CS2200-CP

DS759F3

17

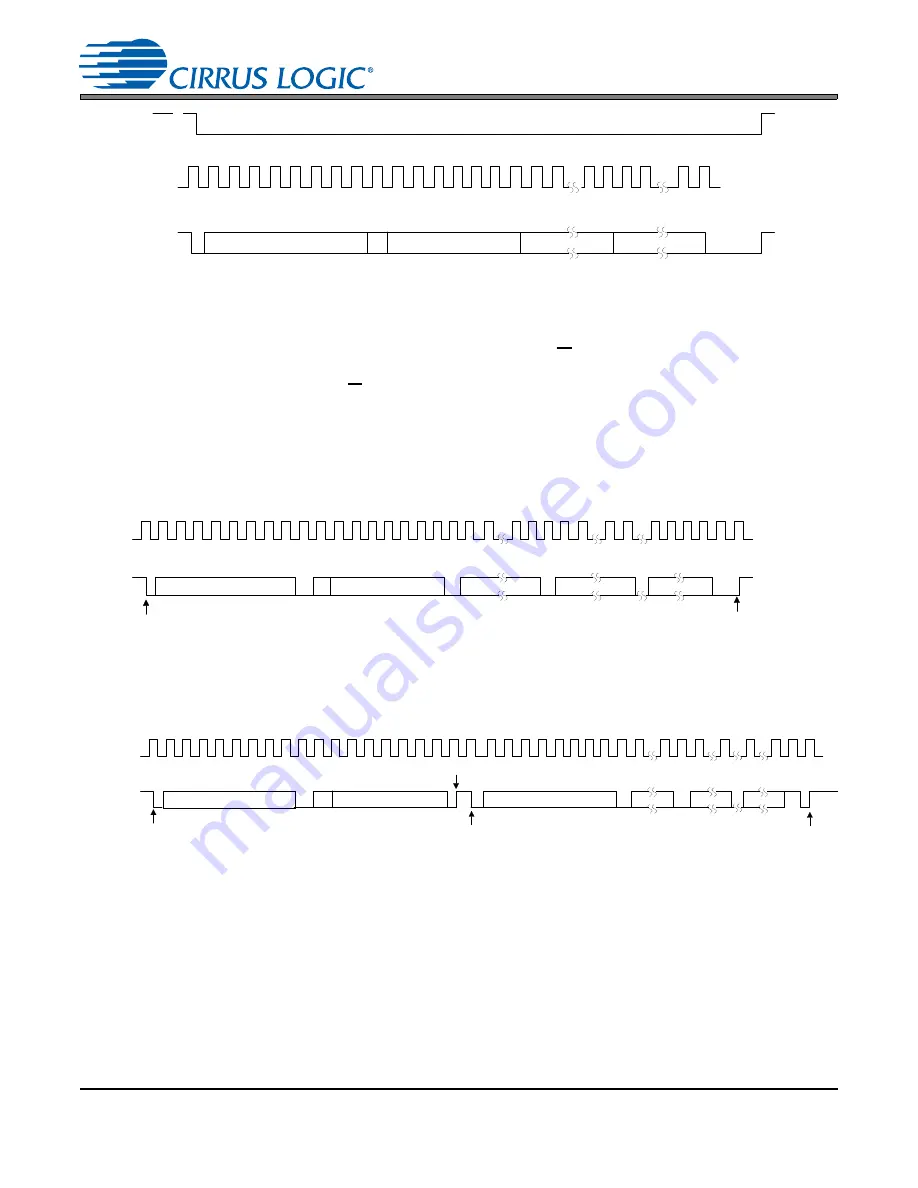

The signal timings for a read and write cycle are shown in

and

. A Start condition is de-

fined as a falling transition of SDA while the clock is high. A Stop condition is a rising transition while the

clock is high. All other transitions of SDA occur while the clock is low. The first byte sent to the

CS2200

after

a Start condition consists of the 7-bit chip address field and a R/W bit (high for a read, low for a write). The

upper 6 bits of the 7-bit address field are fixed at 100111 followed by the logic state of the AD0 pin. The

eighth bit of the address is the R/W bit. If the operation is a write, the next byte is the Memory Address Point-

er (MAP) which selects the register to be read or written. If the operation is a read, the contents of the reg-

ister pointed to by the MAP will be output. Setting the auto increment bit in MAP allows successive reads or

writes of consecutive registers. Each byte is separated by an acknowledge bit. The ACK bit is output from

the

CS2200

after each input byte is read and is input from the microcontroller after each transmitted byte.

Since the read operation cannot set the MAP, an aborted write operation is used as a preamble. As shown

in

, the write operation is aborted after the acknowledge for the MAP byte by sending a stop con-

dition. The following pseudocode illustrates an aborted write operation followed by a read operation.

Send start condition.

Send 100111x0 (chip address & write operation).

Receive acknowledge bit.

Send MAP byte, auto increment off.

Receive acknowledge bit.

4 5 6 7

CCLK

CHIP ADDRESS

MAP BYTE

DATA

1 0 0 1 1 1 1 0

CDIN

INCR

6 5 4 3 2 1 0 7 6 1 0

0 1 2 3

8 9

12

16 17

10 11

13 14 15

DATA +n

CS

7 6 1 0

Figure 11. Control Port Timing in SPI Mode

4 5 6 7

24 25

SCL

CHIP ADDRESS (WRITE)

MAP BYTE

DATA

DATA +1

START

ACK

STOP

ACK

ACK

ACK

1 0 0 1 1 1 AD0 0

SDA

INCR

6 5 4 3 2 1 0

7 6 1 0

7 6 1 0

7 6 1 0

0 1 2 3

8 9

12

16 17 18 19

10 11

13 14 15

27 28

26

DATA +n

Figure 12. Control Port Timing, I²C Write

SCL

CHIP ADDRESS (WRITE)

MAP BYTE

DATA

DATA +1

START

ACK

STOP

ACK

ACK

ACK

1 0 0 1 1 1 AD0 0

SDA

1 0 0 1 1 1 AD0 1

CHIP ADDRESS (READ)

START

INCR

6 5 4 3 2 1 0

7 0

7 0

7 0

NO

16

8 9

12 13 14 15

4 5 6 7

0 1

20 21 22 23 24

26 27 28

2 3

10 11

17 18 19

25

ACK

DATA + n

STOP

Figure 13. Control Port Timing, I²C Aborted Write + Read