25

IMPOR

TANT:

If the appliance is being converted from natural gas to propane (LPG), the following

operations must be performed before calibrating the gas valve as instructed above.

• Turn adjuster screw (V) on the gas valve clockwise through the number of complete revolutions

specified in table 3.

To simplify calibration of the gas valve, the “calibration function” can be set directly on the boiler

control panel by proceeding as follows:

1) Press the

keys (2-3) together until the display shows the pointer “ ” alongside the

symbol (about 6 seconds).

2) Press the

keys to set the fan speed at the minimum and maximum heat output

(%PWM);

N.b - to set the

minimum

and

maximum

heat output quickly, press the

keys respecti-

vely;

3) press either of the two

keys to exit the function.

0307_2201

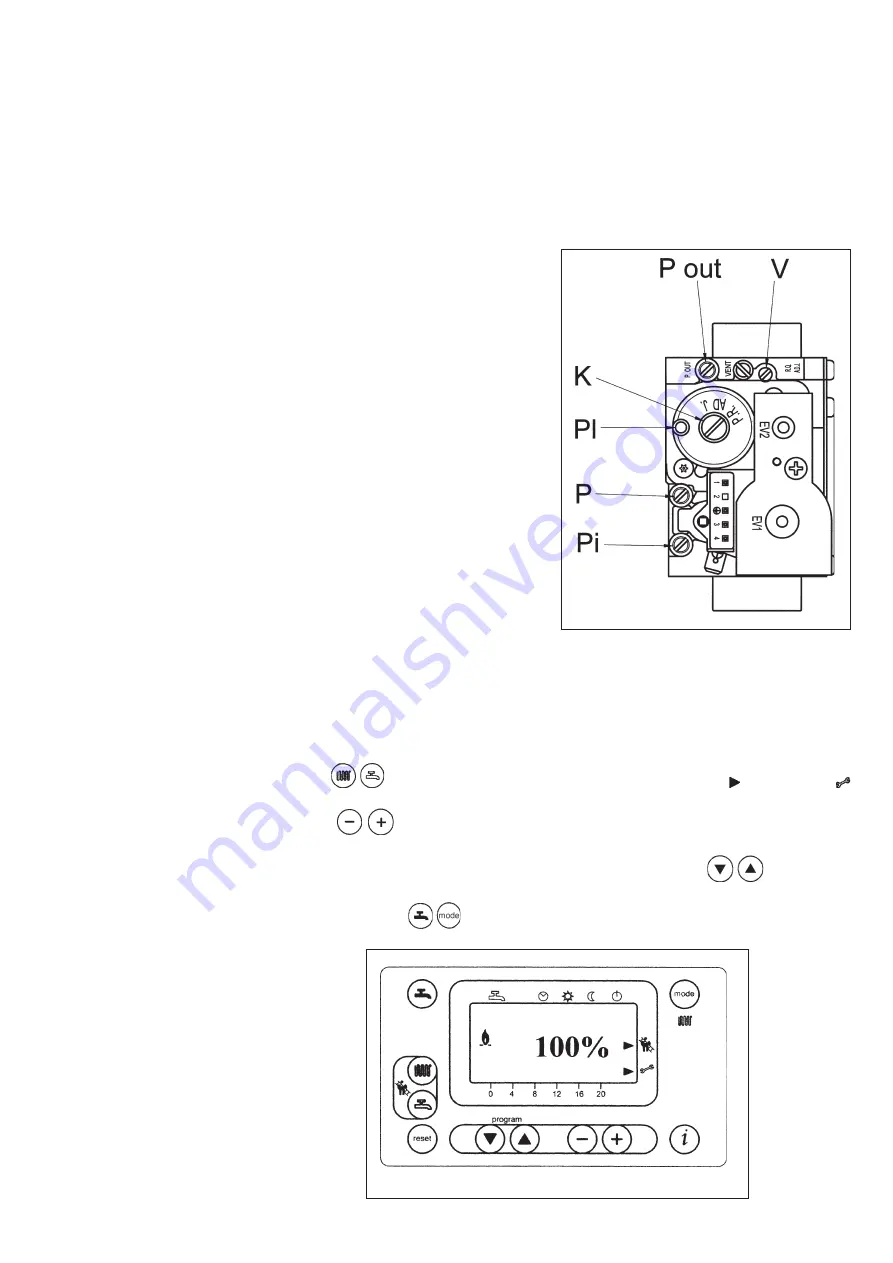

Figure 14

0310_01

14

Figure 13

Pi:

Gas supply pressure connection point

P out:

Gas pressure to burner connection point

P:

Pressure connection point

for measurement of the OFFSET

Pl:

Air signal input from fan

V:

Gas flow adjuster screw

K:

OFFSET adjuster screw

Carry out the following operations in the given sequence:

1)

Calibration of the maximum heat output. Check that the CO

2

measured on the flue, with the boiler

operating at the maximum heat output, is the same as that shown in table 1. Otherwise, turn the

regulation screw (V) on the gas valve. Turn the screw clockwise to reduce the concentration of

CO

2

and anticlockwise to increase it.

2)

Calibration of reduced heat output. Check that the CO

2

measured on the flue, with the boiler ope-

rating at the minimum heat output, is the same as that shown in table 1. Otherwise, turn the offset

regulation screw (K) on the gas valve. Turn the screw clockwise to increase the concentration of

CO

2

and anticlockwise to reduce it.

14. Gas valve adjustment