPORTANT: The rods of the pumping and lifting cylinder must never be

lubricated or greased.

- Too much oil in the hydraulic system. Unscrew the drain valve and drain off the excess oil.