Page 12

Clarke

®

American Sanders

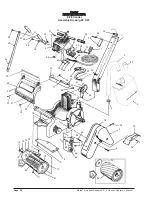

EZ - 8 Sander Operator's Manual

Routine Maintenance

The following items need to be periodically inspected

and maintained to keep your sander in good working

condition.

Sanding Chamber

Periodically blow out the sanding chamber to prevent

large accumulations of debris which could interfere

with the performance of the dust recovery system.

Wheels

Periodically remove the debris from the truck and

caster wheels. Debris can cause waves on a sanded

surface.

Dust Bag

Remove the dust bag from the machine and shake it

thoroughly to remove the sanding dust from the dust

bag. Turn the dust bag inside out and machine wash

in cold water to prevent pore blockage and loss of

dust recovery.

Drive Belt

Periodically check the drive belts for broken cogs or

frayed edges. Frayed edges may indicate poor

tracking. Realign effected belt.

Bearings

Periodically check the bearings for wear or

damage according to the following schedule:

Arbor shaft

Relubricate every 150 hrs.

w/.10 oz. of a NLGI grade

2, -30

0

F to 250

0

F, 58-75

SUS at 210

0

F, grease

lubricant.

Motor shaft

after 1

st

5000 hrs.

Fan shaft

After first 1500 hrs.