9

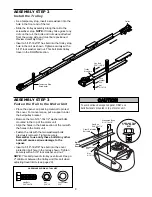

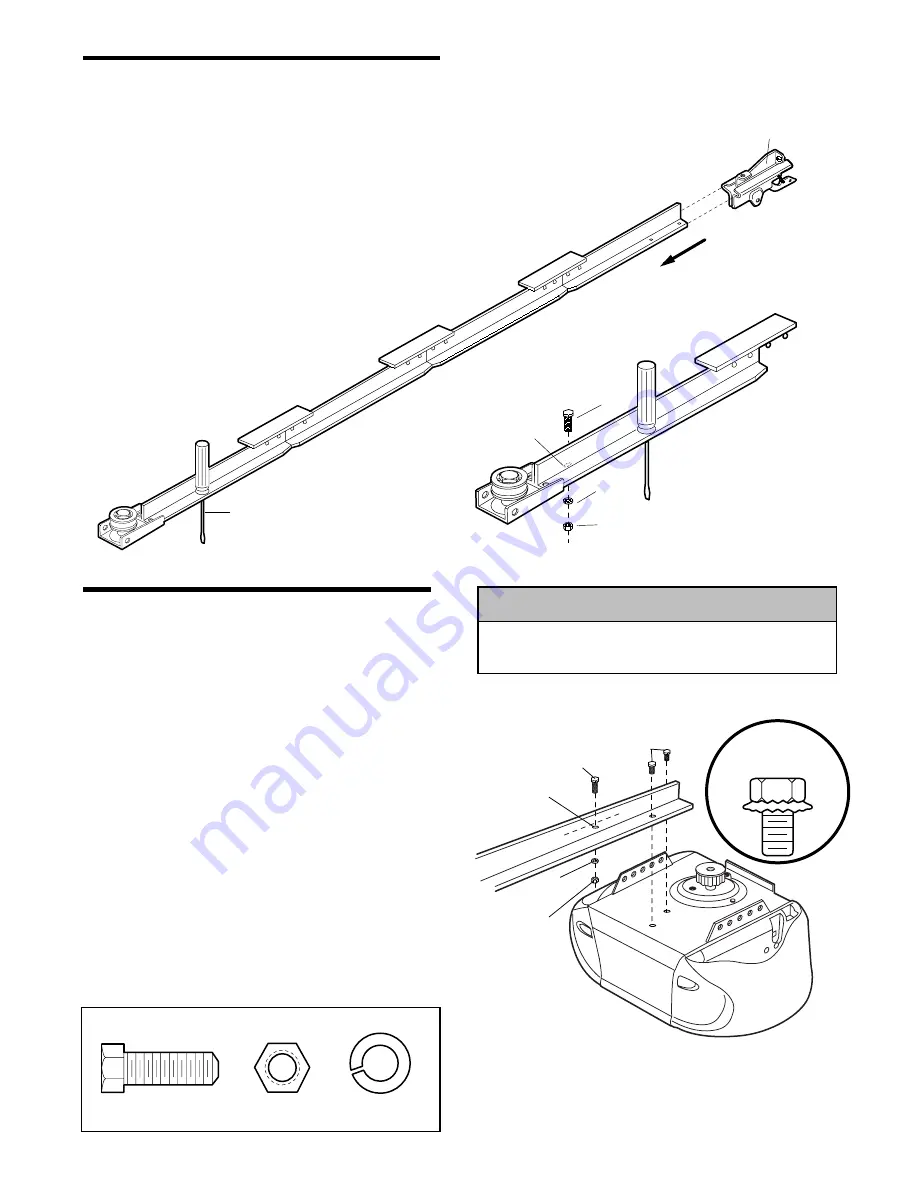

ASSEMBLY STEP 2

Install the Trolley

• As a temporary stop, insert a screwdriver into the

hole in the front end of the rail.

• Slide the trolley assembly along the rail to the

screwdriver stop. NOTE: If trolley hits against any

nuts on the rail, the bolts and nuts were attached

from the wrong side and must be repositioned.

Review Assembly Step 1.

• Insert a 5/16"-18x7/8" hex bolt into the trolley stop

hole in the rail as shown. Tighten securely with a

5/16" lock washer and nut. This bolt limits trolley

travel in the DOWN direction.

Trolley

Temporary Stop

Screwdriver

Hex Bolt

5/16"-18x7/8"

Trolley

Stop Hole

Lock

Washer

5/16"

Nut

5/16"-18

ASSEMBLY STEP 3

Fasten the Rail to the Motor Unit

• Place the opener on packing material to protect

the cover. For convenience, put a support under

the belt pulley bracket.

• Remove the two 5/16"-18x1/2" washered bolts

mounted in the top of the motor unit.

• Align the holes in the back section of the rail with

the holes in the motor unit.

• Fasten the rail with the two washered bolts

previously removed. Tighten securely.

Remember to use only these bolts! Any other

bolts will cause serious damage to the

opener.

• Insert a 5/16"-18x7/8" hex bolt into the cover

protection bolt hole in the rail as shown. Tighten

securely with a 5/16" lock washer and nut.

NOTE: This bolt prevents trolley over-travel. Keep a

2" minimum between the trolley and this bolt when

adjusting travel limits (see page 28).

USE ONLY THIS

TYPE AND SIZE

BOLT

Washered Bolts

5/16"-18x1/2"

Rail

(Back

Section)

Cover Protection

Bolt Hole

Nut

5/16"-18

Hex Bolt

5/16"-18x7/8"

Lock Washer

5/16"

Nut

5/16"-18

Lock Washer

5/16"

Hex Bolt

5/16"-18x7/8"

HARDWARE SHOWN ACTUAL SIZE

To avoid serious damage to opener, ONLY use

bolts/fasteners mounted in top of motor unit.

WARNING

CAUTION

WARNING

WARNING