Page 5

INSTALLATION

SET UP

: Set unit in position and fasten securely to board. Slip support spring in position and fasten with set screw. Fasten iron

rest to board.

IMPORTANT

: Before making steam return connections to unit, make steam supply connections. Remove all drain plugs, open

steam supply globe valve to steam-flush any borings, grindings or foreign matter that may be clinging within casting or pipes. Close

globe valve; replace drain plugs and make steam return connections.

Before attaching steam hose from steam-electric iron to solenoid valve, with steam pressure on unit operate thumb switch several

times to remove loose particles of scale dirt, which may become embedded in valve seat. Then fasten steam hose to solenoid valve.

STEAM SUPPLY

: Steam supply connection must fall towards machine (without water pockets). Make connection with 12 or more

riser out of steam supply line with union and globe valve. (NOTE: If machine is on the end of a line of equipment, then extend

steam header line at least four feet beyond machine. Install check valve and trap at end of line. If gravity return omit trap.)

STEAM RETURN

: If steam is returned to atmosphere or sewer, make steam return connection with union, globe valve, check

valve and trap with drain. If steam is gravity returned to boiler, omit trap, but install trap as close to floor and as near machine as

possible. Inspect traps carefully for inlet and outlet marks and install according to factory instruction. BLOW SCALE AND DIRT

FROM STEAM LINES BEFORE INSTALLING TRAP TO INSURE PROPER OPERATION.)

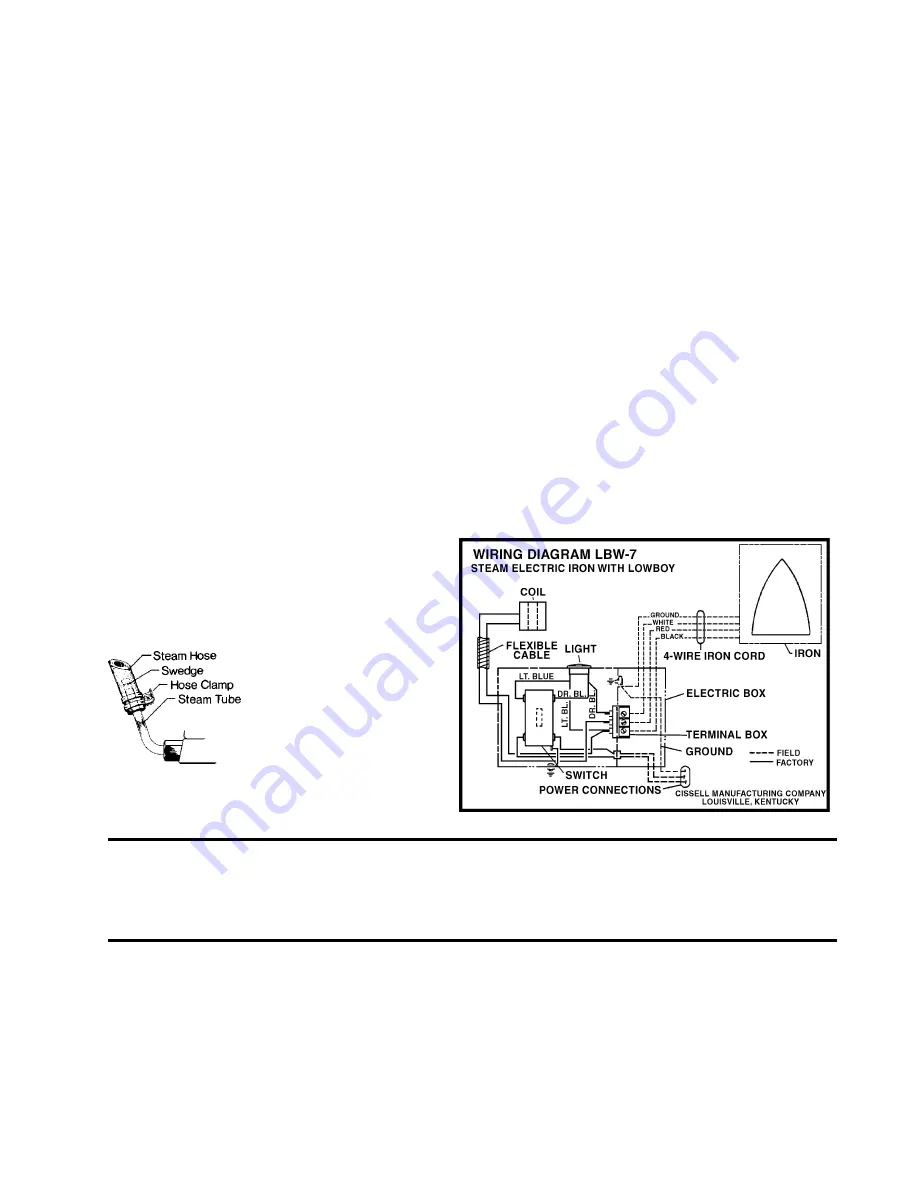

WIRING

: Check Voltage and current of solenoid valve and

see that they correspond with power line before making

installation. Use irons with properly rated thumb switch.

NOTE

: Connect power supply to terminals in electric box

as per wiring diagram in accordance with electric code in

your area.

FOR THREE PHASE CURRENT

: Connect two wires

from three phase supply to two Power Connections of outlet

box.

IMPORTANT

: Connect ground wire as shown and check

all wiring before closing switch.

MECHANICAL SPECIFICATIONS

Boiler Horsepower - Approximately 1/8.

Operating Steam Pressure - 5 to 100 lbs.

Steam Supply - 1/2 Pipe Connection.

Steam Return - 1/2 Pipe Connection.

IMPORTANT

Attach Steam Hose to Steam Tube as

illustrated. Push Steam Hose down on

Steam Tube just far enough beyond

swedge to allow Hose clamp

connection. Do not push Steam Hose

all the way down on Steam Tube as

this will cause hose to burn out.

MECHANICAL OPERATION

Place iron on rest. Turn toggle switch on (pilot light indicates

when current is on); allow iron to heat, set indicator to Rayon

Open steam supply and return valves. A cold iron will throw

water. Wait until iron becomes hot then push electric thumb

switch of iron to allow steam to flow from soleplate of iron.

Release thumb switch to stop steam flow. Screw valve knob in

for less steam, out for more.

MECHANICAL MAINTENANCE

To replace coil in solenoid valve, remove bolt, cover, leaf spring,

insulating washer and coil. Install new coil and replace washer,

spring, cover and bolt. Solenoid valve is packless. To replace

renewable valve seat or plunger, unscrew large hex nut from

lower cast body. Coil or solenoid valve is constructed of heat

resisting materials. When ordering new coil, specify voltage

and current, giving frequency of power line. Example: 120

Volt, 60 cycle, A.C.