Installation

CAUTION

Your compressor is heavy,take care when moving or transporting it.

•

Locate the compressor on a firm, flat, level surface, in a dry and dust free

area. Do not use the compressor in a damp or wet environment.

•

The compressor must have adequate ventilation to allow a fresh air intake to

the compressor and cooling air to the motor.

•

Ensure that the air available to the compressor is as clean as possible.

Dusty or damp air at the inlet will reduce the compressor’s performance and

affect the quality of air supplied to your tools.

•

Do not place any strain on electrical cables or air hoses connected to the

compressor.

Starting the compressor

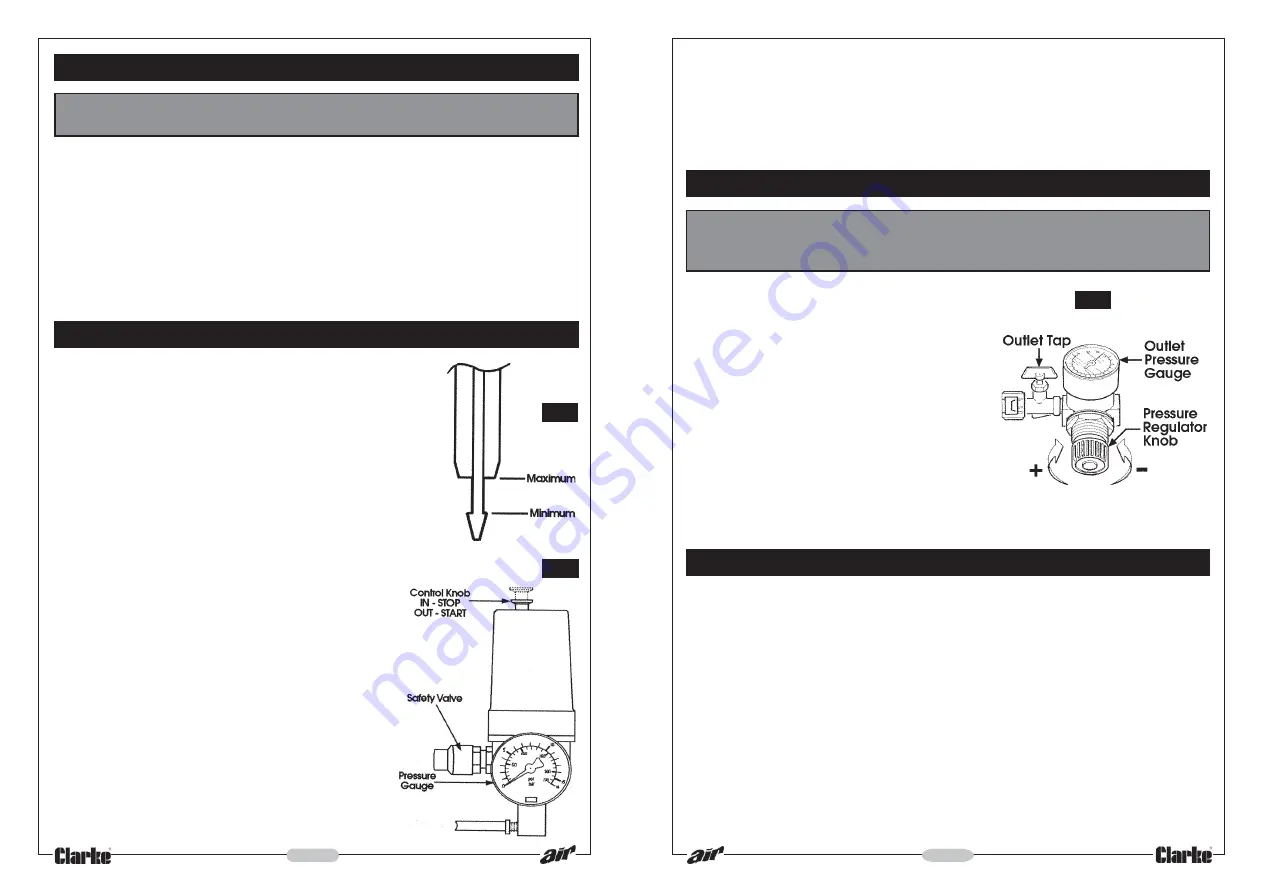

Before starting the compressor, check the oil level, and

top up if necessary with Clarke SAE 40 compressor oil.

The oil level should be between the minimum and

maximum marks on the dipstick (see figure 2).

Note: The compressor has an automatic pressure switch

which will start the compressor when the air pressure in

the receiver is low, and stop the compressor when the

air receiver is at its maximum pressure. This switch also

controls a breather valve which vents the compressor

outlet when the compresor stops, to prevent overloading

the motor when restarting.

Never switch the compressor on or off using the mains switch

.

Always use the control knob on the automatic pressure switch.

1.

Make sure the control knob on the automatic

pressure switch is in the OFF (‘0’) position (control

knob pushed in - see figure 3).

2.

Switch on the mains supply.

3.

Lift the control knob on the automatic pressure

switch to the ON (‘I’) position. The motor should

start immediately. If it does not, it may be

because the air receiver is already up to

pressure. Check the tank pressure gauge and

release some air by opening the outlet valve if

necessary.

4.

Run the compressor with the outlet valve open

for a few moments. This allows the compressor

lubricating oil to circulate before the compressor

is placed under load.

6

5.

Close the outlet valve, and allow the pressure in the receiver to rise before

connecting your air hose and tools to the compressor.

Note: The compressor should start and stop automatically as air is used from the receiver. If

the compressor runs continuously it may be because the compressor is too small for your

application. Consult your dealer for advice.

Adjusting the air pressure

CAUTION!

Always follow the air tool manufacturer’s guidelines on the maximum

operating pressure for their equipment.

The pressure in the air receiver is controlled by

the automatic pressure switch. You can control

the pressure supplied to your air hose and tools

by adjusting the outlet pressure regulator (see

figure 4). Turn the pressure regulator knob

clockwise to increase the pressure and anti-

clockwise to decrease.

As a rough guide to operating pressure, Clarke

paint spray guns typically operate at between

30 and 60 psi (approximately 2 to 4 bar). Most

Clarke air tools operate at around 90 psi

(approximately 6 bar), but if in any doubt about

operating pressure consult the equipment

manufacturer.

Stopping the compressor

1.

Push in the control knob on the automatic pressure switch, to the OFF(‘0’)

position. This will open the breather valve and stop the compressor. You may

hear a release of air as the breather valve opens.

2.

Switch off and unplug from the mains supply.

If the compressor is not going to be used for some time, for example overnight,

or if you are transporting the compressor, drain the air from the receiver.

7

Fig.4

Fig.3

Fig.2