3

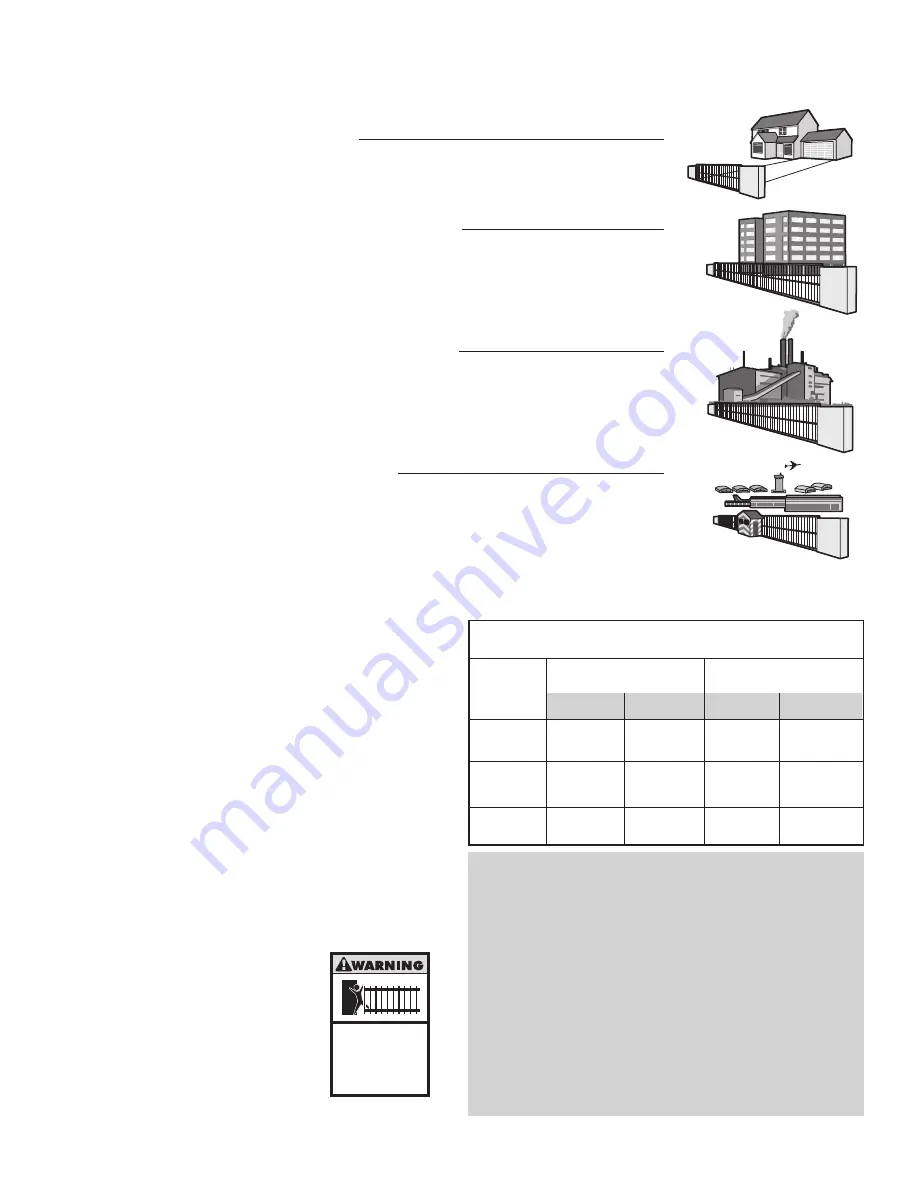

CLASS I – RESIDENTIAL VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a home of one-to four single family dwellings, or a garage or

parking area associated therewith.

I

II

III

IV

CLASS II – COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a commercial location or building such as a multi-family housing unit

(five or more single family units) hotel, garage, retail store or other building servicing the general public.

CLASS III – INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a industrial location or building such as a factory or loading dock

area or other location not intended to service the general public.

CLASS IV – RESTRICTED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a guarded industrial location or building such as an airport security

area or other restricted access locations not servicing the general public, in which unauthorized access is prevented via

supervision by security personnel.

SAFETY ACCESSORY SELECTION

All UL325 compliant LiftMaster gate operators will accept external entrapment

protection devices to protect people from motorized gate systems. UL325 requires

that the type of entrapment protection correctly matches each gate application.

Below are the six types of entrapment protection systems recognized by UL325 for

use on this operator.

ENTRAPMENT PROTECTION TYPES

Type A:

Inherent obstruction sensing system, self-contained within the operator.

This system must sense and initiate the reverse of the gate within two

seconds of contact with a solid object.

Type B1: Connections provided for a non-contact device, such as a photoelectric eye

can be used as a secondary protection.

Type B2: Connections provided for a contact sensor. A contact device such as a gate

edge can be used for secondary protection.

Type C:

Inherent adjustable clutch or pressure relief valve.

Type D: Connections provided for a control requiring continuous pressure to

operate the operator open and close.

Type E:

Built-in audio alarm. Examples include sirens, horns or buzzers.

NOTE:

UL requires that all installations must have

warning signs placed in plain view on both sides of the

gate to warn pedestrians of the dangers of motorized

gate systems.

Moving Gate Can Cause

Injury or Death

KEEP CLEAR!

Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance

The chart above illustrates the entrapment protection requirements for each of the

four UL325 classes.

In order to complete a proper installation you must satisfy the entrapment

protection chart shown above. That means that the installation must have one

primary means of entrapment protection and one independent secondary means of

entrapment protection. Both primary and secondary entrapment protection

methods must be designed, arranged or configured to protect against entrapments

in both the open and close directions of gate travel.

For Example:

For a slide gate system that is installed on a single-family

residence (UL325 Class I) you must provide the following: As your primary type of

entrapment protection you must provide Type A inherent (built into the operator)

entrapment sensing and at least one of the following as your secondary

entrapment protection: Type B1- Non-contact sensors such as photoelectric eyes,

Type B2- Contact sensors such as gate edges or Type D- Constant pressure control.

Class

I & II

Class III

Class IV

A, B1, B2, C or D A, B1, B2, C, D or

E

A, B1, B2, D or E

A, B1, B2 or D

A, B1 or B2

A, B1, B2, D or E

A, B1, B2 or C

A, B1, B2, or C

A or C

B1, B2 or D

A

Slide Gate Operator

Swing & Gate Barrier

(Arm) Operator

UL325

Installation

Class

Primary

Type

Secondary

Type

Secondary

Type

Primary

Type

A, B1, B2, C, D

or E

SAFETY »

UL325 MODEL CLASSIFICATIONS

GATE OPERATOR ENTRAPMENT PROTECTION

UL325 MODEL CLASSIFICATIONS

UL325 ENTRAPMENT PROTECTION REQUIREMENTS