3

2.

INSTRUCTIONS FOR USE

RHC131LN-KV

is equipped with a "self-lock" quick male coupler suitable for connection to a hydraulic

pump containing insulating oil from the

Cembre

range.

2.1) Setting

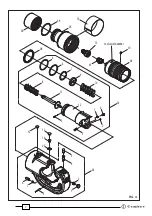

Select the appropriate die set for the connector to be crimped.

Insert the die (91) into the upper seat of the head (FIG. 1) until secured by the retaining pin (07).

To ease the die insertion keep release pin (03) depressed.

Insert the die (90) into the seat on the ram until secured by the retaining pin (06).

To ease this operation, operate the pump to advance the ram (02) 15-20 mm (0.6 - 0.8 in.) and

keep release pin (05) depressed.

2.2) Insulated fl exible hose connection

(FIG. 2)

RHC131LN-KV

is supplied with a specifi c fl exible insulated hose to connect it to the pump.

The moveable ring nut (06) must be used to protect the quick couplers connection from accidental

contact with live conductors.

To connect the fl exible hose:

Turn the moveable ring nut (06) up against the head to locate the quick coupler (FIG. 2a).

Connect the fl exible hose provided to quick coupler of the head (FIG. 2b).

Fully rotate the ring nut (06) up against the collar (20) at the end of the hose (FIG. 2c).

Before using the head, make sure that the ring nut (06) is fully against the collar (20) of the

fl exible hose (FIG. 2c)

2.3) Die advancement

Insert the conductor into the connector (FIG. 3).

Locate the connector between the dies at the desired crimp position (FIG. 4).

Operate the pump to advance the die.

Make sure the dies are exactly positioned on the desired crimp point, otherwise re-open dies

following instructions as per section 2.5 and reposition the connector.

2.4) Crimping

Operate the pump to advance the ram until the die faces touch.

It is recommended to continue pumping until the maximum pressure valve of the pump is

activated.

NOTE

: when more com-

pression is required, proceed

according to the sequence

and direction indicated in the

fi gure, uniformly spacing the

compressions.

2.5) Die opening

Fully discharge the oil pressure from the pump, to retract the ram and release the crimped con-

nector.

1 2

1 2

2 1

connector

connector

conduc

tor

conduc

tor