Page 10

For technical questions, please call 1-800-444-3353.

SKU 45689

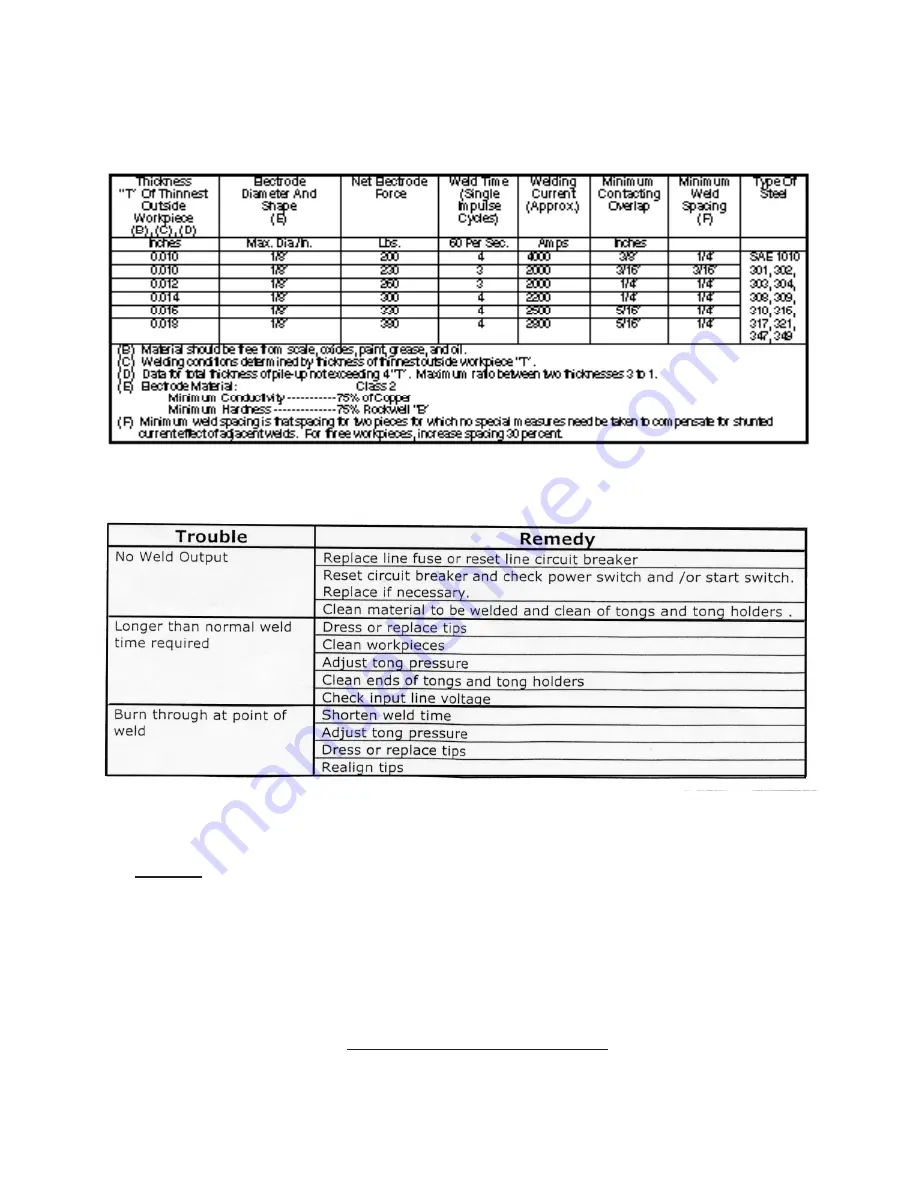

recoMMended practiceS

For Spot Welding loW-carBon Steel

trouBle Shooting guide

inSpection, Maintenance, and cleaning

1.

Caution:

Always disconnect the Spot Welder from its electrical power supply source

before performing any inspection, maintenance, or cleaning.

2.

Before each use, inspect the general condition of the Spot Welder. Inspect switch,

power plug and cord assembly, and extension cord (if used) for damage. Check for

loose screws, misalignment, binding of moving parts, broken parts and any other condi-

tion that may affect its safe operation. If abnormal noise or vibration occurs, disconnect

the Spot Welder from its electrical supply source immediately and have the problem cor-

rected before further use. Do not use damaged equipment.