7.2 Ignition Faults

Model 100 Only

WARNING: BEFORE COMMENCING OR COM-

PLETING ANY ELECTRICAL WORK ON THE

APPLIANCE, IT IS RECOMMENDED THAT THE

BASIC SAFETY CHECKS FOR EARTH CONTINU-

ITY, SHORT CIRCUIT, POLARITY AND RESIST-

ANCE TO EARTH ARE MADE. ALL WORK

CARRIED OUT SHOULD FOLLOW GUIDELINES

LAID DOWN BY THE I.E.E.

The Ignition sequence in the Heater is straight

forward and faults can easily be traced if these

simple steps are followed.

Demand to Heat

Pool Thermostat closed

Boiler Thermostat closed

Ignition Control energised

Flue Stat closed

Overheat Stat closed

Trap not blocked

Pressure Switch open

Fan energised.

Pilot Ignition

Main Burner Ignition

If there is a request to heat the Pool, or if con-

nected, the Space Heating, a mains signal will

appear at the POOL DEMAND or HTG DEMAND

connector in the Heater.

For Pool Heating

If the Pool Thermostat Board finds the Pool is

below the set temperature it will put mains on the

BURNER connection of the Pool Thermostat

Board.This is indicated by the LED on the Pool

Thermostat Board. This is connected to the Ignition

Board at its Ls, (Switched Live) connection and the

boiler will then start its ignition process.

For Space Heating (if connected)

If the Pool Thermostat Board finds the Pool is up to

temperature or it has been set for Heating Priority,

it will put mains on the BURNER and HTR PUMP

connections. This is indicated by the LEDs on the

Pool Thermostat Board. The BURNER signal is

connected to the Ignition Board at its Ls, (Swiched

Live) connection and the boiler will then start its

ignition process. The HTR PUMP signal is used to

move the 3 way valve to Heating.

Ignition

Both the 100 and the100W follow the same se-

quence however there are indicators on the 100 to

show these steps. The description below uses the

100 to describe the process.

Lamps on the edge of the Ignition Board indicate

the stages in the ignition sequence. Please refer to

the lable inside the Heater.

Permanent live has to be connected to the L

terminal then the Power lamp lights.

A call for heat powers the Ls terminal and the

Running and Pump lamps light.

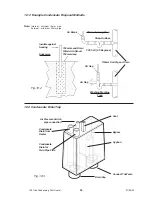

Provided the Flue Stat, Overheat Stat and Heater

are cold, the fan starts up. The pressure switch

detects the correct airflow and that the condensate

drain is not blocked then, switches over. This is

indicated by the Fan lamp illuminating.

The Pilot lamp illuminates, the pilot gas valve

opens and the Ignition Control Board provides a

spark at the pilot electrode.

(If the L and N supply are

reversed the Heater will not progress beyond pilot

ignition. This is indicated by the Phase Reversed neon

behind the knob lighting.)

The pilot flame is detected and the Ignition Control

Board stops sparking and then energises the main

gas valve and the Burner lamp is illuminated.

The pilot flame lights the burner, and it stays alight

until turned off by the control thermostat, system

controls, or in the case of a fault condition a safety

thermostat.

The flue thermostat will trip if the flue exceeds a

pre-set temperature. The overheat thermostat will

trip if the water flow rate is insufficient, both are

indicated by the Lockout lamp illuminating.

NOTE: The Heater has a built-in delay timer. It is

indicated by the Running lamp flashing.

For testing, switching the Mains Supply off for a few

seconds, then back on again will reset the delay.

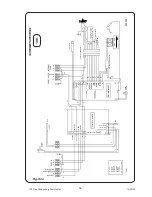

Fault Diagnosis

The fault Diagnosis chart shows the normal and

fault sequences for the Ignition Board indicator

lamps.

To diagnose a fault, use the following procedure.

•

Turn off the system Mains supply.

•

Set all thermostats and timers to a call for

heat position.

•

Turn on the system Mains supply and watch

the Ignition Board indicator lamps.

Compare the lamps with the diagnosis chart oppo-

site to determine the fault and cause.

23

100 Gas Condensing Pool Heater

20/10/03