INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accor-

dance with the National Electrical Code, NFPA 70.

1.

Before installing, unpack and check your TM series immersion

heater for any damage that may have occurred during shipment.

Report any claims to you carrier if damage has ocurred in ship-

ment.

Do not operate damaged equipment. Consult

factory for instructions.

2.

Check to ensure that the line voltage is the same as that stamped

on the nameplate. Verify wattage and capacity versus the require-

ments at installation site.

3.

Do not bend the heating elements. If bending is necessary,

consult factory.

4. IMPORTANT:

Mount the heater in the tank so that the liquid

level will always be above the effective heated portion of the

heater. If the heater is not properly submerged, it may overheat and

damage the heating elements (see Figure 1).

FIRE HAZARD. If the heater is not properly sub-

merged, the heating elements will overheat and could

result in a fire or damaged equipment.

5.

Where work will pass over or near equipment, additional protec-

tion such as a metal guard may be needed.

6.

Heater must not be operated in sludge.

7.

The gasket surface must be clean and dry before the heater is seat-

ed (see Figure 2).

8.

Closed Tank Installation

Note:

When heating in closed vessels, controls and

back-up controls must be used to prevent buildup of temper-

ature and/or pressure.

A. Horizontal Position (Figure 3)

A1.

Place heater at an elevation so that natural circulation can

take place.

A2.

Position outlet and inlet in a vertical plane, facing upward

to prevent air pockets. Be sure all trapped air is removed from

the closed tank. Bleed the air out of the liquid piping system

and heater enclosure prior to operation.

A3. IMPORTANT:

Heater should never be located at the

highest point of the water system. Provide expansion tank

if necessary.

A4.

Heaters shall be supported if the immersion length is greater

than 36”.

B. Vertical Position (Figure 4)

9.

A drip loop is recommended to minimize passage of moisture

from condensation along wiring into terminal box enclosure and

connections.

FIRE HAZARD. Since heaters are capable of developing

high temperatures, extreme care should be taken to:

A.

Use explosion-resistant terminal enclosures in hazardous loca-

tions. See Chromalox catalog for selection of explosion-resis-

tant terminal enclosure for hazardous locations.

B.

Avoid contact between heater and combustible materials.

C.

Keep combustible materials far enough away to be free of the

effects of high temperatures.

FREEZE HAZARD. This unit may be equipped with a

thermowell for process control or over-temperature

control. Do not allow moisture to accumulate in ther-

mowell. Freezing temperatures can cause damage

that may result in the heated medium leaking into ter-

minal enclosure.

Note:

Locate Heater as low as possible for maximum heated liquid storage capac-

ity. Heat does not move downward.

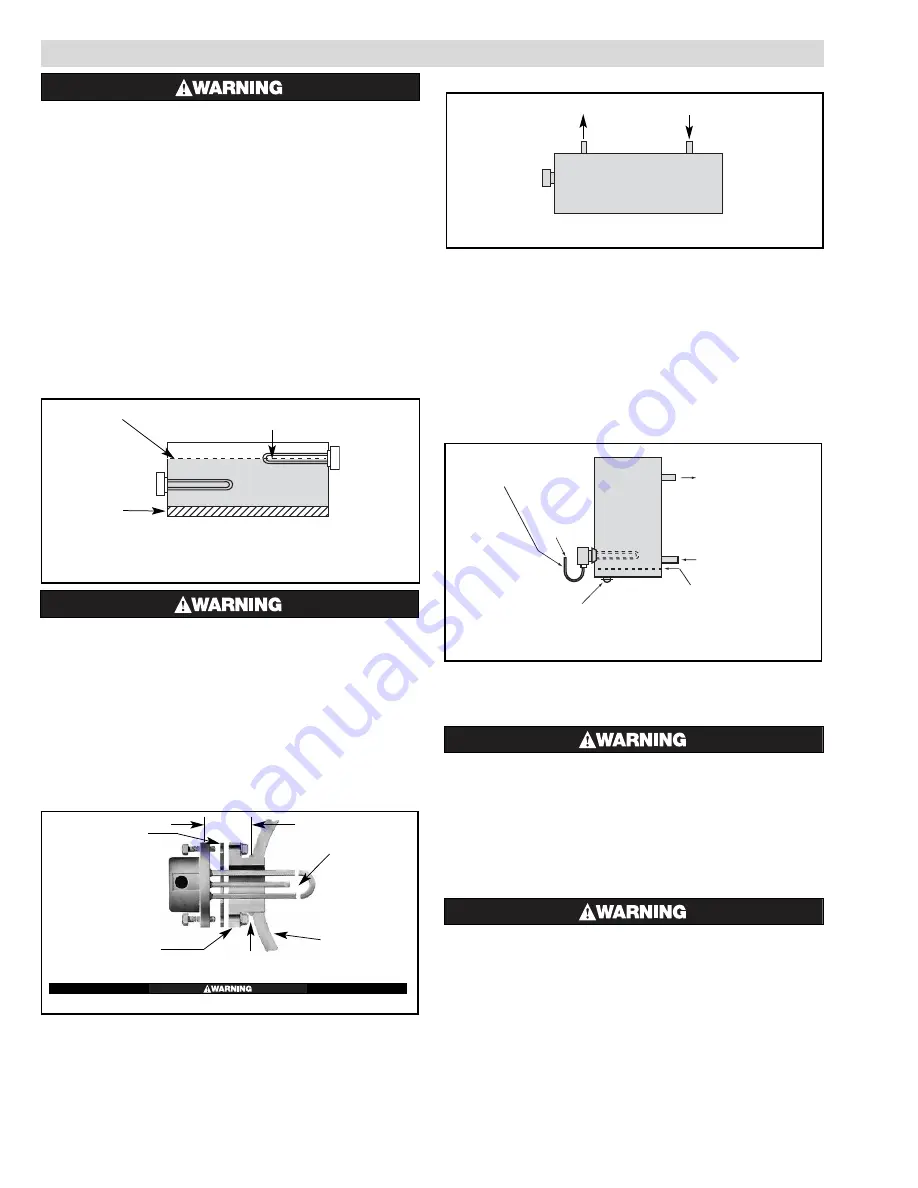

Figure 1 - Open Tank Installation

Expected Low Liquid

Level

This Portion of the Heater Above Liquid Level and

Exposed to Air Will Lead to Premature Failure of Element

Expected Maximum

Sediment Level

Figure 2 - Flanged Mounting

Care must be taken to ensure the heated portion does not extend into the coupling area.

Gasket

Cold End (See Warning)

Element

Tank

Wall

Standard

Pipe Flange

Weld

Locate Drain Pipe at Bottom of Heater,

Sediment Deposits may be

Removed Through Drain Pipe

Maximum Sediment Level.

Install Heater

Above

This Level But As

Near to it as Possible for Maximum

Heated Liquid Storage Capacity

Suitable

Wiring

Drip Loop Recommended

to Minimize Passage of Moisture

Along Wiring Into Terminal

Wiring and Connections

Outlet

Inlet

Figure 4 - Closed Tank in Vertical Position

Heater

Outlet

Inlet

Note: In A Forced Circulation System, Use Pump In Inlet Side.

Figure 3 Closed Tank in Horizontal Position

2