SKU 46309

Page 9

For technical questions, please call 1-800-444-3353.

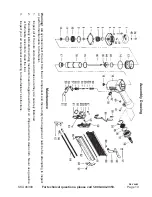

NOTE

: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM AND

TROUBLESHOOTING GUIDE IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE

MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY

KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT

OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE

MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND

NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF

HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Parts List

Part

Description

1

Exhaust

2

Screw

3

Washer

4

Cylinder Cap Assembly

5

Seal Air

6

Compression Spring

7

Gasket

8

O-ring

9

O-ring

10

Head Valve Piston

11

O-Ring

12

Stopper

13

Collar

14

O-ring

15

O-ring

16

Cylinder

17

Bumper

18

Body

19

Nozzle

20

Cover

21

Trigger Axle Head

22

Spring

23

O-Ring

Part

Description

24

Trigger Valve Stem

25

O-Ring

26

Valve Guide

27

Releasing Blade

28

E-ring

29

Trigger

30

Spring Pin

31

Step Pin

32

Frame

33

Spring Pin

34

Stopper

35

Filter Net

36

O-ring

37

Bottom Cap

38

Air Inlet

39

Screw

40

Washer

41

Pin

42

Spring

43

O-ring

44

Piston Head

45

Step Pin

46

Drive Pin

Part

Description

47

Screw

48

Cover II

49

Quick Release Lever

50

Spring

51

Driver Guide Cover

52

Driver Guide

53

Screw

54

Spring Pin

55

Spring

56

Safety

57

Screw

58

Retaining Spring

59

Support

60

Magazine

61

Steel Bar

62

Magazine Side Cover

63

Cover

64

Spring

65

Spring Pin

66

Pusher Guide

67

Pusher

68

Screw

69

Hex Nut

REV 04/05