Planned Maintenance and Lubrication

6.9

Battery Handling

1. Change (remove) or service storage batteries only in an area des

-

ignated for this purpose.

2. Be sure this area has provisions to flush and neutralize spillage, to

ventilate fumes from gassing batteries, and for fire protection.

3. This area should be equipped with material handling tools designed

for removing and replacing batteries, including a conveyor or over-

head hoist. Use lift hooks that have safety latches.

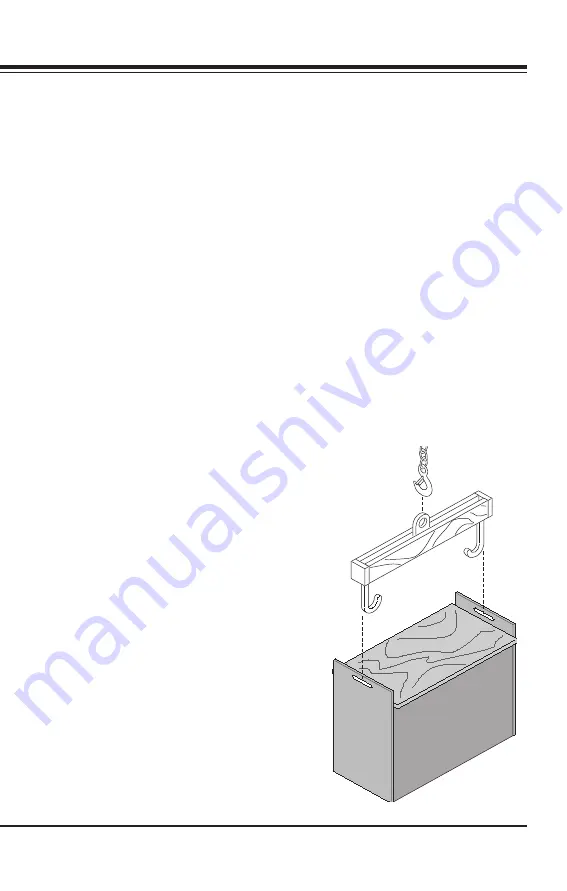

4. Always use a special lifting device such as an insulted spreader

bar to attach the hoist to the battery. The width of the spreader bar

must be the same as the lifting eyes of the battery, to prevent dam-

age to the battery. If the spreader bar hooks are movable, carefully

adjust the position (width) of the hooks so that the pull is directly

upward (vertical) and no side load or force (pressure) is exerted

on the battery case. Be sure the lift hooks are the correct size to

fit the lifting eyes of the battery.

5. If the battery does not have a cover

of its own or has exposed terminals

and connectors, cover the top with

a non-conductive (insulating) ma

-

terial, such as a sheet of plywood or

heavy cardboard, prior to attaching

the lifting device.

Содержание WSRX 30

Страница 6: ...iv...

Страница 30: ...2 8...

Страница 44: ...4 6 Operator Maintenance and Care...

Страница 72: ...Planned Maintenance and Lubrication 6 14...

Страница 74: ...7 2...

Страница 76: ...8 2...