3

Incorrect choice of die profile will result in tool damage and/or affect the quality of the

crimped joint, leading to potential failure

2.4) Cable preparation:

- Cut the cable perpendicular to the central axis.

- Neatly strip the insulation over a distance equal to the barrel length allowing an additional

10%. Ensure all traces of the insulation are removed. Avoid damage to the outer layer of con

ductor strands.

- Clean the conductor carefully.

- Sector-shaped conductors must be pre-rounded

before crimping.

2.5) Crimping procedure:

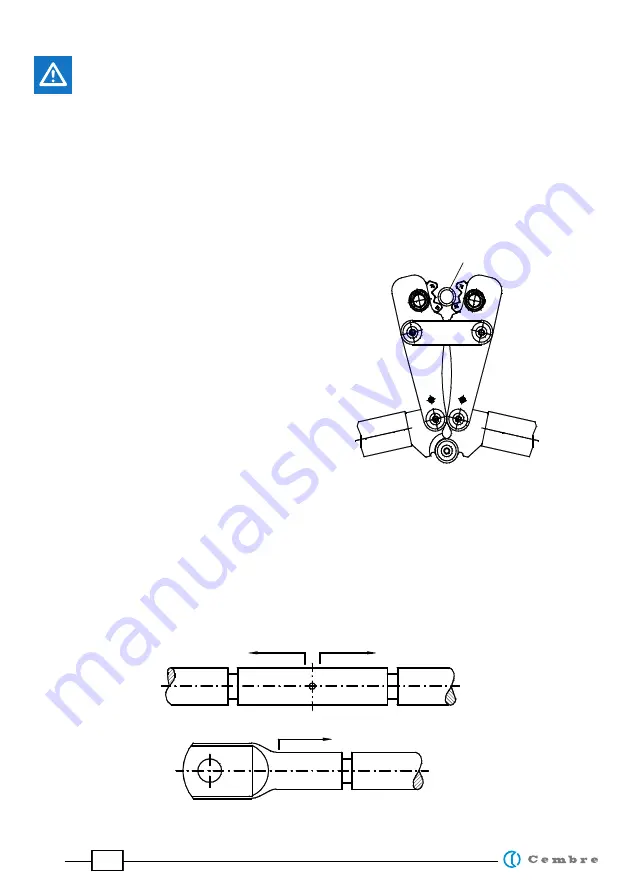

Open the crimping tool handles and position the

connector at the lower part of the die profile (see

image). The terminal lug/splice axis should be per-

pendicular to the plane of the die profile

- Apply a small pressure to the handles to close the dies sufficient to trap the connector

- Fully insert the conductor into the connector barrel.

- Apply sufficient force to close the handles and cause the dies to compress the connector and

conductor until the die profiles become in contact.

- Apply the correct number of compressions as defined on page 4, in the direction defined in

the figure below.

- The crimping bite width is 5mm for these tools.

Arbeitsrichtung beim Verpressen

DIRECTION OF THE COMPRESSIONS

Connector